Automatic Deburring Machine | Manufacturers’ Best Friend MAX Systems' Advanced Cycle

Automatic deburring machine for small, large, and complex parts. Unlike other manufacturers, James Engineering has full in-house control allowing for a fully optimized deburring machine.

MAX Systems' Advanced Cycle

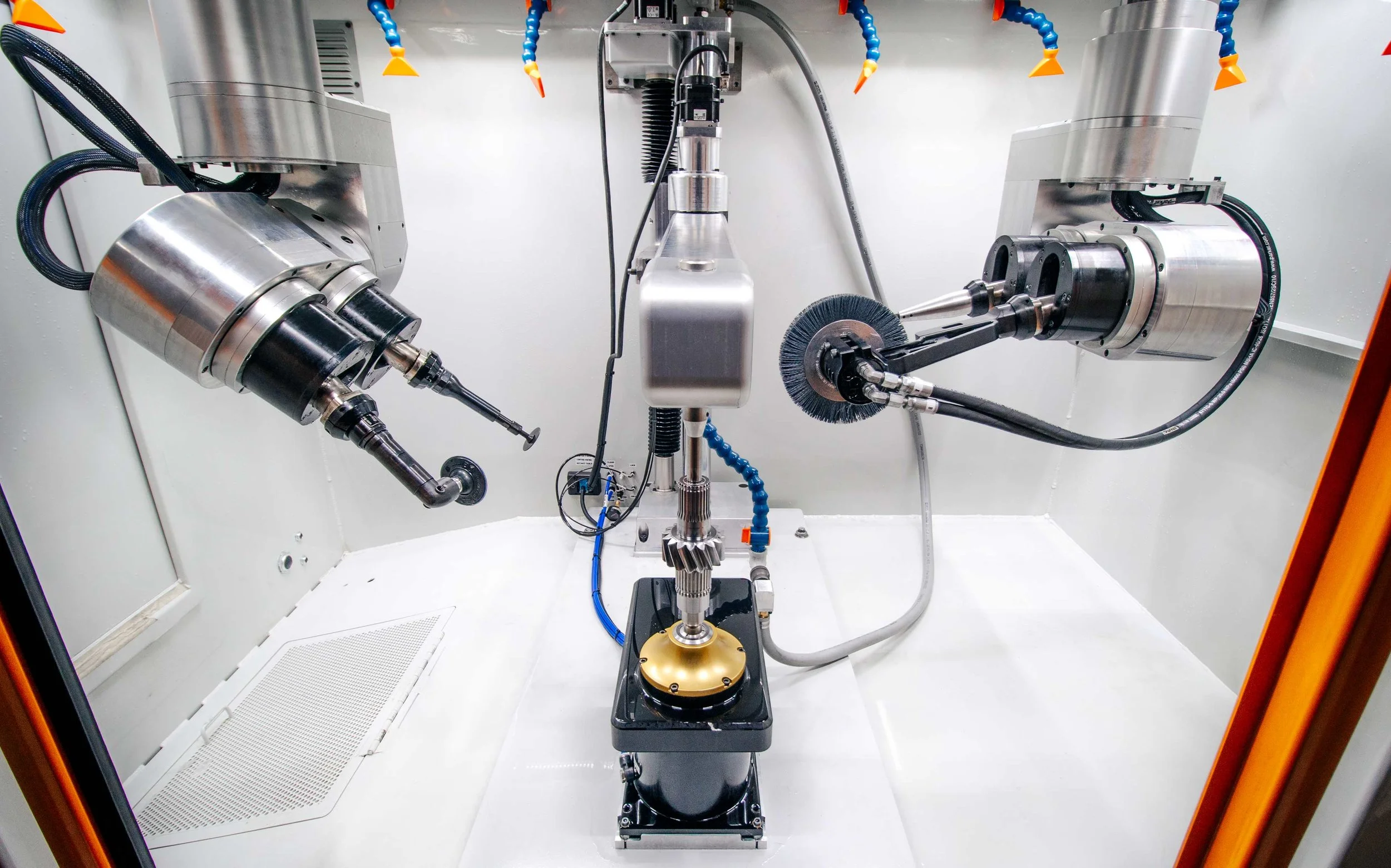

Whether the need is a deburring machine for small parts, complex parts, or components the size of a building, James Engineering has engineered the most versatile deburring machine for sale to date. This automated deburring machine goes above and beyond allowing for a quick swapping of an unlimited array of tools. With a James machine these tools can not only debur but also chamfer, radius, polish, and perform other finishings on various metals and materials. Take a look at our recent cycle we created for a heavily burred part.

Within intricate metal component manufacturing, the presence of burrs poses a persistent challenge. These tiny protrusions can ruin the integrity and functionality of components, demanding efficient removal methods. James Engineering’s MAX Systems introduces a game-changing approach with its advanced deburring cycle, redefining precision and efficiency in the manufacturing process.

The MAX Systems Deburring Cycle:

