Medical Manufacturing finishing

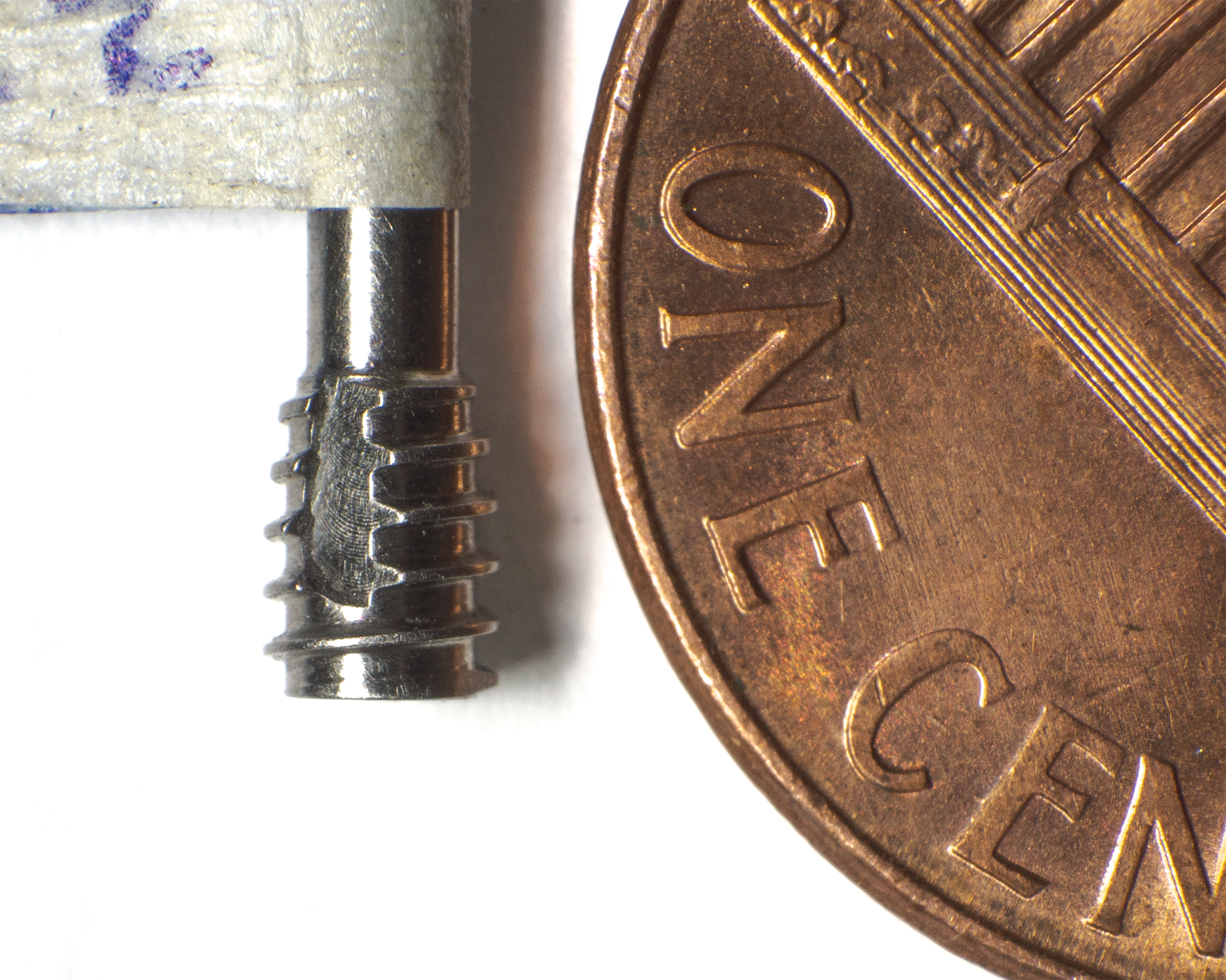

Precision Deburring for Medical Screws: When Microns Matter

Take a look at your hand.

Now imagine a medical screw small enough to fit inside your finger.

Then look closer—down to the threaded tip—about the size of a fruit fly.

At that scale, even the smallest imperfection becomes a serious problem.

The Hidden Risk in Micro Medical Fasteners

During the manufacturing process, tiny metal burrs can be left behind on medical screws—often invisible to the naked eye. On a microscopic level, these burrs are sharp, inconsistent, and unpredictable.

In medical applications, that’s unacceptable.

