Grinding Wheels

Experience the Difference

High Precision Grinding Wheels

Manufactured for James Engineering, only from the experts at Rex-Cut Abrasive!

We are pleased to announce that we are a Rex-Cut Abrasive distributor. Rex-Cut has many quality distributors. What sets James Engineering apart from the rest is the following:

We are a stocking distributor. We carry hundreds of wheels in stock at all times!

Our prices are some of the best on the market. Why? Because we are a deburring machine manufacturer first and foremost. Rexcut simply helps our machines shine even brighter with their high-quality products.

We inspect all wheels by hand. This allows us to ensure that wheel thickness is closely monitored. Rex-Cut’s manufacturing process is better than anyone else in our opinion; look for yourselves and see if you don’t agree! Even with Rex-Cut’s excellence, we give Rex-Cut added benefit by sorting the wheels by thickness; in hand deburring, this is not so important, but for companies using deburring machines, this is extremely important.

As one of the leading manufacturers of high-end deburring machines, we worked hand-in-hand with Rex-Cut’s engineering team, constantly developing new products and refining existing products.

This relationship with Rex-Cut Abrasive allows us to maintain our reputation as the best deburring machine manufacturers in the world.

James Engineering’s Rex-Cut Abrasive Grinding Wheels Can Improve Your Deburring Operations - Precision, Durability, and Consistency in Action!

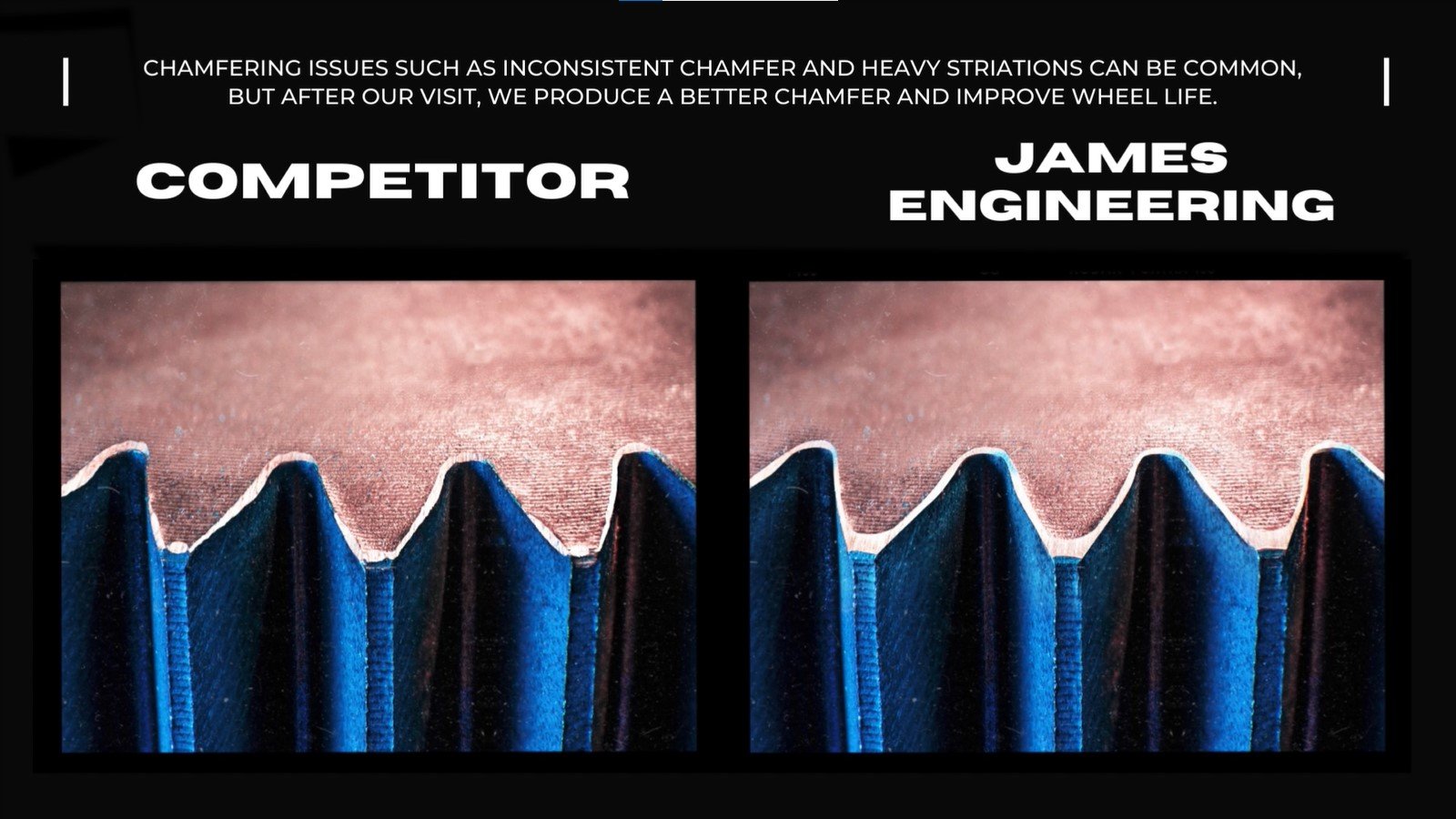

The right Gear grinding wheel can make the difference

Our abrasive grinding wheels are meticulously customized for us by the experts at Rex-cut Abrasives to achieve precise finishes at tight geometric tolerances. Whether you're working with cutting tools, automotive components like engines or transmissions, or aerospace components, our grinding wheels consistently deliver outstanding results.

The key components of our grinding wheels are the abrasive grains that do the cutting, and the bond that holds the grains together and provides support during cutting. Our wheels are made with a liquid resin which ensures optimal performance over regular powder resin wheels.

Need more information? Don't hesitate to reach out and ask to learn more about our reliable grinding wheels at James Engineering!

Contact us at Sales@James-Engineering.com for a quote today

Woven cloth fiber wheel

- Comprised of cotton, liquid resin, and aluminum oxide

- Cotton acts as a dampener, meaning bounce is drastically reduced

- Clean, precise chamfering

- Unique to James Engineering

woven carbon wheel

- Comprised of carbon fiber and resin

- Produce petite chamfers that are unachievable with any other wheel

- Only sold by James Engineering

WOVEN FIBERGLASS WHEEL

- Homogenous mix of aluminum oxide and resin, and pressed with fiberglass for extra strength

- Time efficient

- Perfect for cutting