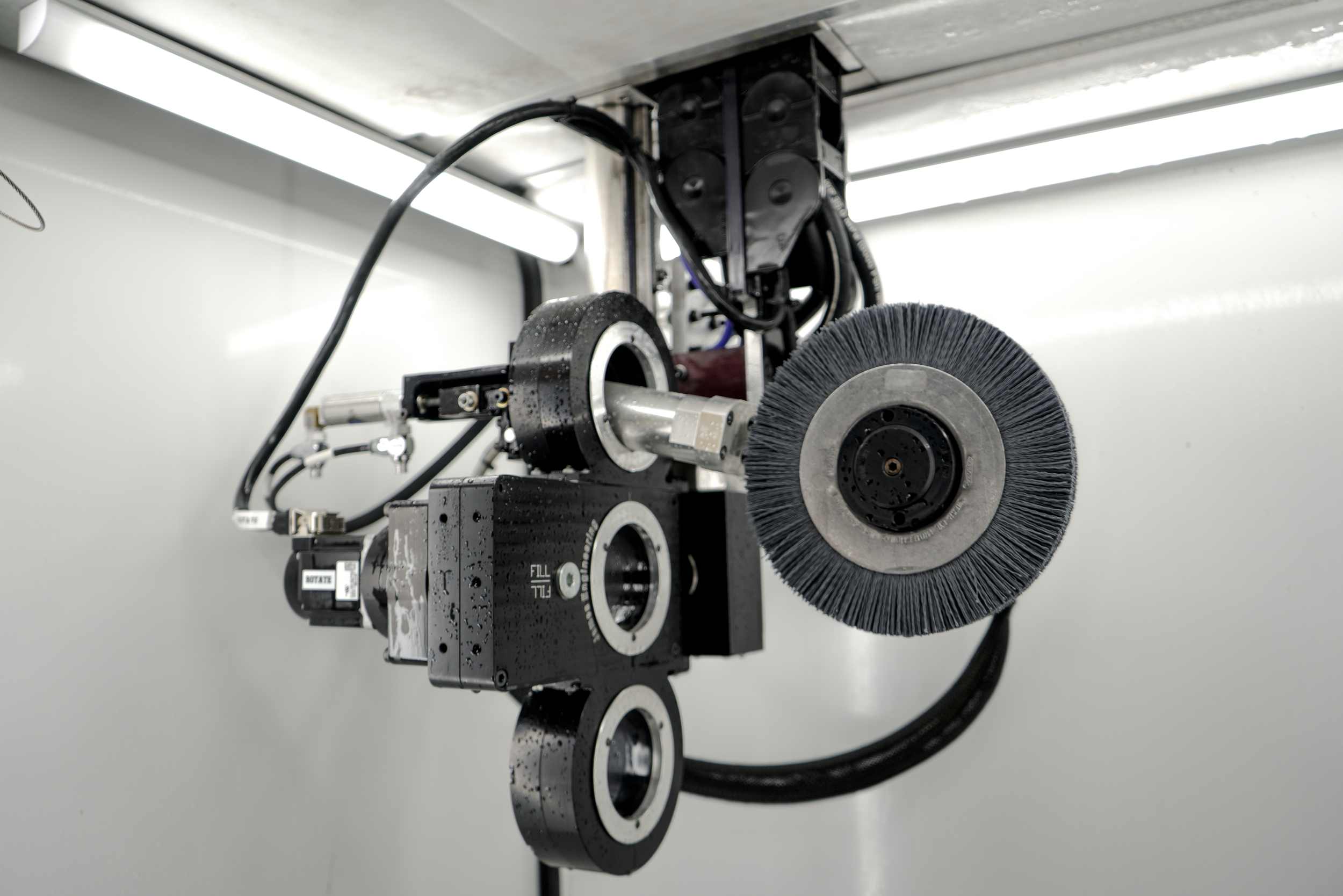

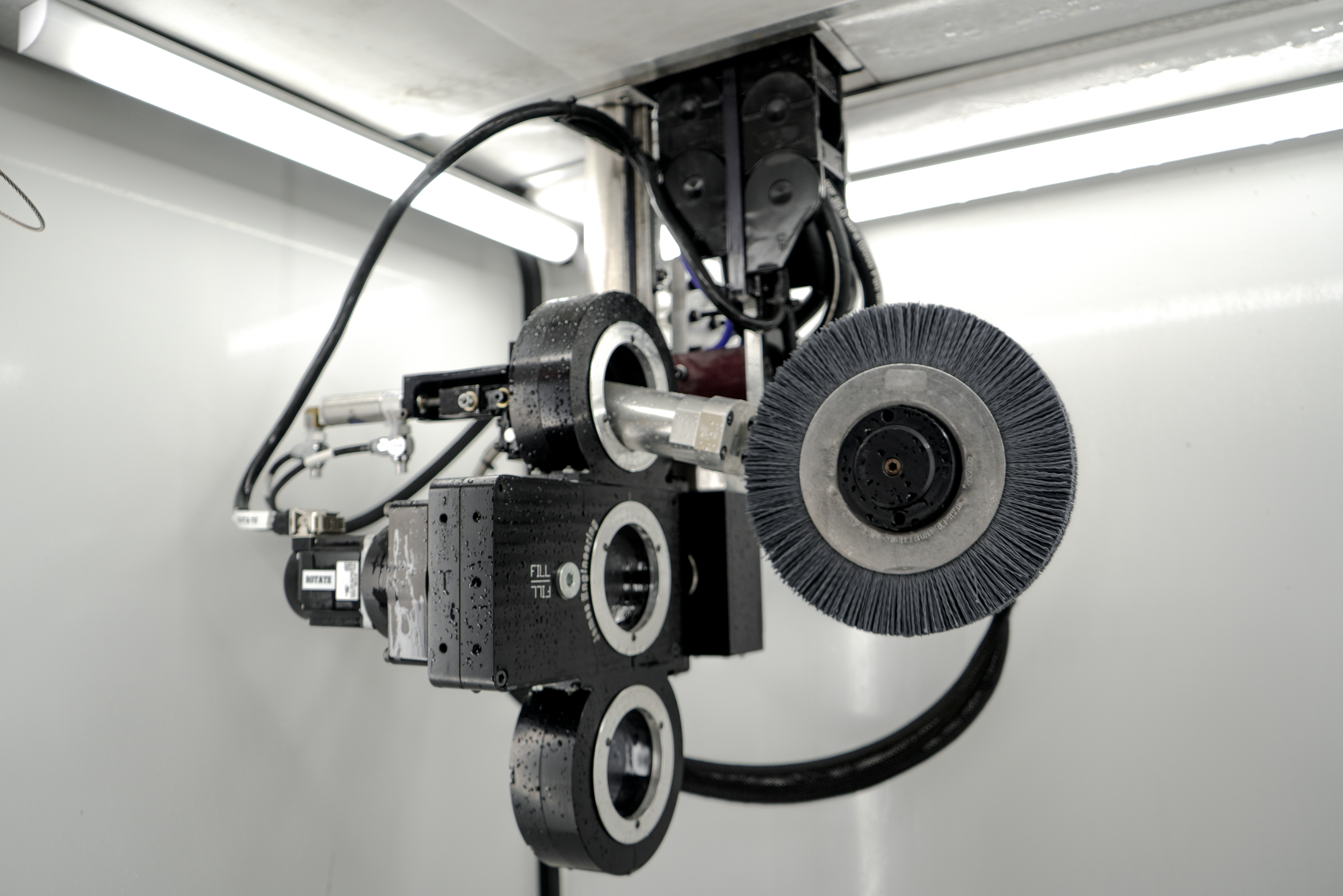

The MAX Systems' crafted deburring cycle is designed to seamlessly remove burrs with unparalleled precision and efficiency. This cycle represents an advancement in deburring operations, offering a unique solution that challenges and defeats these stubborn burrs.Unlike conventional deburring methods, MAX Systems' cycle offers 360-degree coverage, targeting burrs from every angle with precision. Utilizing an overhead servo and specialized brush, the cycle ensures thorough removal of even the toughest burrs, leaving components flawless and ready for further processing.

Dynamic Rotary Table:

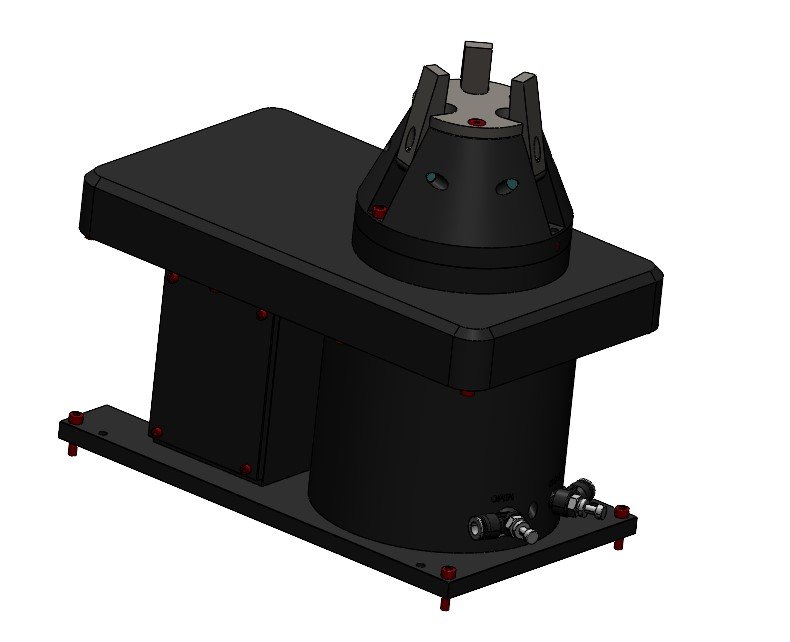

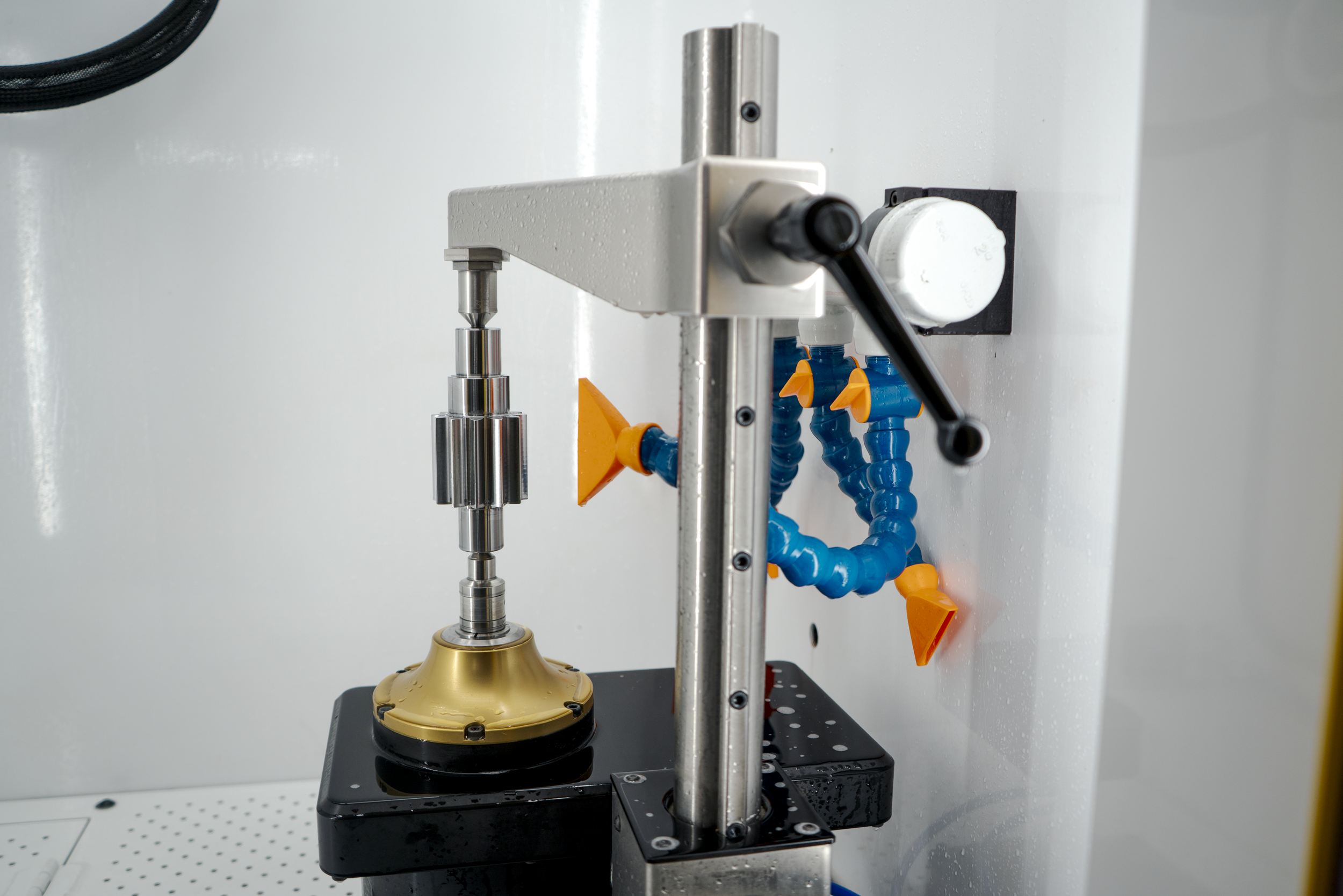

Central to MAX Systems' deburring cycle is the dynamic 5rpm to 1000rpm rotary table, a testament to our commitment to excellence. This feature not only facilitates swift burr removal but also switches directions to address any missed imperfections. By seamlessly alternating directions, the cycle ensures comprehensive deburring, minimizing the risk of defects and enhancing component quality.

Effortless Operation and Swift Setup:

MAX Systems' deburring cycle streamlines operations with its quick load mechanism and user-friendly interface. With a simple push of a button, operators can initiate the cycle, eliminating the need for complex setups and intricate procedures. This streamlined approach ensures the quickest setup with an effortless operation, maximizing productivity on the manufacturing floor with no more loss of time.

Optimized Speed and Consistency:

MAX Systems' deburring cycle is optimized for speed, efficiency, and consistency, revolutionizing the manufacturing process. Each operation is calibrated to minimize processing time while maximizing output quality. The result is a seamless workflow characterized by rapid turnaround and unmatched results, ensuring consistent performance across all manufacturing runs.

Conclusion:

MAX Systems' advanced deburring cycle represents a leap in manufacturing technology, offering a comprehensive solution to the challenges posed by burrs. With its effortless operation, 360-degree coverage, and dynamic rotary table, the cycle redefines the standards of precision and efficiency in deburring operations. Experience the future of manufacturing with MAX Systems—a testament to innovation, reliability, and excellence.

Defense Manufacturing: Fortifying the Front Line of Defense

What is National Defense Transportation Day? It is more than just a date on the calendar; it symbolizes the backbone of our nation’s security infrastructure. What is Armed Forces Day? Click to learn more about

Manufacturing for the Defense Industry: The Engine of Innovation and Security

As we commemorate the days of National Defense Transportation Day on May 17, and Armed Forces Day on May 18, it’s a time to reflect on the critical roles these industries play in safeguarding our nation and to recognize the unsung heroes who make it possible. This article delves into the intricacies of defense transportation, the valor of our armed forces, the vital role of manufacturing in defense, and the innovative contributions of companies like James Engineering in supporting these efforts.

National Defense Transportation: The Lifeline of Security

What is National Defense Transportation Day? It is more than just a date on the calendar; it symbolizes the backbone of our nation’s security infrastructure. From moving troops swiftly to disaster relief operations, defense transportation ensures readiness and response on a global scale. Keywords like logistics, supply chain management, and strategic mobility are not just buzzwords but lifelines in times of crisis and conflict.

Armed Forces Day: Honoring Sacrifice and Service

What is Armed Forces Day? On this day we pay homage to the men and women who serve with unwavering dedication and bravery. Their commitment ensures our freedoms and protects our way of life. From land, sea, and air operations to cybersecurity and space defense, the armed forces embody versatility and strength in the face of evolving threats.

Manufacturing for the Defense Industry: The Engine of Innovation and Security

Behind every military advancement lies the prowess of manufacturing. The defense industry relies on cutting-edge technologies, precision engineering, and stringent quality control measures. Yet, manufacturers in this sector face unique challenges, from regulatory compliance to cybersecurity vulnerabilities. Balancing innovation with security demands a constant vigilance and adaptability.

James Engineering: Empowering Defense Manufacturing Excellence

Click Here to learn about specialized CNC Machines that are playing a pivotal role in military defense manufacturing

Amidst these challenges, companies like James Engineering play a pivotal role. Their expertise in providing advanced finishing solutions elevates manufacturing standards, ensuring the durability, reliability, and performance of critical defense equipment. By partnering with leading manufacturers, James Engineering contributes to the seamless integration of technologies that empower our armed forces worldwide.

A Unified Vision for Security and Progress

As we celebrate National Defense Transportation Day and Armed Forces Day, let us remember that security is not just about strength but also about innovation, collaboration, and resilience. By honoring the past, embracing the present, and innovating for the future, we uphold the ideals of security and progress that define our nation and inspire generations to come.