A single burr can:

Break off and leave metal shards inside the body

Compromise how the screw seats or tightens

Create surfaces where bacteria can collect

Increase the risk of inflammation or life-threatening infection

For components designed to live inside the human body, surface finish isn’t cosmetic—it’s critical.

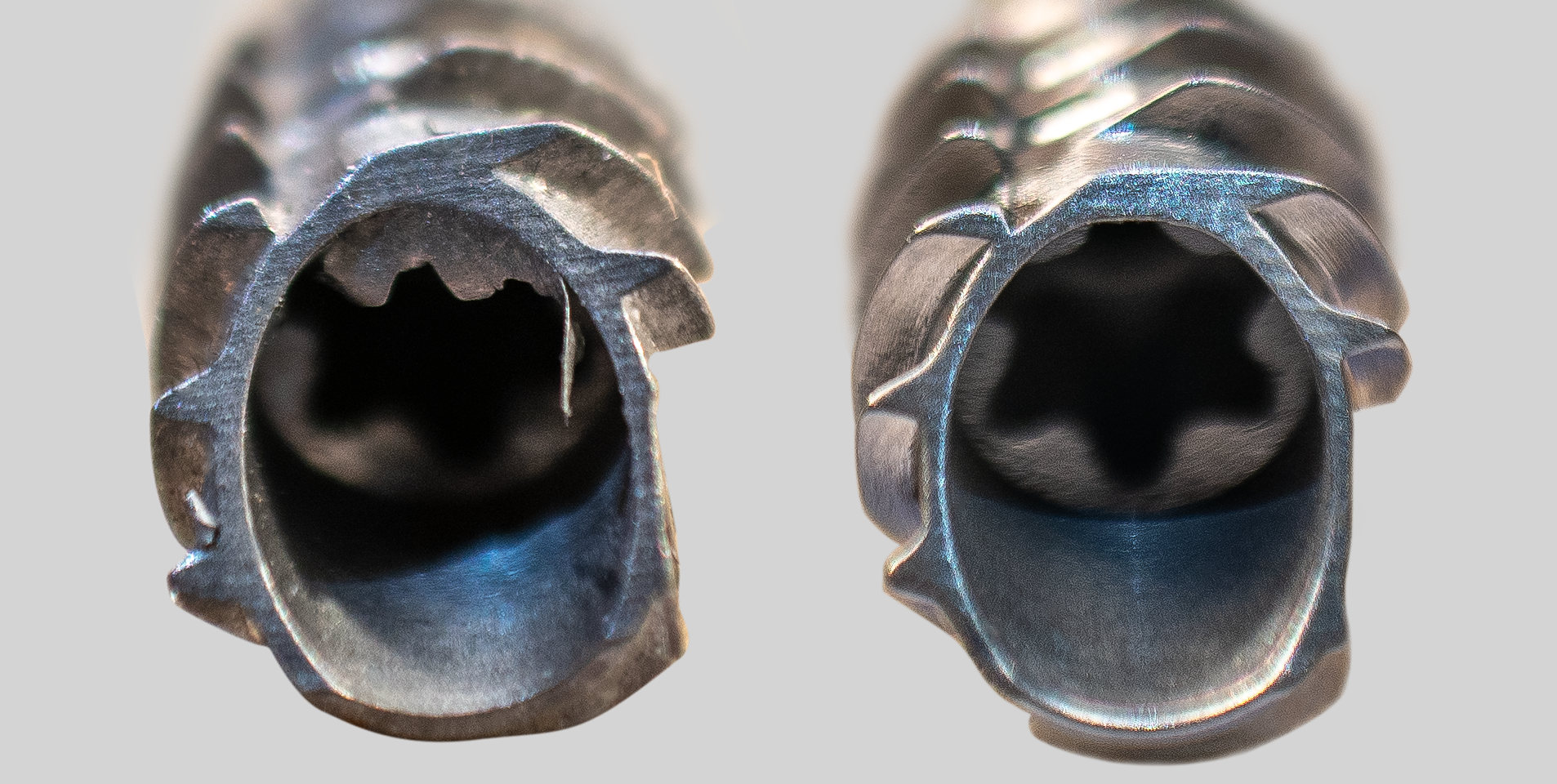

Before and After burr removal

The Challenge: Deburring Without Destroying the Part

Medical screws present a unique finishing challenge:

Extremely small geometry

Fine, delicate threads

Tight tolerance requirements

Zero room for dimensional change

Traditional deburring methods often fall short at this scale. Aggressive processes risk rounding threads, altering dimensions, or introducing inconsistency from part to part.