WHAT IS DEBURRING?

What is Deburring? What is the Deburring Process? Exploring Deburr Techniques, Deburring Challenges, and Deburring Solutions!

What is the deburring process?

Exploring Deburr Techniques, Deburring Challenges, and Solutions!

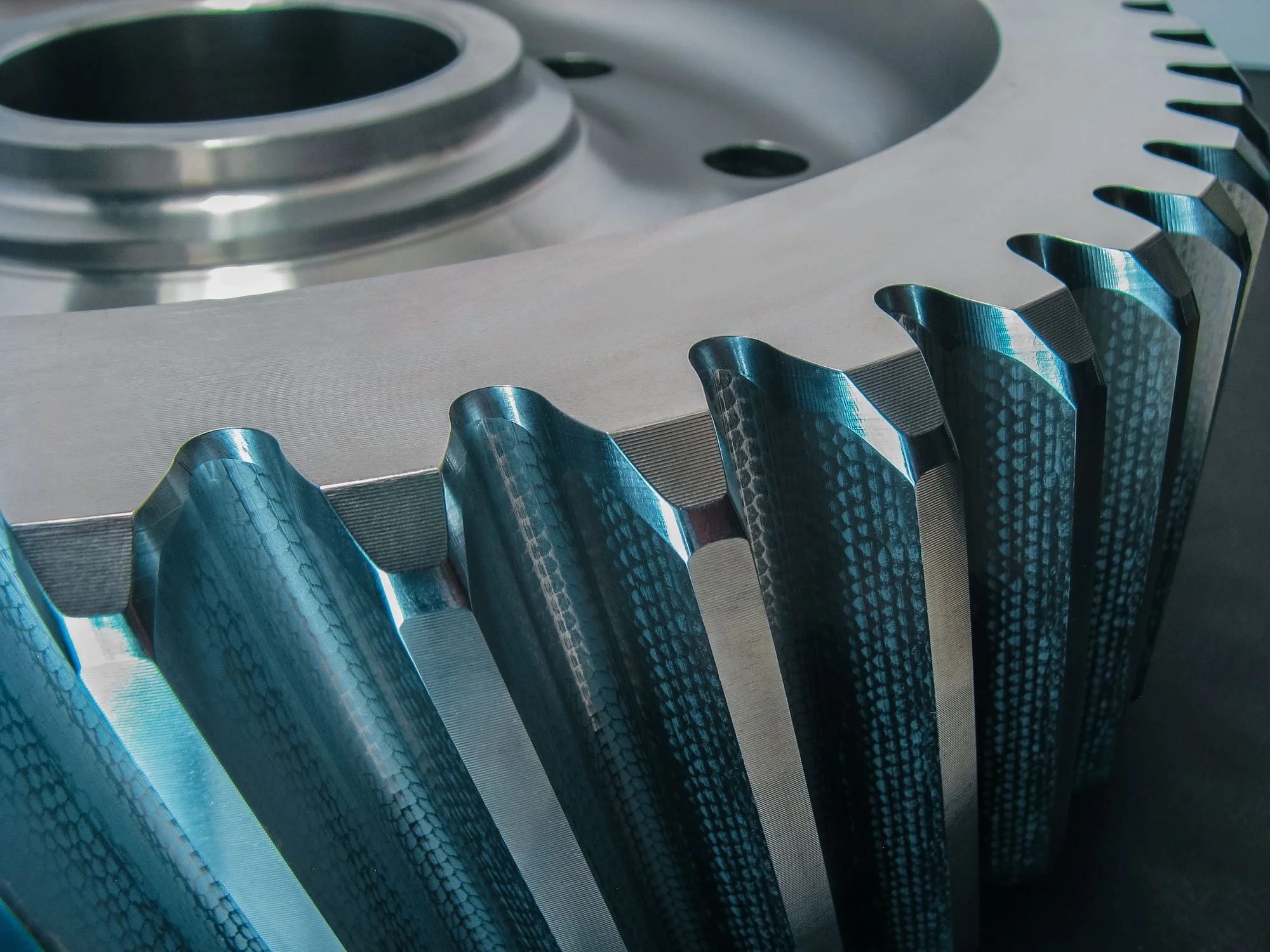

Imagine crafting external gears that mesh seamlessly, internal gears that turn smoothly, or gearboxes that power machines with precision. The secret sauce to this seamless operation? It's all about deburring, a crucial but often underestimated process.

When you dive into manufacturing parts like external gears, internal gears, pinions, pinion shafts, or gearboxes, you're essentially crafting the building blocks of functionality. Every imperfection, no matter how small, can impact the overall performance. That's where deburring steps in, ensuring that these components meet the highest standards of quality and reliability.

Detail of a metal burr. Metal burrs must be removed to ensure safety, functionality, quality control, and optimal performance of metal gears or components in engineering applications.

Understanding Deburring

What is deburring? Deburring is the method of removing unwanted burrs—tiny, often sharp, imperfections—from machined parts. These burrs can result from various manufacturing processes like CNC machining, plasma cutting, or casting. If left untreated, burrs can compromise part functionality, aesthetics, and safety.

Types of Deburring Techniques

Exploring Deburring Techniques and Challenges

Manual Deburring: This traditional method requires skilled operators using tools like scrapers, files, and brushes to remove burrs. While it allows for precision, it is labor-intensive and can be time-consuming, limiting its scalability for large production volumes.

Machine Deburring: Automated deburring machines offer consistent and efficient burr removal, making them indispensable in modern manufacturing. However, challenges such as complex part geometries and varied burr sizes require advanced technologies for optimal results.

Chemical Deburring: While effective for selective burr removal, chemical deburring demands careful handling of chemicals and disposal, requiring strict adherence to safety and environmental regulations.

Abrasive Deburring: Utilizing abrasive materials for mechanical burr removal can generate heat and friction, leading to potential surface damage or tool wear over time.

Electrochemical Deburring (ECM): Although precise, ECM setups can be costly to implement and maintain, requiring skilled technicians for operation and maintenance.

Thermal Deburring: While effective, thermal deburring methods like flame deburring may introduce heat-related distortions in parts, necessitating additional quality control measures.

Cryogenic Deburring: While innovative, cryogenic deburring requires specialized equipment and expertise in handling cryogenic fluids, adding complexity and cost to the process.

Ultrasonic Deburring: While capable of reaching intricate areas, ultrasonic deburring may struggle with harder materials or thicker burrs, requiring adjustments or supplementary processes.

Brush Deburring: While versatile, brush deburring methods may require frequent tool changes or maintenance, impacting production uptime and efficiency.

Waterjet Deburring: While precise and non-destructive, waterjet deburring may struggle with certain materials or intricate geometries, requiring careful process optimization.

The best machine deburring solution combines multi-axis capability with compliant technology. Unlike rigid robotic systems, multi-axis machines with compliant features offer greater flexibility to adapt to varying part geometries and burr locations. They can adjust tool angles and pressures dynamically, ensuring consistent and precise deburring across different parts. Additionally, machines with various tool options provide versatility, allowing for the use of different deburring methods depending on the part's specific requirements. This flexibility translates to improved productivity, reduced setup times, and enhanced overall quality in the deburring process.

Challenges in Deburring

Despite its importance, deburring poses several challenges:

Complex Part Geometries: Components like external gears, internal gears, and gearboxes often feature intricate geometries, making manual deburring impractical and time-consuming.

Burr Consistency: Burrs can vary in size, shape, and location, requiring tailored deburring solutions for optimal results.

Time and Cost: Manual deburring is labor-intensive and prone to inconsistencies, leading to increased production time and costs.

Automated Deburring Solutions

Automated deburring machines equipped with multi-axis compliant technology, like The MAX, offer unparalleled advantages over traditional deburring methods.

Here's a closer look at why they stand out:

Precision: Multi-axis compliant technology integrates CNC deburring tools into automated machines, ensuring precise burr removal even in complex part geometries like pinions and pinion shafts. This precision enhances part quality and functionality, meeting industry standards effectively.

Consistency: These machines deliver consistent results across batches, reducing rework and ensuring consistent part quality. This reliability is crucial for maintaining product integrity and customer satisfaction.

Efficiency: By automating the deburring process, manufacturers save time, reduce labor costs, and boost overall production efficiency. This efficiency improvement is key for meeting production targets and staying competitive in the market.

Flexibility: Multi-axis compliant technology allows for versatile tool movements, adapting to different part shapes and sizes seamlessly. This flexibility optimizes workflow and resource utilization, enhancing productivity and reducing downtime.

Quality Assurance: With precise control and monitoring capabilities, multi-axis compliant machines ensure stringent quality standards are consistently met. This quality assurance is vital for industries demanding precision and reliability, such as automotive, aerospace, and medical device manufacturing.

The integration of multi-axis compliant technology elevates deburring processes to new levels, offering unmatched precision, consistency, efficiency, flexibility, and quality assurance in modern manufacturing environments. These advantages make them indispensable tools for achieving superior results in part finishing and production optimization.

Choosing the Right Deburring Equipment

When selecting deburring equipment, consider factors such as part complexity, production volume, and budget. Consult reputable deburring machine manufacturers like James Engineering, the deburr master known for their innovative deburring solutions tailored to various industries' needs. Top manufacturing companies go to the deburring experts for the best deburring machines.

Need a Chamfering Machine? Click Here

Burr Removal Methods

Exploring Deburring Tools and Techniques

When it comes to precision manufacturing, the right deburring tools and techniques are essential for achieving flawless finishes and optimal part functionality. Let's delve into the various deburring tools and their unique capabilities:

Deburring Brushes: Specialized brushes designed for deburring tasks effectively remove burrs from machined parts, ensuring smooth and precise edges crucial for product quality and performance.

Abrasive Wheels: Utilizing abrasive materials, such as grinding wheels or belts, abrasive deburring tools remove burrs and imperfections from metal surfaces, providing a consistent and uniform finish.

Chamfering Tools: Chamfering tools bevel edges, improving part aesthetics and reducing sharp edges, enhancing safety during handling and assembly processes.

Radius Forming Attachments: These attachments create precise radii on parts, essential for components like gearboxes and mechanical parts where rounded edges are critical for functionality and longevity.

Polishing Equipment: Polishing tools and materials, such as polishing brushes or compounds, achieve high-quality surface finishes, enhancing part appearance and meeting stringent industry standards.

Filing Tools: Filing tools are used to remove excess material and refine surfaces, maintaining precise dimensions and ensuring smooth edges for seamless part integration.

Washing Systems: Integrated washing systems clean parts thoroughly, removing debris, contaminants, and residual materials post-deburring, ensuring optimal cleanliness for subsequent processes or assembly.

In conclusion, understanding the deburring process, utilizing advanced deburring machines and tools, and choosing the right deburring method for your application are crucial steps in ensuring high-quality, precise machined parts.

By prioritizing deburring before chamfering, polishing, or other finishing processes, manufacturers can uphold the standards necessary for top-notch products in industries relying on precision components like automotive, aerospace, and machinery manufacturing.

If you are looking for the best deburring machines that have stood the test of time for their durability and used by top manufacturing companies across the world for chamfering and all purpose gear and part finishing.

Contact James Engineering at Sales@James-Engineering.com

Mastering Deburring: From Micro Parts to Massive Gears

In manufacturing, the size of parts can pose substantial challenges when it comes to deburring and chamfering processes.

In manufacturing, the size of parts can pose substantial challenges when it comes to deburring and chamfering processes. Whether you're a manufacturer dealing with delicate medical micro components, large mining gears, or life critical aerospace and defense parts requiring precision, finding the right deburring machine is critical. At James Engineering, we specialize in deburring solutions tailored to handle the diverse needs of modern manufacturing.

Deburring Machine for Small Parts and Micro Components

Deburring and chamfering small parts and micro components demand precision and finesse. Our surface finishing machines are designed with advanced compliance technology to cater to these exacting requirements. From intricate micro parts to precision components, our machines ensure consistent and high-quality results every time. Fully automated features reduce human intervention, freeing up your workforce for more specialized tasks.

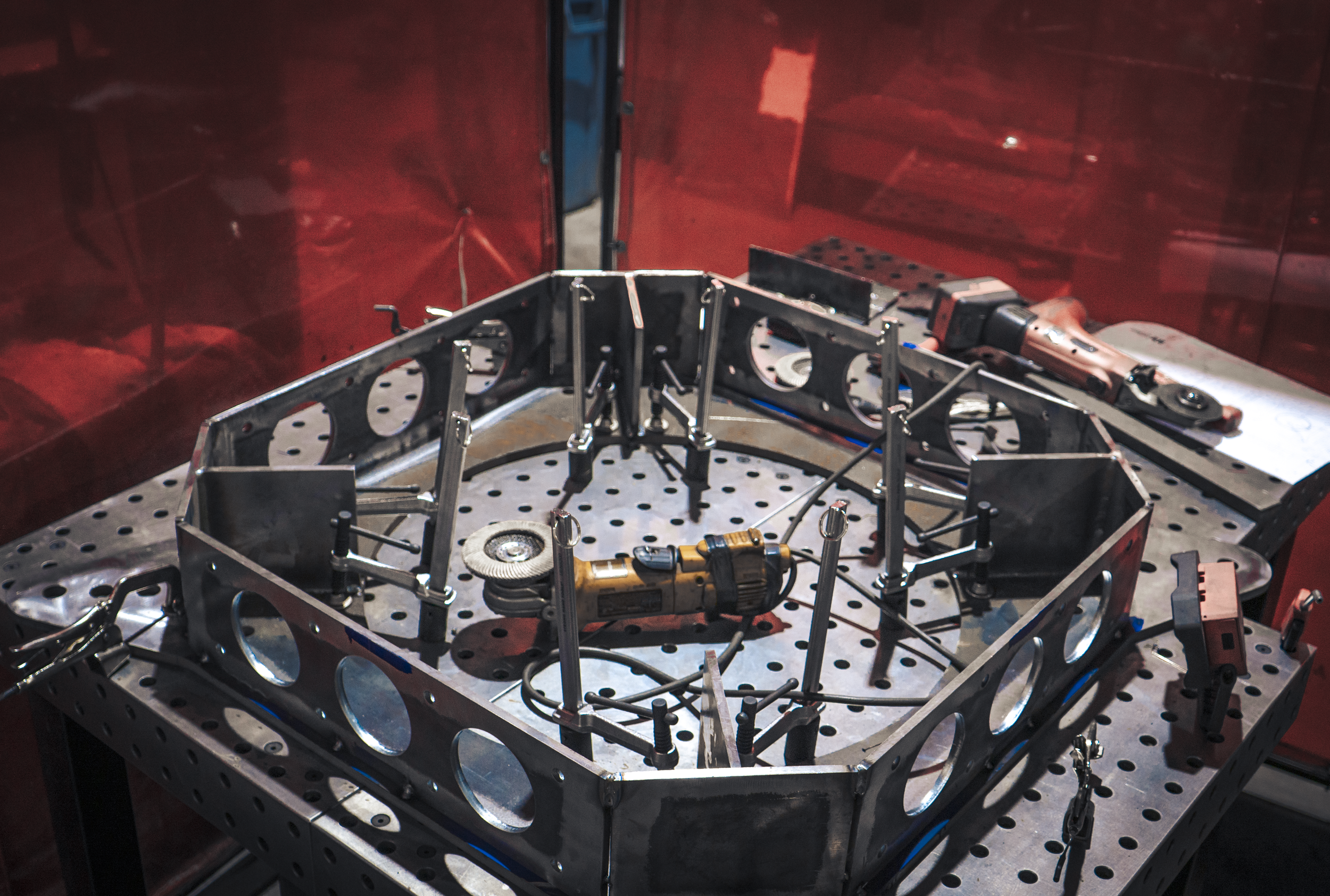

Deburring Machine for Large Gears

Dealing with large gears presents unique challenges in deburring and chamfering. Our specialized large gear deburring machines are equipped to handle these massive components with ease. Automated processes streamline operations, delivering efficient and reliable results while reducing manual labor costs. Consistent deburring of large gears ensures optimal performance and longevity in your machinery.

James Engineering redesigned their famous MAX System with an open back to accommodate large gear deburring and chamfering

Deburring Machine for Aerospace and Defense Parts

In the aerospace and defense industries, precision is non-negotiable. Our deburring machines are engineered to meet the stringent demands of these sectors. Whether deburring intricate aerospace components or critical defense parts, our machines deliver unparalleled accuracy and repeatability. Customizable settings allow for precise adjustments to match specific part requirements, ensuring adherence to strict industry standards.

Wide-Range Surface Finishing Machines

Don't let part size limitations hinder your manufacturing excellence. James Engineering offers specialized deburring machines tailored for small parts, micro components, large gears, and aerospace/defense parts. Experience consistent quality, efficiency, and cost-effectiveness in your deburring processes.

Do I need a Chamfer Machine or a Deburring Machine?

Learn the difference here

Contact us today to explore how our advanced surface finishing technology can elevate your manufacturing operations across diverse part sizes and industries.

Master large gear deburring or small gear finishing with James Engineering's complete deburring solutions!

The Future of Automation in Manufacturing | Machines vs. Human Labor

As manufacturing landscapes evolve, automation emerges as a crucial solution for optimizing processes like deburring and chamfering. This article explores the pressing need for automation in manufacturing, the challenges faced by human labor, and the limitations encountered with traditional robotic systems.

Automation in Part Manufacturing

As manufacturing landscapes evolve, automated deburring emerges as a crucial solution for optimizing processes like machine deburring and machine chamfering. This blog explores the pressing need for automated deburring, the challenges faced by human labor, and the limitations encountered with traditional robotic systems.

The Need for Automated Deburring in Part Finishing

Modern manufacturing demands high levels of efficiency and precision, especially in tasks like deburring and chamfering critical for part quality. Human labor, while skilled, faces challenges such as fatigue, variability, and safety risks. These factors hinder consistent production output and quality assurance, necessitating a shift towards automation.

Challenges of Human Labor

Limitations and Safety Concerns

Manual hand deburring and chamfering tasks are time-consuming and physically demanding, leading to potential errors and variability in results. Moreover, human operators face safety risks associated with handling sharp edges and heavy machinery, impacting both productivity and worker well-being.

Challenges of Industrial Robots

Rigidity and Adaptability

Traditional industrial robots, while efficient in certain tasks, often lack the adaptability required for complex deburring and chamfering processes. Their rigid programming limits flexibility, leading to challenges in handling diverse workpiece geometries and achieving consistent results across different parts.

Focused Deburring

Precision and Adaptability in Automated Deburring

James Engineering experts emphasize the significance of compliant technology in addressing these challenges. Their patented Focused Deburring can adapt to varying workpiece geometries, ensuring precise and consistent results without constant manual adjustments, or the need to mask parts. This adaptability reduces errors, enhances quality control, and streamlines manufacturing processes. Ensuring the next level of precision in deburring machines.

Integrating Automation for Sustainable Manufacturing

The evolution of manufacturing hinges on integrating automation solutions that combine efficiency, precision, and safety. By addressing the limitations of human labor and traditional robotic systems, manufacturers can achieve higher productivity, quality assurance, and workforce empowerment. Experts like James Engineering offer valuable insights and solutions that pave the way for a sustainable and innovative manufacturing future.

See the different system options here.

Contact us to determine which system best suits your manufacturing needs.

The Chamfer Machine Unmatched by All

Gear chamfer machine manufacturers who make an automatic chamfer machine may succeed at efficiency, precision, or sustainability but finding an optimized solution of all three advantages remains elusive. Until now

Chamfer Machine Manufacturers

Automated Chamfer machine manufacturers who make an automatic chamfer machine may succeed at efficiency, precision, or sustainability but finding an optimized solution of all three advantages remains elusive. That however is where the all-purpose MAX System Machine by James Engineering comes in. The MAX System Machine is not just another chamfering tool; it represents a shift in machining technology. Designed to deliver unmatched performance across multiple fronts, the MAX System Machine redefines what is possible in chamfering operations. Not only does it provide a repeatable precision chamfer, but its versatility extends to accommodating an unlimited array of tool heads meant for deburring, polishing, radiusing, other finishes, and more.

Changing Industrial Manufacturing

The reason James Engineering’s machines reach such a high level of optimization could be attributed to their commitment to being a full OEM manufacturer. By producing all components of the machine in-house, James Engineering holds complete control over every feature, ensuring maximum performance and reliability. This also allows for the creation of flexible machines that fit the needs of any customer. Every machine aspect can be configured to optimize any operation.

Efficiency

Efficiency is at the core of the MAX System Machine's design. James Engineering's multi-tool machines are engineered to perform tasks quickly and simultaneously, minimizing cycle times and maximizing productivity. For example, the MAX System M5W consists of two 5-axis overhead servos with two interchangeable tools each. They perform operations simultaneously on a c-axis rotary table, making this a 4-tool 11-axis machine. James’ machines have chamfered and deburred 82 gear teeth on a part in just 30 seconds, including secondary burrs. However, companies love to talk about quick cycle times but are quiet regarding change-out time in between the cycles. James Engineering surpasses this norm of slow downtimes by achieving efficiency that extends beyond cycle speeds. By eliminating setup time and maintaining a saved log of cycles, James Engineering enables seamless transitions for running multiple parts or simply with the push of a button repeating the same part. Each machine is designed with a user-friendly control panel allowing for any operator to run them, regardless of experience. James Engineering also offers fully automated “lights out” machines that require no human operator to run parts, further streamlining operations.

Precision

Precision is another area where the MAX System Machine stands out. With consistent radiuses and cutting-edge compliant technology, James Engineering sets a new standard for precision chamfering. Unlike conventional machines that may struggle with unpredictable variables such as wheel wear or part inconsistencies, the MAX System Machine's patented compliant technology ensures consistent results every time, regardless of external factors. With a huge gain in efficiency, there is no loss in precision, there is quite the opposite. Even on small micro-parts, there is a visual difference when the part is finished on a James Engineering machine. Intricate and oddly shapen parts are also still finished with perfect chamfers and radiuses. These precision finishes minimize part wear and stress points to the fullest extent.