The goal isn’t just to remove the burr—it’s to do so without touching anything else.

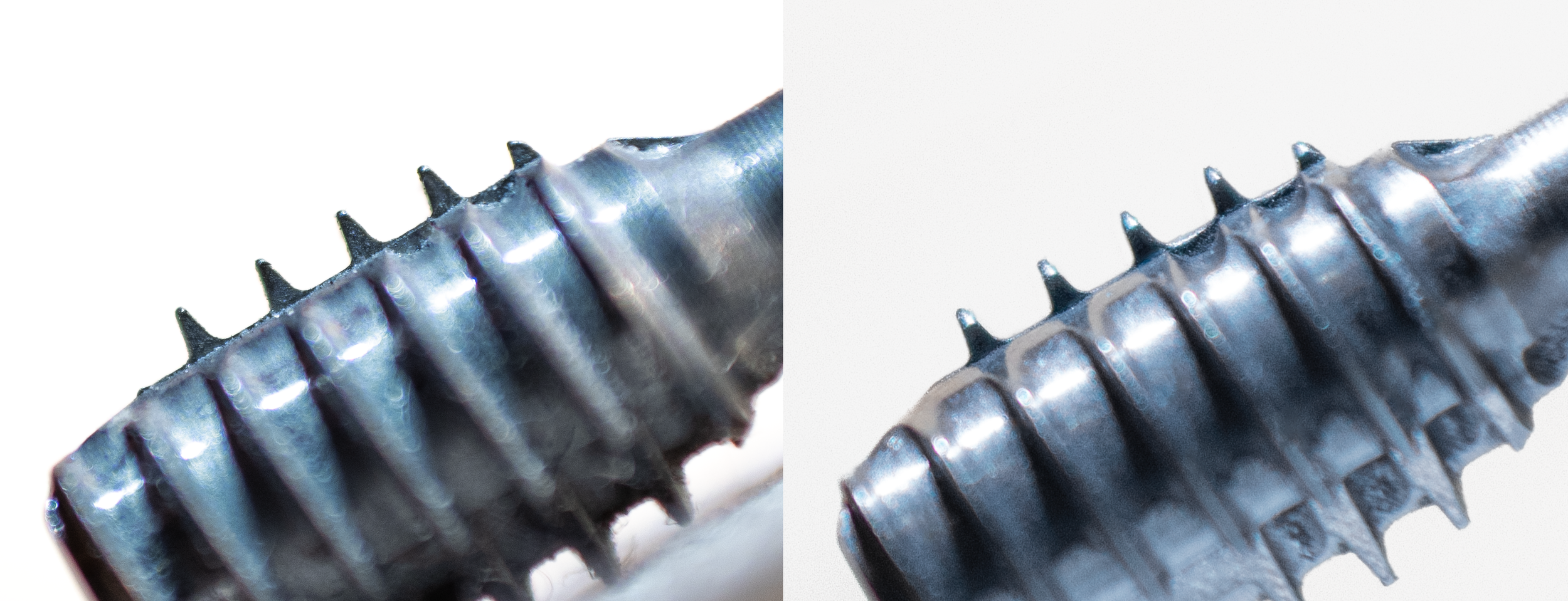

Before and after highlighting the small radius on the edges

Our Solution: Precision Finishing at a Microscopic Level

For this project, we applied a controlled deburring process specifically tuned for micro medical components. The result was a clean, consistent finish across every thread—without damaging the screw’s geometry or function.

The burr was eliminated.

The surface was smoothed.

The integrity of the part was preserved.

This level of precision ensures:

Safer implantation

Reduced risk of contamination

Consistent performance in the field

Compliance with strict medical manufacturing standards

Built for Medical Manufacturing

Whether it’s a tiny medical screw or a complex precision component, the principles stay the same: control, repeatability, and absolute attention to detail.

Our machines are designed to handle:

Ultra-small parts

Complex geometries

Tight tolerances

Scalable production demands

From prototypes to high-volume production, we help medical manufacturers achieve finishes they can trust—because when parts go inside the human body, there’s no margin for error.

Before and after radius on thread edges

Level Up Your Medical Production

No matter the size or complexity of the job, precision finishing makes the difference between acceptable and exceptional.

At James Engineering, we build finishing solutions that meet the demands of the medical industry—where microns matter, consistency is everything, and quality is non-negotiable.

Before and After