Sustainability

Sustainability is a must in modern manufacturing, and the MAX System Machine delivers on this as well. Programmable cycles, which can be saved as "recipes," ensure perfect cycles every time, eliminating scraped parts and optimizing resources. With optional “wet” cycles, these MAX System machines are equipped with a 150-gallon tank that is filtered and recycled into the next cycle, maximizing the use of the water. Additionally, James Engineering produces their own grinding wheels with a liquid resin that extends part life and promotes even wear. Paired with compliant technology, that won’t over-engage tools, the life of the grinding wheels and various tool heads is greatly extended, further enhancing sustainability efforts.

An Automatic Chamfer Machine like no other

The MAX System Machine by James Engineering remains an industry leader in chamfering and finishing technologies, continuing to advance the manufacturing process. By seamlessly integrating efficiency, precision, and sustainability into a single, innovative solution, the MAX System Machine allows manufacturers to elevate their chamfering and finishing operations to new heights of performance and excellence.

If you’d like to know more reach out and learn how James Engineering can upgrade and take your manufacturing process to the next level. Watch our machine in operation below and see our technologies in action.

The Power of Compliant Technology, the Magic Behind The MAX

There’s major problem in the industry! Find out how we solve it!

See how James Engineering is solving the problem of non-inform parts , watch the video below

Precision is key.

Yet, the reality often falls short of the ideal, with parts turning out to be anything but perfect. Scott Richards, Vice President of James Engineering, delves into the heart of this challenge, shedding light on the industry's persistent problem and the innovative solution James Engineering has developed.

Solving the Problem of Non-Uniform Parts

Watch below as Scott Richards opens the discussion by addressing a common yet critical issue in manufacturing: non-uniformity. Many parts, despite appearing round, lack uniformity in dimensions. This discrepancy poses a significant challenge, particularly in processes like deburring, where precision is paramount.

Traditional approaches, including vision systems and CNC machines with complex algorithms, have failed to adequately address this issue over the past four decades. However, James Engineering's breakthrough compliant technology offers a revolutionary solution.

The Essence of Compliant Technology

Compliant technology mimics the human hand's ability to sense and adapt to surfaces in real-time. Unlike conventional methods reliant on lasers or mathematical equations, compliant technology mechanically senses and reacts to surface variations as they occur. This approach eliminates the need for predictive algorithms and ensures consistent results, even with perishable tools prone to uneven wear.

Navigating the Challenges of Inconsistent Parts

Watch as Scott delves deeper into the complexities of inconsistent parts, emphasizing the significant impact of stress relief in machining processes. As parts undergo machining, stress relief can cause unexpected distortions, leading to mismatches between the intended model and the final product. This disparity poses challenges for CNC machines and robots programmed to expect uniformity.

Addressing the Inconsistency

James Engineering's compliant technology offers a versatile solution to address inconsistencies across various manufacturing processes. By dynamically adjusting to surface variations, the technology ensures precise results, regardless of a part's shape or dimensions. Unlike traditional methods reliant on human intervention, compliant technology offers unparalleled accuracy and repeatability, enhancing overall manufacturing efficiency.

Empowering Manufacturers with Precision

In a competitive manufacturing landscape, precision is non-negotiable. James Engineering's compliant technology empowers manufacturers to achieve unparalleled precision and consistency, revolutionizing traditional manufacturing processes. By eliminating the reliance on manual intervention and predictive algorithms, the technology streamlines operations, reduces costs, and enhances product quality.

Embracing the Future of Manufacturing

As industries evolve and technology advances, embracing innovative solutions becomes imperative for sustained success. James Engineering's compliant technology represents a paradigm shift in manufacturing, offering a glimpse into the future of precision engineering.

Scott Richards's insights into the transformative potential of compliant technology underscore its significance in revolutionizing manufacturing. By bridging the gap between traditional methods and emerging challenges, James Engineering paves the way for a new era of precision and efficiency in manufacturing.

Incorporating compliant technology into manufacturing processes holds the promise of unlocking new possibilities and driving unprecedented levels of efficiency and precision. As industries continue to evolve, embracing such innovations will be crucial for staying ahead of the curve.

Mastering Work-holding: The Advantages of Self-Centering Clamps

In engineering and manufacturing, achieving precision and efficiency is not just desirable; it's crucial for success. As industries evolve, so do the tools and technologies used to streamline processes and save valuable time. One such innovation that has transformed the landscape of workholding solutions is the self-centering clamp. Let's explore their benefits and understand the uses.

In engineering and manufacturing, achieving precision and efficiency is not just desirable; it's crucial for success. As industries evolve, so do the tools and technologies used to streamline processes and save valuable time. One such innovation that has transformed the landscape of workholding solutions is the self-centering clamp. Let's explore their benefits and understand the uses.

Understanding Centering Clamps

Centering clamps, also known as engineering clamps, are indispensable tools in various industries where holding workpieces securely and precisely is essential. Traditionally, clamping mechanisms required meticulous adjustments to ensure proper alignment, often leading to time-consuming setups and adjustments. This is where self-centering clamps step in to revolutionize the game.

Unyielding strength in every grip. The JE heavy-duty Work Station is built to handle 1000+ pounds with ease.

Enter Self-Centering Clamps

Self-centering clamps stand out as a beacon of innovation in the realm of workholding solutions. These ingenious devices are designed to automatically center and secure workpieces with lightning-fast precision, eliminating the need for manual adjustments. This "quik-change" feature ensures lightning-fast change-outs, significantly reducing setup time and increasing productivity.

Time-Saving Benefits

Time is money, especially in the competitive landscape of manufacturing. With traditional clamping methods, precious minutes are spent on meticulous adjustments to achieve the desired alignment. Self-centering clamps, on the other hand, drastically reduce setup time by automatically centering the workpiece with unparalleled speed and accuracy. This means engineers and machinists can devote more time to actual production tasks, maximizing efficiency and output.

Labor Advantages

Labor optimization is another crucial aspect of any manufacturing operation. By incorporating self-centering clamps into the workflow, companies can streamline their processes and make more efficient use of human resources. With reduced setup times and simplified operation, skilled workers can focus on tasks that require their expertise, rather than repetitive manual adjustments.

Versatility and Reliability

Self-centering clamps are renowned for their versatility and reliability. See multiple versions here.

Whether in CNC machining, welding, assembly, or any other application requiring precise workholding, these clamps deliver consistent performance, ensuring repeatable results with minimal effort.

Conclusion

In conclusion, self-centering clamps represent a significant leap forward in workholding technology. Their ability to provide lightning-fast change-outs, coupled with the time-saving benefits and labor advantages they offer, make them indispensable tools in modern manufacturing environments. By embracing innovation and efficiency, companies can stay ahead of the curve and unlock new levels of productivity in their operations.

The Largest Gear In The World | Machining's Biggest Debate

In 2009, scientists at the Institute of Materials Research and Engineering, Singapore, created the world's smallest working gear, controlled at a molecular level. This was officiated by the Guinness World Records, but when it comes to the largest gear, there's a bit of controversy. It's a touchy subject in manufacturing circles, with competing firms often reluctant to discuss.

Tiny to Titan

In 2009, scientists at the Institute of Materials Research and Engineering, Singapore, created the world's smallest working gear, controlled at a molecular level. This was officiated by the Guinness World Records, but when it comes to the largest gear, there's a bit of controversy. It's a touchy subject in manufacturing circles, with competing firms often reluctant to discuss.

Not Your Typical CNC

From towering wind turbines to immense mining equipment, these gears play critical roles in powering, moving, and shaping the infrastructure of modern society. They require specialized and intricate manufacturing, even in post-processing. For example, James Engineering redesigned its state-of-the-art chamfering and deburring machine by adding an open back. This adjustment allows the machines to handle gears or components of any size.

Hofmann Engineering

The Competitors

Some of these gears are so massive they could host an entire manufacturing staff comfortably. Take, for instance, Hofmann Engineering's shipment of a forged steel mill gear, a colossal with a diameter of 13.2 meters, weighing a staggering 73.5 tons. But can they claim the title of the world's largest gear? Not so fast, Rexnord/Falk counters with their 13.5-meter SAG mill gear. Among others, P. Van Der Wegen Gears isn't far behind. But just slightly above all these is Ferry Capitain. Already producing a 13.6-meter girth gear, their machine has the capability of producing a 16-meter gear. So does this mean Ferry Capitain takes the crown? Not quite.

The Debate

A big debate started on a Gear Technology page when someone brought up a 92-meter diameter thickener rack. This brought into question if the thickener rack or dragline rack should even be considered a gear because they themselves don’t rotate. The late Eliot K. Buckingham, an industry authority, wrote, “To my mind, a single gear is a piece of metal with projections on it. A gear is designed to be operated with another gear or gears.” In this light, the world's largest gear might just be a cog railroad, with the rail serving as a rack, this would theoretically be an infinite-sized gear.

Large Gear’s Motive

Depending on how you define a gear, you may still give Ferry Capitain the crown. However, these companies are not building gears for their size. Time has also passed since the creation of those large gears noted. Since these companies aren’t publicly announcing every job, a new victor, producing a custom job, could exist and not even know it. Ultimately, the motive to create these enormous-sized gears boils down to meeting customer needs. If a customer demands a 40-meter girth gear, these companies will deliver. It's what they do. And as technology advances, gears will only get larger, leaving us in awe of what's to come.

Conclusion

Stating who holds the record for the biggest gear might be as elusive as finding the best cup of coffee and until Guinness verifies it with a tape measure, skepticism will remain.

To learn more about large-scale manufacturing Click Here

Chamfer Explained - What is the Purpose of a Chamfer?

Chamfering’s importance is paramount in various fields such as civil engineering, woodworking, and machining. But what exactly is chamfering and what is its purpose?

Chamfering in Engineering

Chamfering’s importance is paramount in various fields such as civil engineering, woodworking, and machining. But what exactly is chamfering and what is its purpose?

Chamfer Definition

Chamfering refers to the process of creating a symmetrical edge by removing a right-angled corner or edge. Depending on component size, this may seem like a simple adjustment, but its implications are profound. Especially in industries like aerospace, automotive, etc; where precision is a must.

(Before/After)

Deburred and Chamfered with a James Engineering Max System

What is The Purpose of Gear Chamfering?

If parts and gears are left with no chamfer sharp angles can exist, posing a serious risk to operability and safety. These angles become stress points and the component becomes vulnerable to damage and fatigue. In machining, impacts, vibrations, and extreme heat exacerbate these risks and can lead to breaks or fractures. Damage like this can impact the performance of the entire machine. With a chamfer, the stress of the sharp edge is appropriately distributed and the risk of damage is eliminated.

Reducing Stress with a Chamfer

As an example, consider a 90-degree angle. Chamfering the angle flat and creating two 45-degree angles significantly decreases the stress of that edge. This minor altercation greatly extends the lifespan of components, ensuring durability and reliability.

90° angle cut to two 45° angles to remove stress point.

Optimizing the Gear Chamfering Process

Even though a chamfer is only a slight alter, chamfering can be a very tedious, time-consuming, and inconsistent process. However, advanced technologies have revolutionized this process. With our MAX automatic and manual gear chamfering machines, chamfering is no longer a challenge–it’s a seamless operation.

Our gear chamfering machines are engineered for an operator of any experience without compromising on precision, quality, efficiency, or sustainability. Whether it’s a large-scale project or a small intricate detailed job, our unique machines are tailored to meet any need. We specialize in custom solutions, whether it’s large single-part batches or varying parts in each cycle, we will fully optimize your process.

Conclusion

Chamfering plays a vital role in enhancing the performance and longevity of components across various industries. By understanding chamfering’s purpose and utilizing advanced technologies, engineers can ensure that their products will withstand the test of time. Reach out to learn how MAX and manual machines can optimize your chamfering process and elevate your operation to new heights.

Chamfer Explained 3D Animation

The Advantage of 11-Axis Machining over 5-Axis Machining in High Precision Part Finishing

In the realm of manufacturing, precision is paramount. Achieving high precision in part finishing not only enhances the quality of the final product but also significantly impacts efficiency and cost-effectiveness. Traditional machining methods have paved the way for advanced technologies like 5-axis machining, and now, the evolution continues with the advent of 11-axis machining. In this article, we delve into the nuances of high precision part finishing and explore the distinct advantages offered by 11-axis machining over its 5-axis counterpart.

In the realm of manufacturing, precision is paramount. Achieving high precision in part finishing not only enhances the quality of the final product but also significantly impacts efficiency and cost-effectiveness. Traditional machining methods have paved the way for advanced technologies like 5-axis machining, and now, the evolution continues with the advent of 11-axis machining. In this article, we delve into the nuances of high precision part finishing and explore the distinct advantages offered by 11-axis machining over its 5-axis counterpart.

Understanding High Precision Part Finishing

High precision part finishing involves the intricate process of refining components to exact specifications, ensuring dimensional accuracy, surface finish quality, and overall performance. This meticulous craftsmanship is vital across diverse industries, including aerospace, automotive, medical devices, and beyond, where precision is non-negotiable.

5-Axis Machining: A Step Forward

5-axis machining revolutionized manufacturing by enabling simultaneous movement of the cutting tool along five axes, allowing for enhanced complexity and flexibility in part production. This technology excels in sculpting intricate geometries and contours with remarkable accuracy, reducing setup time and increasing efficiency compared to traditional 3-axis machining.

The Emergence of 11-Axis Machining and Beyond

Building upon the capabilities of 5-axis machining, Multi-axes machining represents the next frontier in precision manufacturing. By incorporating additional rotational and tilting axes, this advanced technology introduces unprecedented levels of versatility and precision to part finishing processes.

Experience precision in action with James Engineering’s state-of-the-art 11-axis 2 Tower , The MAX, all purpose finishing machine – revolutionizing part finishing for top-tier quality and efficiency.

Benefits of 11-Axis Machining over 5-Axis

Enhanced Complex Geometry Machining: With six additional axes at its disposal, 11-axis machining offers unparalleled freedom in maneuvering the cutting tool around complex part geometries. This capability is particularly advantageous for producing intricate components with challenging features, such as undercuts, draft angles, and compound curves.

Optimized Surface Finish: The increased flexibility of 11-axis machining enables precise control over tool paths and cutting angles, resulting in superior surface finish quality. Fine details and delicate features can be meticulously refined, eliminating the need for secondary finishing operations and reducing overall production time.

Improved Tool Accessibility: Complex part geometries often present challenges in tool accessibility during machining. 11-axis machines address this issue by enabling dynamic tool positioning from multiple angles, ensuring optimal reach and coverage across the entire workpiece. This capability minimizes the need for repositioning and mitigates the risk of tool interference, enhancing overall process efficiency.

Streamlined Setup and Fixturing: By reducing the reliance on elaborate fixturing and setup arrangements, 11-axis machining simplifies the preparation process for part finishing. The increased range of motion allows for more flexible workholding solutions, optimizing workflow and reducing setup time and associated costs.

Enhanced Productivity and Cost Efficiency: The precision and efficiency afforded by 11-axis machining translate into tangible benefits for manufacturers. By minimizing material waste, improving cycle times, and reducing the need for secondary operations, this technology streamlines production workflows and enhances overall productivity while maintaining competitive pricing.

The Future of Machining

In the pursuit of precision manufacturing, the transition from 5-axis to Multi Axis machining represents a significant leap forward. By unlocking new levels of versatility, accuracy, and efficiency in part finishing processes, Multi-Axis machining empowers manufacturers to push the boundaries of innovation and meet the exacting demands of modern industries. As this technology continues to evolve, its transformative impact on precision manufacturing will undoubtedly shape the future of the industry, driving advancements in product quality, performance, and competitiveness.

Contact James Engineering on how multi-axis machining can improve your cnc manufacturing process. Sales@James-Engineering.com

Deburring for Different Industries: Custom Solutions for Unique Needs

Different industries have unique deburring requirements based on the materials they work with, the specific applications of their products, and the desired quality standards. As such, custom deburring solutions tailored to each industry's needs are essential for achieving optimal results. Let's explore how deburring is applied in various industries and the importance of custom solutions.

Deburring is a critical process in manufacturing that involves the removal of burrs, sharp edges, and other imperfections from metal, plastic, wood, and other materials. These imperfections can arise during machining, casting, forging, or other fabrication processes. Deburring not only enhances the aesthetics of the final product but also ensures safety and functionality by eliminating potential hazards and improving surface quality.

Different industries have unique deburring requirements based on the materials they work with, the specific applications of their products, and the desired quality standards. As such, custom deburring solutions tailored to each industry's needs are essential for achieving optimal results. Let's explore how deburring is applied in various industries and the importance of custom solutions.

The importance of precise chamfer lies in its ability to enhance the structural integrity and aesthetic appeal of engineered components, ensuring seamless assembly and optimal functionality in various applications.

Automotive Industry

Automotive Industry has varied components such as engine parts, transmission components, chassis components, and body panels that require deburring or chamfering

In the automotive industry, deburring plays a crucial role in ensuring the quality and performance of components such as engine parts, transmission components, chassis components, and body panels. Burrs left on these parts can interfere with proper assembly, cause premature wear, and compromise safety.

Custom deburring solutions for the automotive industry often involve automated processes such as multi axis systems equipped with specialized tools for consistent and efficient burr removal. Additionally, industry-specific chamfer or radius techniques, for complex-shaped parts or bulk processing of small components, are employed to meet the industry's stringent quality standards.

Deburring complex aerostructure parts poses unique challenges due to their intricate designs and critical role in aerospace applications. Our advanced solutions address these complexities, ensuring thorough and precise deburring for enhanced performance and safety in aircraft manufacturing.

Aerospace Industry

The aerospace industry demands the highest precision and reliability in its components to ensure the safety of aircraft and spacecraft. Deburring is critical in aerospace manufacturing to eliminate any surface imperfections that could compromise aerodynamics, structural integrity, or functionality.

Custom deburring solutions for the aerospace industry often incorporate advanced Focused Deburring technologies for intricate and delicate parts like turbine blades, airfoils, and engine components. These techniques enable precise edge and surface finishing without compromising the dimensional accuracy or material properties of the parts.

Medical device finishing plays a crucial role in ensuring the safety, functionality, and regulatory compliance of medical equipment, encompassing processes such as polishing, washing, deburring, and radius machining.

Medical Device Manufacturing

In the medical device manufacturing industry, where precision, cleanliness, and biocompatibility are paramount, deburring plays a vital role in ensuring the safety and effectiveness of medical implants, surgical instruments, and diagnostic equipment.

Custom deburring solutions for medical device manufacturing often involve specialized 11 axis and multiple tools to achieve smooth, clean surfaces free of burrs and contaminants.

Delving into micron-level deburring is pivotal in both medical device manufacturing and aerospace engineering. This precision process guarantees smooth surfaces and optimal functionality in medical parts, while also enhancing the performance and reliability of intricate aerospace components for seamless operation in challenging environments.

Micron Industry

In precision-focused industries, deburring is crucial for ensuring the functionality and reliability of components requiring micron-level precision. Custom deburring solutions often employ precise techniques and specialized equipment with programmable controls to meet exacting standards for product quality and performance.

Deburring is an essential process in manufacturing, serving diverse industries including automotive, aerospace, medical devices, electronics, and more. Customized deburring solutions tailored to each industry's needs are crucial for achieving top-quality results.

By investing in industry-specific deburring solutions, manufacturers ensure product integrity, reliability, and safety while meeting industry standards.

To learn how automated deburring and chamfering can work for your industry, contact The Deburring Experts at Sales@James-Engineering.com

How Automated Deburring Systems Revolutionize Manufacturing

In manufacturing, efficiency and precision are paramount. Any process that can streamline production while maintaining quality is highly sought after. One such innovation making waves in the manufacturing industry is automated deburring systems. These systems, including automated deburring machines and automated chamfer machines, are revolutionizing the way manufacturers handle post-processing tasks. Let's dive into what these systems are, how they work, and the benefits they offer.

In manufacturing, efficiency and precision are paramount. Any process that can streamline production while maintaining quality is highly sought after. One such innovation making waves in the manufacturing industry is automated deburring systems. These systems, including both automated deburring machines and automated chamfer machines, are revolutionizing the way manufacturers handle post-processing tasks. Let's dive into what these systems are, how they work, and the benefits they offer.

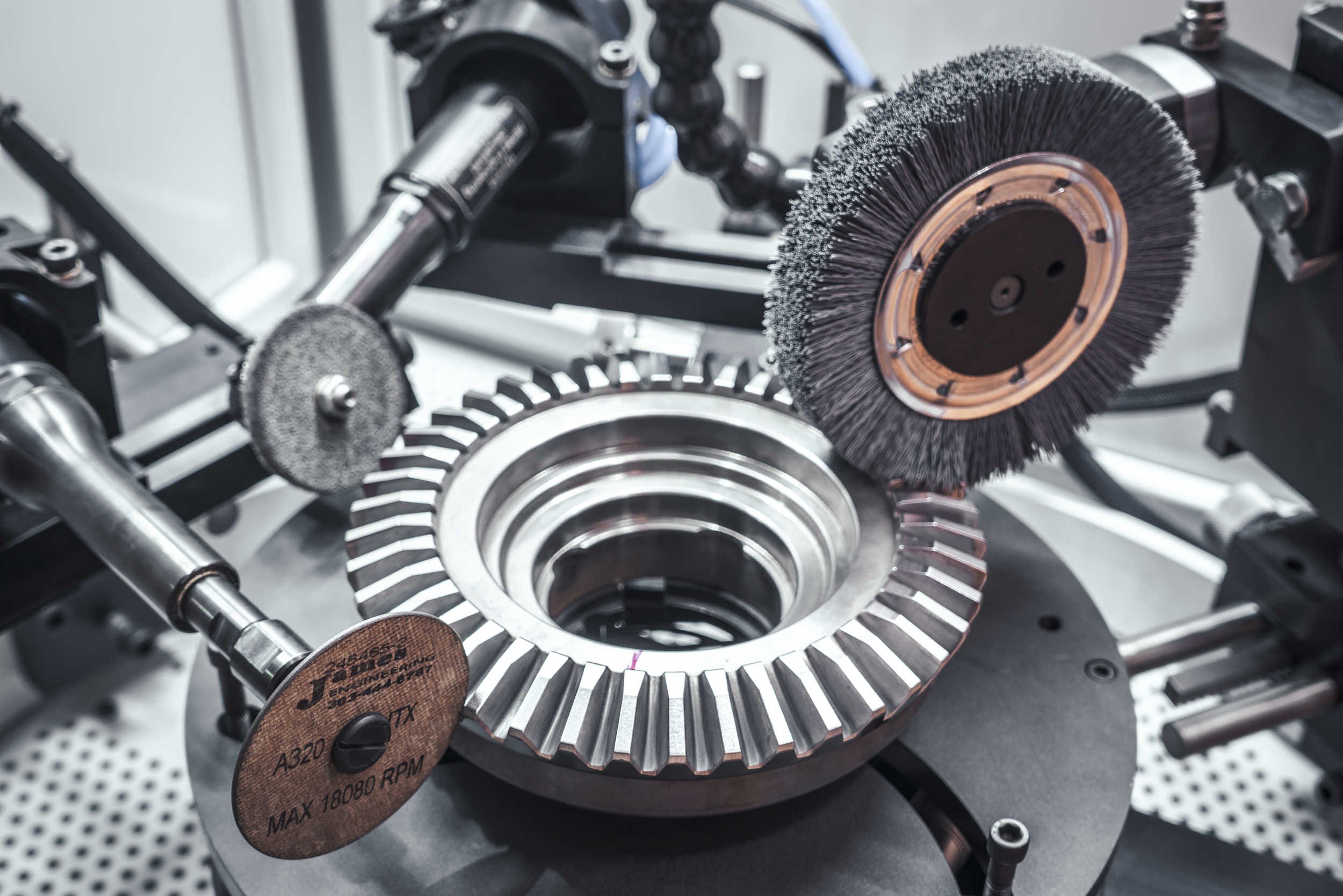

Spiral Bevel Gear from an attack helicopter. This is a life critical part. Before we were introduced to the client; they were having component failures; the teeth were breaking from stress risers around the tooth. After we chamfered and brushed all the features on the part, the failures were eliminated. James Engineering Photo

Understanding Automated Deburring Systems

Deburring is a crucial step in manufacturing, particularly in industries like automotive, aerospace, defense and medical device, where precision is non-negotiable. After parts are machined, they often have sharp edges, burrs, or imperfections that need to be removed for safety, functionality, and aesthetics. Traditionally, deburring was a manual or semi-automated process, requiring skilled labor and significant time investment.

Automated deburring systems, on the other hand, utilize advanced technology such as multi-axes, and precision machining techniques like Focused Deburring to automate and streamline the deburring and manufacturing process. These systems are equipped with specialized tools and programing designed to remove burrs, chamfer and radius with unparalleled accuracy and efficiency.

The Role of Automated Deburring Machines

Automated deburring machines are at the forefront of this technological revolution. They come in various configurations, and with multiple finishing tools. CNC (Computer Numerical Control) machines with deburring capabilities simply can’t deburr, chamfer, radius or polish at the high precision level as dedicated systems. Specialized machines work by precisely targeting and removing burrs from machined parts, then completing the process by chamfering, polishing and washing parts shortening the overall process.

They can handle a wide range of materials, from metals like aluminum and steel to plastics and composites, or soft metals such as die casted or powdered metals, making them versatile across industries. By integrating dedicated finishing systems into production lines, manufacturers can significantly reduce cycle times, improve consistency, and enhance overall product quality.

Twin tower, 5 Axis MAX System with 2 position pallet changer by James Engineering

Advantages of Automated Chamfer Machines

In addition to deburring, chamfering is another essential post-processing step in manufacturing. Chamfering involves creating beveled edges or angles on the edges of parts, enhancing their durability, aesthetics, and functionality. Automated chamfer machines complement automated deburring systems by efficiently performing this task.

These machines utilize precision cutting tools to create uniform chamfers on machined parts. By automating chamfering, manufacturers can achieve consistent results across large production runs, eliminate human error, and reduce the risk of injuries associated with manual chamfering methods.

Diagram showing chamfered angle

Bevel versus Chamfer

Optimizing Manufacturing with Automated Systems

The integration of automated deburring and chamfering systems into manufacturing processes offers several key advantages:

Increased Efficiency: By automating time-consuming deburring and chamfering tasks, manufacturers can significantly reduce production cycle times, leading to higher throughput and improved overall efficiency.

Enhanced Quality: Automated systems ensure consistent and precise deburring and chamfering, resulting in higher-quality finished parts with fewer defects or inconsistencies.

Cost Savings: While the initial investment in automated systems may be higher, the long-term cost savings from reduced labor costs, increased productivity, and minimized rework make them a cost-effective solution for manufacturers.

Improved Safety: By minimizing the need for manual intervention in deburring and chamfering processes, automated systems contribute to a safer working environment for manufacturing personnel.

In this manufacturing flow, OEM James Engineering creates specialized machinery designed for tasks like gear fabrication. Ontario Gear & Drive utilizes this machinery to manufacture precision gears, which serve as critical components in various mechanical systems, including vehicles. These gears are then integrated into the manufacturing process of companies like Argo, completing the supply chain from machinery production to the assembly of end products such as vehicles.

Automated deburring and chamfering systems are transforming the manufacturing landscape, offering unparalleled efficiency, precision, and cost savings. By leveraging the latest advancements in automation and machining technology, manufacturers can streamline their production processes and stay ahead of the competition.

As industries continue to evolve, embracing automation and investing in advanced manufacturing technologies like automated deburring systems will be essential for maintaining a competitive edge in today's fast-paced market.

Learn more about various deburring and chamfering systems here.

CASE STUDY: Manufacturing Customer Survey Finds The Following Results

In 2011, we conducted a client survey of over 1500 manufacturers, across varied industries doing manual and hand deburring.

How Much Production Time Are You Losing?

Set up? Processing Time? The MAX speeds all of this!

FASTEST CHANGE OUTS:

This doesn’t even include the faster processing time of each part... If you deburr 250 parts a month, you could save approximately 120 hours in setup time alone.

How much production time are you losing?

Set up? Processing Time? The MAX speeds all of this!

Once a setup is made, it is saved as a recipe.

Recipes are called up by filename instantly.

No Changeover or setups!

*As an option, we also offer auto-part ID.

Lower your Cost Per Part!

The MAX Systems are ideal for applications where parts are run on a repeat basis. The frequency and

volume is not important. In other words, you can run a different part every single cycle as long as

the parts are re-run at some point; even if it is five years down the road. Your saving yourself time and money!

Fastest Cycle Times in the Biz!

Run a different part every cycle!

Automatic Wheel Wear Compensation

Chamfer, Radius or any other type of edge finish

It has been about five years since we bought your deburring machine. I can boast that we have greatly improved the quality of gears as opposed to hand deburring. The productivity is unmatched! Many of the parts used to take 30 minutes by hand and now the same part is done in about 30 sec.

— Ramdas Amin, Mfg Engineer, GE Aviation Systems

I have been using a James Engineering 462 for about 4 years now. It works wonderful I can’t imagine working without that machine. It has done our company justice!

— Tim Fuller, Manufacturing Engineer, Baldor

We have benefited from faster set-up times to faster cycle times. The machine has functioned effectively without failure ever since we powered it up in 2005.

It is extremely easy to set up on spiral bevel ring gears and many other parts we manufacture.

We highly recommend it for any company interested in improving their deburring processes

— Paul Campion, GM, Reliance Gear

See more of our customers here.

Achieving Precision: Advancing Defense Industry Standards With Precision Techniques

In aerospace and defense manufacturing, achieving unprecedented precision is not merely a goal but a necessity. Every component must adhere to exacting standards to ensure uncompromised safety and performance. In this article, we delve into the realm of advanced deburring and chamfering technologies, particularly focusing on high tech, cutting-edge, 11-axis systems. We'll uncover how this system, with its meticulous attention to detail and micrometer-level precision, redefines part finishing in the defense industry, setting new benchmarks for excellence.

In aerospace and defense manufacturing, achieving unprecedented precision is not merely a goal but a necessity. Every component must adhere to exacting standards to ensure uncompromised safety and performance. In this article, we delve into the realm of advanced deburring and chamfering technologies, particularly focusing on high tech, cutting-edge, 11-axis systems. We'll uncover how this system, with its meticulous attention to detail and micrometer-level precision, redefines part finishing in the defense industry, setting new benchmarks for excellence.

The Significance of Deburring and Part Finishing:

Deburring and part finishing stand as crucial processes in the manufacturing chain, particularly within the defense and medical sectors, where precision is paramount. A single burr or imperfection in a machined component can have far-reaching consequences, jeopardizing not only the integrity of the individual part but also the overall system's performance and reliability. Thus, meticulous attention to detail and precision in deburring and finishing processes is non-negotiable.

Understanding Microns and Their Role in Precision Machining:

Microns, or micrometers, represent a unit of measurement equivalent to one-millionth of a meter. In the realm of precision machining, particularly in industries such as defense and medical where tolerances are exceptionally tight, microns serve as the yardstick for evaluating precision and accuracy. Achieving part dimensions and surface finishes within micrometer tolerances is imperative to ensure optimal functionality, reliability, and safety of machined components.

Nuclear Tomahawk Cruise Missile manufactured by Hughes & Raytheon

11-Axis Machining: Unveiling the Technological Marvel

At the forefront of precision machining technology lies James Engineering's revolutionary 11-axis deburring and chamfering system, The MAX™. Unlike conventional deburring methods that often rely on manual labor and are susceptible to inconsistencies, this state-of-the-art system integrates advanced automation with unparalleled precision, delivering results that set the industry standards. Semi to fully automated.

Key Technological Features:

Multi-Axis Flexibility:

With 11 axes of movement, The MAX™ System boasts unparalleled adaptability, accommodating a diverse range of part geometries and sizes. This versatility ensures thorough and precise deburring and chamfering even on the most intricate components, eliminating the limitations associated with traditional deburring methods.

Micrometer-Level Precision:

Leveraging cutting-edge synchronized motion control technology, The MAX System™ operates with precision in microns as well as patented Focused Deburring™. This level of accuracy ensures that deburring and chamfering processes are executed with meticulous attention to detail, meeting or exceeding the stringent tolerances required in defense and medical applications.

Automated Efficiency:

Automation is seamlessly integrated into every facet of MAX's system, streamlining processes and minimizing the risk of human error. By eliminating manual intervention, the system ensures consistent and uniform finishing across all parts, enhancing efficiency without compromising precision.

Eliminate error and scrap

Surface Quality Optimization:

Through advanced polishing and grinding capabilities, James Engineering's technology achieves impeccable surface finishes, characterized by smoothness and uniformity that meet the exacting standards of the aerospace and defense as well as medical industry specifications. This superior surface quality not only enhances aesthetics but also contributes to the longevity and performance of machined components.

Experience a James Edge

Enhanced Productivity:

The MAX’s 11-axis system is designed to maximize productivity without sacrificing precision or quality. By reducing cycle times and increasing throughput, the system optimizes manufacturing processes, thereby enhancing overall productivity and profitability for cost conscious defense industry manufacturers.

Elevating Industry Standards: Setting a New Benchmark for Precision Machining

In an era defined by relentless innovation and uncompromising standards, James Engineering's Manual and Automated 11-axis deburring and chamfering Systems emerge as a beacon of excellence in precision machining. By exceeding industry standards and delivering micrometer-level precision, this groundbreaking technology revolutionizes part finishing in the defense and medical sectors, setting new benchmarks for quality, reliability, and performance.

As the demand for precision components continues to escalate within the defense and medical industries, the significance of advanced deburring and part finishing technologies cannot be overstated.

James Engineering's 11 Axis Finishing Systems -manual to fully automated, The MAX™ boasts unmatched precision, and poised to revolutionize the landscape of precision machining. Designed to meet the demands of life-critical parts within the defense and medial industry, this advanced technology has already been adopted by industry giants. By using Focused Deburring™ manufacturers not only ensure compliance with stringent government and industry standards but also pave the way for a future characterized by unparalleled precision, reliability, and innovation in critical component manufacturing.

To watch the MAX in action, check out the James Engineering YouTube channel here.

To contact James Engineering about custom deburring and chamfering systems, call at (303) 444-6787 or email Sales@James-Engineering.com

Maximizing Efficiency: How Automated Deburring Systems Revolutionize Manufacturing

In the fast-paced world of modern manufacturing, the quest for efficiency is relentless. Every step in the production process must be optimized to meet the demands of precision, speed, and cost-effectiveness. One area where significant strides have been made is in the realm of deburring, and the introduction of automated deburring systems has revolutionized the manufacturing landscape. This article delves into the transformative impact of automated deburring, exploring its benefits, applications, and how it has become a cornerstone for maximizing efficiency in diverse industries.

In the fast-paced world of modern manufacturing, the quest for efficiency is relentless. Every step in the production process must be optimized to meet the demands of precision, speed, and cost-effectiveness. One area where significant strides have been made is in the realm of deburring, and the introduction of automated deburring systems has revolutionized the manufacturing landscape. This article delves into the transformative impact of automated deburring, exploring its benefits, applications, and how it has become a cornerstone for maximizing efficiency in diverse industries.

The Evolution of Deburring:

Deburring, once a manual and time-consuming process, has undergone a remarkable evolution with the integration of automation. Traditionally, workers meticulously removed burrs and sharp edges from machined components, a task that was not only labor-intensive but also prone to variations in quality. Automated deburring systems have emerged as a game-changer, offering a streamlined and consistent approach to this crucial manufacturing step.

Benefits of Automated Deburring Systems:

Precision and Consistency:

Automated deburring systems provide unparalleled precision, ensuring that every component is treated with the same level of accuracy. This consistency is vital in industries where even the slightest deviation from specifications can lead to performance issues or product defects.

Time Efficiency:

Time is of the essence in manufacturing, and automated deburring significantly reduces cycle times. The swift and continuous operation of robotic systems allows for a faster throughput of components, contributing to overall production efficiency.

Labor Cost Savings:

The automation of deburring processes translates into reduced labor costs. Manufacturers can reallocate human resources to more intricate tasks, while automated systems handle the repetitive and time-intensive nature of deburring.

Enhanced Safety:

Manual deburring poses risks to workers due to sharp edges and repetitive motion injuries. Automated systems eliminate these safety concerns, creating a safer working environment and reducing the likelihood of workplace accidents.

Applications Across Industries:

Automated deburring systems find applications in a myriad of industries, from aerospace and automotive to electronics and medical device manufacturing. The versatility of these systems allows them to adapt to various materials, geometries, and part sizes, making them an invaluable asset in diverse production environments.

Technological Advancements:

The 11-Axis MAX system has further enhanced the capabilities of automated deburring systems, taking them next level. Intelligent and easy to use, these systems adapt to different materials and geometries, optimizing the deburring process for each unique component.

Case Studies:

Several manufacturing leaders have reported substantial improvements in efficiency, quality, and cost savings after implementing automated deburring systems. Real-world examples showcase how these systems have become a cornerstone of lean manufacturing practices, driving competitiveness in the global market.

The integration of automated deburring systems represents a transformative leap forward in manufacturing efficiency. As industries continue to push the boundaries of innovation, automated deburring emerges as a key player, ensuring that components meet stringent quality standards while optimizing production processes. Manufacturers embracing these advanced systems are not just keeping pace with the demands of the market; they are setting new standards for efficiency and reliability in the modern era of manufacturing.

To learn more about what all the MAX has to offer, email us or call us at (303) 444-6787

Deburring and Part Finishing in the Aerospace Sector: Exceeding Industry Standards

In the dynamic world of aerospace engineering, precision and quality are paramount. Every component, no matter how small, plays a crucial role in the overall performance and safety of an aircraft. One often overlooked but essential process in aerospace manufacturing is deburring and part finishing. This article explores the significance of deburring, its role in meeting industry standards, and the latest techniques employed by top engineers in the aerospace sector.

In the dynamic world of aerospace engineering, precision and quality are paramount. Every component, no matter how small, plays a crucial role in the overall performance and safety of an aircraft. One often overlooked but essential process in aerospace manufacturing is deburring and part finishing. This article explores the significance of deburring, its role in meeting industry standards, and the latest techniques employed by top engineers in the aerospace sector.

Apache Longbow manufactured by Boeing

Understanding Deburring:

Deburring is the process of removing unwanted rough edges, burrs, or imperfections from machined or manufactured parts. In aerospace, where precision is non-negotiable, deburring ensures that components fit seamlessly together, reducing the risk of mechanical failure and enhancing overall efficiency.

Importance in Aerospace Manufacturing:

Aerospace components undergo intricate machining processes, leaving behind sharp edges and burrs. These imperfections can compromise the structural integrity of the parts and, consequently, the entire aircraft. Deburring is not merely a cosmetic enhancement; it is a critical step in maintaining the safety and reliability of aerospace systems.

Industry Standards:

The aerospace industry adheres to rigorous standards and regulations to ensure the highest level of safety and performance. Deburring plays a pivotal role in meeting these standards, as components must not only meet precise dimensional specifications but also undergo thorough inspection to eliminate any defects that could compromise the integrity of the final product.

an aerospace finish does not allow for any

grinding marks

surface blemishing

surface scratches

any jagged edges

inconsistencies and so on.

since most parts are “life critical”,

THE AEROSPACE INDUSTRY demands perfection.

F-22 Raptor Lockheed Martin/Boeing

Latest Techniques in Aerospace Deburring:

As technology advances, so do the techniques employed in aerospace deburring. Top aerospace and defense producers now utilize state-of-the-art equipment, such as The MAX, an 11-axis multi-finishing system that offers unparalleled accuracy, consistency, and speed in finishing processes. The use of the patented Focused Deburring, ensures that even the most intricate components can be deburred with precision, meeting the stringent requirements of aerospace applications. While also contributing to increased efficiency and cost-effectiveness in the overall manufacturing process.

THE MAX

11-Axis Advanced Multi-Finishing System

Equipped with up to 4 different precision finishing tools has revolutionized the aerospace and defense industry.

In the demanding field of aerospace engineering, every detail matters. Deburring and part finishing are essential steps in ensuring the integrity, safety, and performance of aerospace components. As technology continues to evolve, top manufacturers will continue to embrace innovative solutions to meet and exceed industry standards. The combination of precision, automation, and advanced methods propels aerospace manufacturing into a future where safety and quality are never compromised.

To learn more about The MAX click here.

If you’re interested in learning how to improve your own finishing process, give James Engineering a call at (303) 444-6787, or email us at Sales@James-Engineering.com.

Mastering Precision: A Comprehensive Guide to Overcoming Part Finishing Challenges

In the intricate realm of manufacturing, achieving precision in part finishing is an ongoing pursuit that directly influences the quality and functionality of the final product. This comprehensive guide explores the common challenges encountered in part finishing and offers valuable insights into overcoming these hurdles with the help of advanced deburring and chamfering machines.

In the intricate realm of manufacturing, achieving precision in part finishing is an ongoing pursuit that directly influences the quality and functionality of the final product. This comprehensive guide explores the common challenges encountered in part finishing and offers valuable insights into overcoming these hurdles with the help of advanced deburring and chamfering machines. Let's embark on a journey to master precision in part finishing.

1. Unwanted Burrs and Sharp Edges

Challenge:

Unwanted burrs and sharp edges can compromise functionality and aesthetics.

Solution: Unwanted burrs and sharp edges can be effectively removed through various methods. Manual tools like files, abrasive brushes, and rotary deburring tools offer precision, while techniques such as abrasive blasting, chemical deburring, and thermal methods provide automated solutions. Advanced approaches like electrochemical deburring, cryogenic methods, waterjet cutting, and laser deburring cater to specific needs, emphasizing the importance of selecting the most suitable method based on material, part complexity, and production requirements.

Additional Insights:

2. Inconsistent Surface Finish:

Challenge:

Achieving a consistent surface finish is crucial for quality standards.

Solution: Achieving a consistent surface finish is crucial for quality standards because it directly impacts the appearance, functionality, and performance of a finished product. Consistency ensures uniformity in texture and appearance, which is especially important in industries where aesthetics matter, such as automotive, aerospace, or consumer electronics. Additionally, a consistent surface finish is indicative of precision and attention to detail in manufacturing processes, reflecting a higher level of quality and meeting the stringent standards expected by customers and industry regulations. In applications where friction, wear, or corrosion resistance are critical factors, a uniform surface finish is essential for optimal performance and longevity of the final product. Overall, consistency in surface finish contributes to the reliability, durability, and overall quality of the manufactured components or products.

Additional Insights:

Multi-axis deburring and chamfering machines, like the 11-Axis MAX provide control for a uniform finish, meeting specifications.

Large Batch Consistency: Guarantees uniformity even in high-volume production.

As well as the flexibility to run one off pieces.

3. Material Compatibility:

Challenge:

Diverse materials require tailored approaches for consistency.

Solution: Versatile machines handle various materials, ensuring adaptability and consistent finishing.

additional insights

Material-Specific Challenges: The MAX addresses material-specific intricacies.

Transitioning Between Materials: Seamless adaptation minimizes downtime during material shifts.

4. Complex Geometries:

Challenge

Achieving uniform finishing in intricate geometries is challenging.

Solution: Advanced machines with multi-axis capabilities navigate complex shapes with precision.

additional insights

Features: The MAX’s 11-AXIS accesses intricate internal spaces efficiently unlike anything on the market.

Variable Thickness Challenges: Precision extends to variable thicknesses, overcoming challenges associated with varying thicknesses within a single part.

No Masking: Our patented Focused Deburring saves time with precision, never mask another part.

5. Efficiency and Speed: