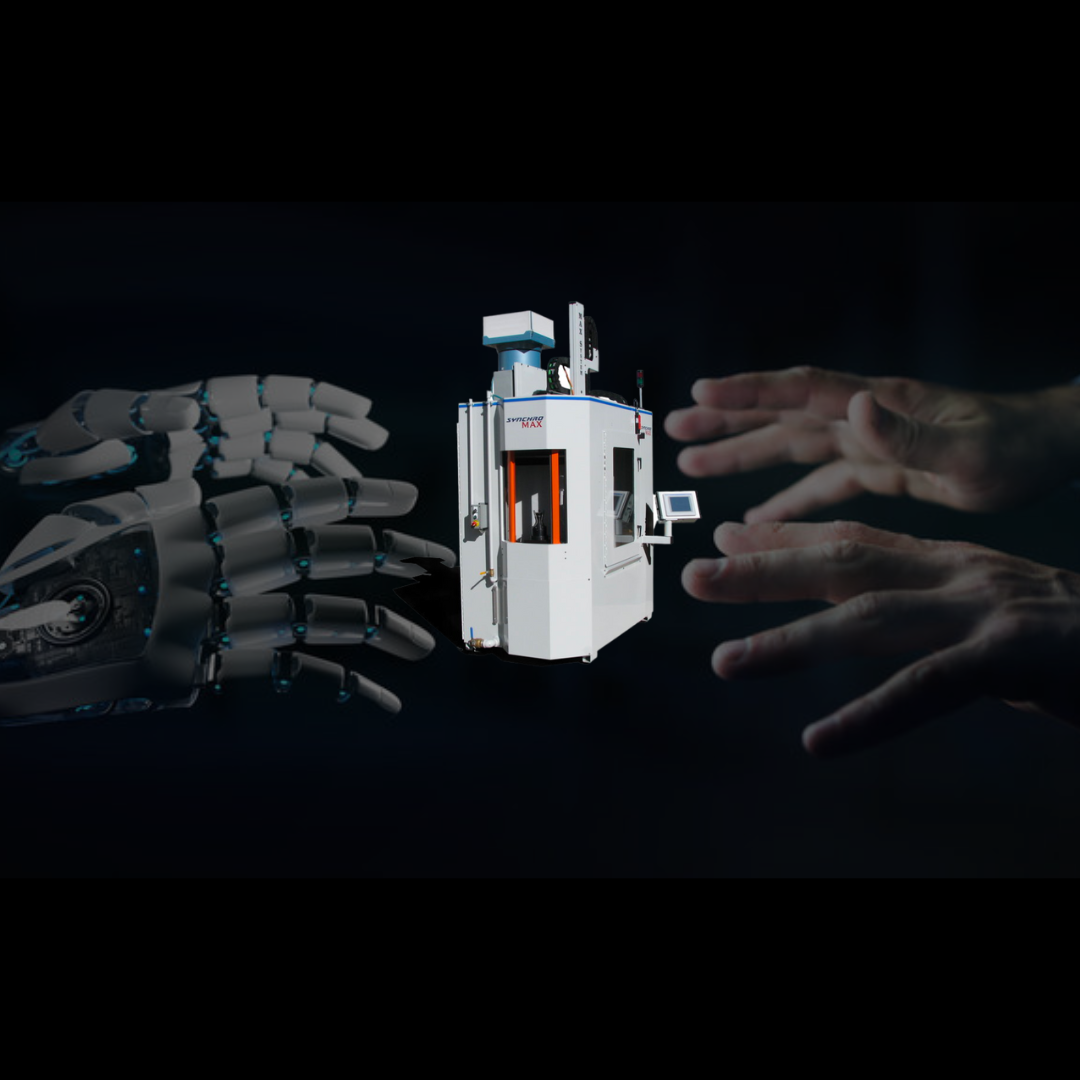

As manufacturing landscapes evolve, automation emerges as a crucial solution for optimizing processes like deburring and chamfering. This article explores the pressing need for automation in manufacturing, the challenges faced by human labor, and the limitations encountered with traditional robotic systems.

The Chamfer Machine Unmatched by All

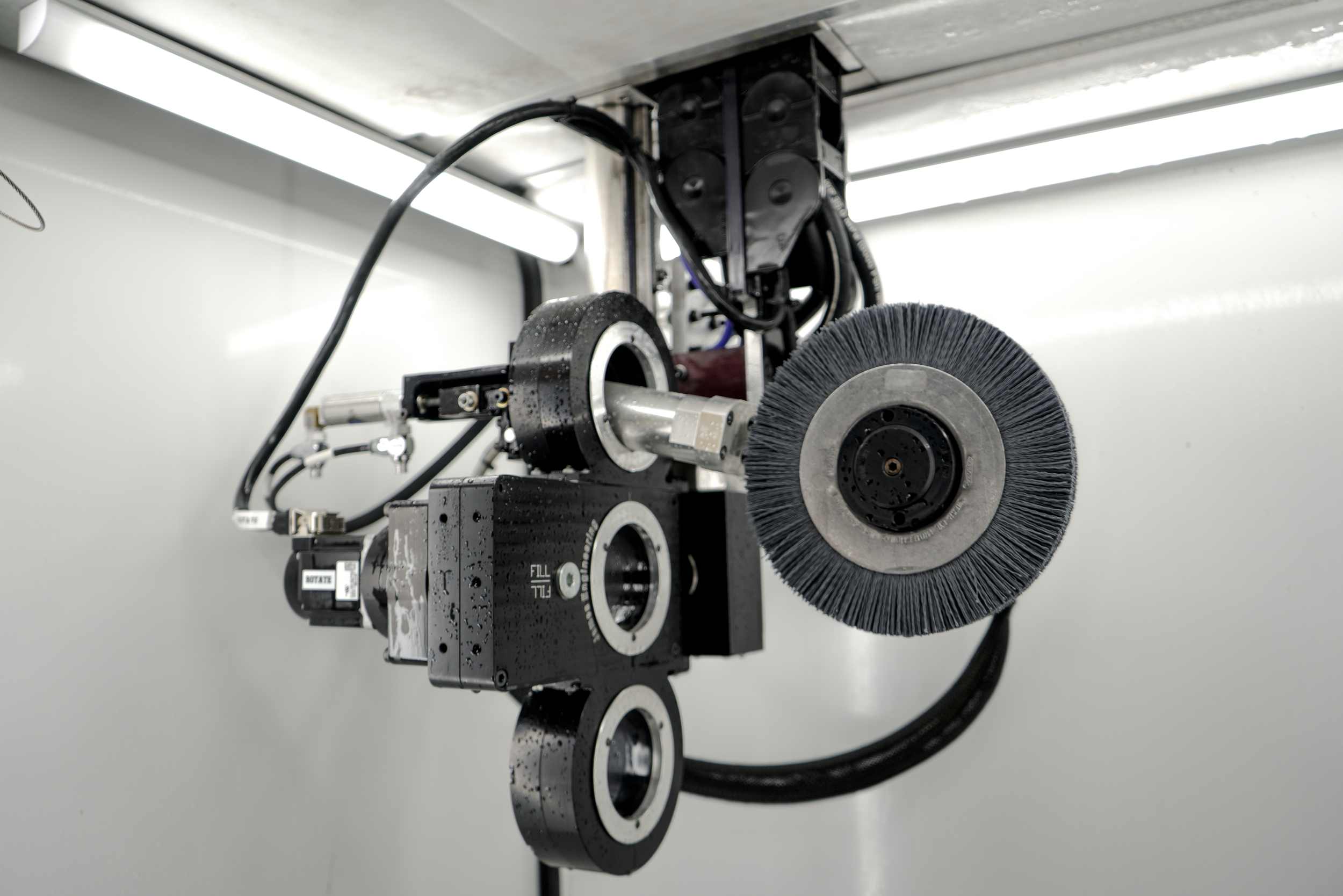

The Power of Compliant Technology, the Magic Behind The MAX

Mastering Work-holding: The Advantages of Self-Centering Clamps

In engineering and manufacturing, achieving precision and efficiency is not just desirable; it's crucial for success. As industries evolve, so do the tools and technologies used to streamline processes and save valuable time. One such innovation that has transformed the landscape of workholding solutions is the self-centering clamp. Let's explore their benefits and understand the uses.

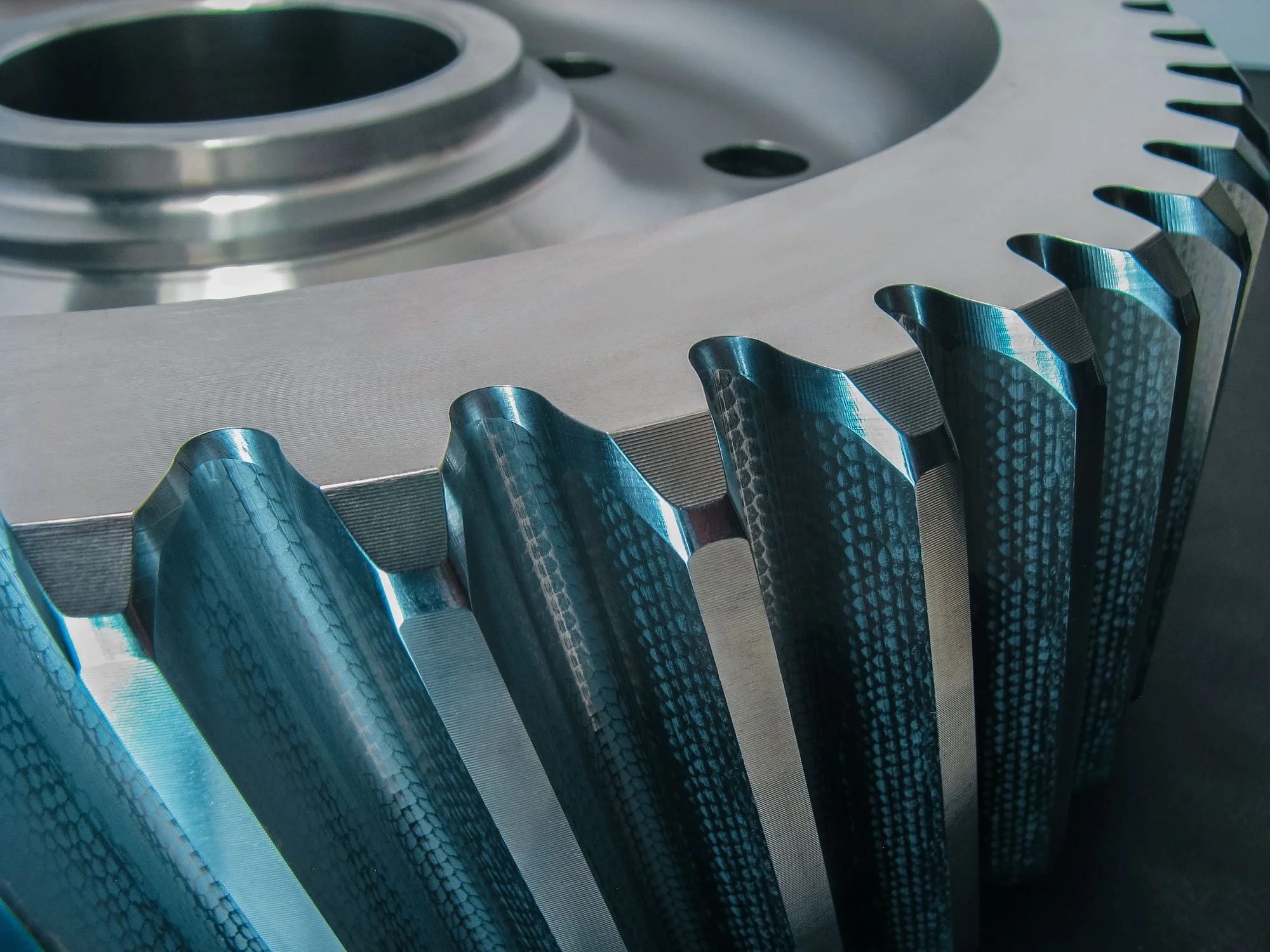

The Largest Gear In The World | Machining's Biggest Debate

In 2009, scientists at the Institute of Materials Research and Engineering, Singapore, created the world's smallest working gear, controlled at a molecular level. This was officiated by the Guinness World Records, but when it comes to the largest gear, there's a bit of controversy. It's a touchy subject in manufacturing circles, with competing firms often reluctant to discuss.

Chamfer Explained - What is the Purpose of a Chamfer?

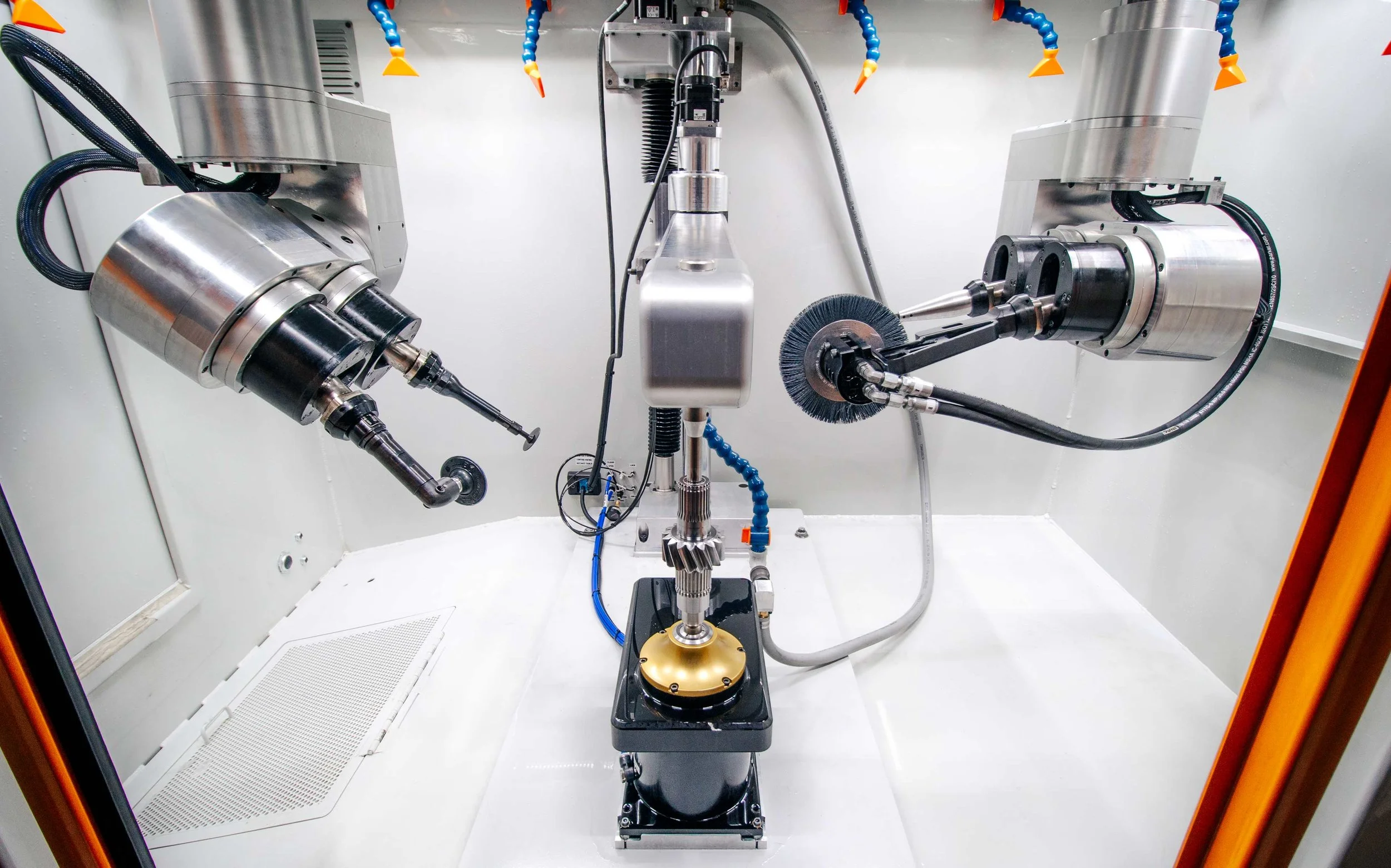

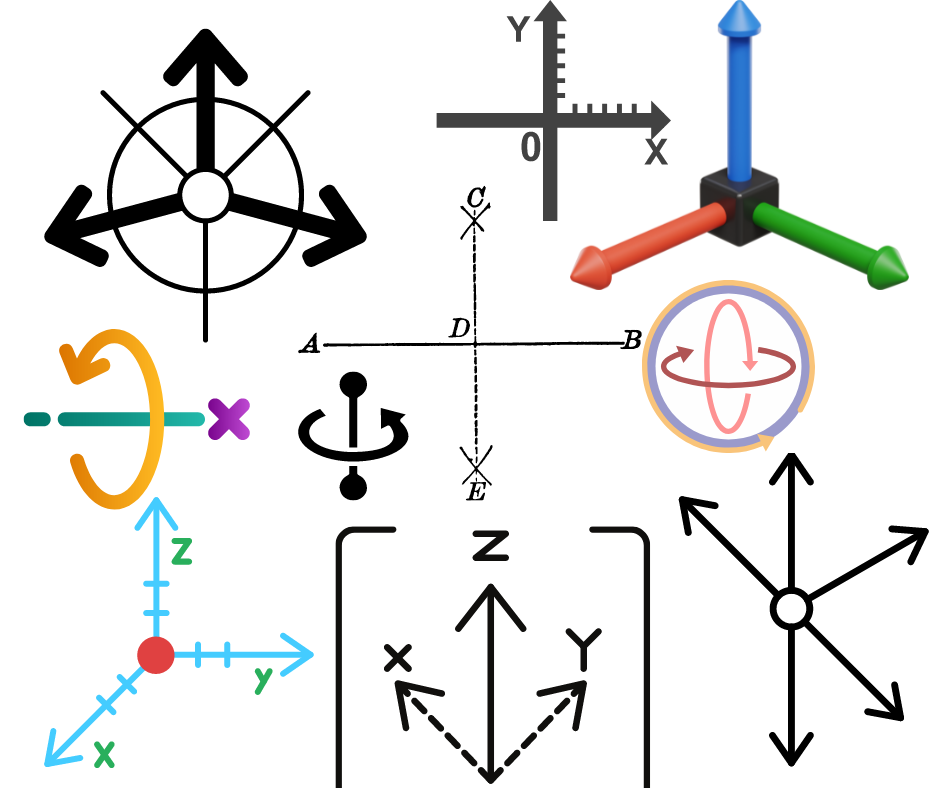

The Advantage of 11-Axis Machining over 5-Axis Machining in High Precision Part Finishing

In the realm of manufacturing, precision is paramount. Achieving high precision in part finishing not only enhances the quality of the final product but also significantly impacts efficiency and cost-effectiveness. Traditional machining methods have paved the way for advanced technologies like 5-axis machining, and now, the evolution continues with the advent of 11-axis machining. In this article, we delve into the nuances of high precision part finishing and explore the distinct advantages offered by 11-axis machining over its 5-axis counterpart.

Deburring for Different Industries: Custom Solutions for Unique Needs

Different industries have unique deburring requirements based on the materials they work with, the specific applications of their products, and the desired quality standards. As such, custom deburring solutions tailored to each industry's needs are essential for achieving optimal results. Let's explore how deburring is applied in various industries and the importance of custom solutions.

How Automated Deburring Systems Revolutionize Manufacturing

In manufacturing, efficiency and precision are paramount. Any process that can streamline production while maintaining quality is highly sought after. One such innovation making waves in the manufacturing industry is automated deburring systems. These systems, including automated deburring machines and automated chamfer machines, are revolutionizing the way manufacturers handle post-processing tasks. Let's dive into what these systems are, how they work, and the benefits they offer.

CASE STUDY: Manufacturing Customer Survey Finds The Following Results

Achieving Precision: Advancing Defense Industry Standards With Precision Techniques

In aerospace and defense manufacturing, achieving unprecedented precision is not merely a goal but a necessity. Every component must adhere to exacting standards to ensure uncompromised safety and performance. In this article, we delve into the realm of advanced deburring and chamfering technologies, particularly focusing on high tech, cutting-edge, 11-axis systems. We'll uncover how this system, with its meticulous attention to detail and micrometer-level precision, redefines part finishing in the defense industry, setting new benchmarks for excellence.

Maximizing Efficiency: How Automated Deburring Systems Revolutionize Manufacturing

In the fast-paced world of modern manufacturing, the quest for efficiency is relentless. Every step in the production process must be optimized to meet the demands of precision, speed, and cost-effectiveness. One area where significant strides have been made is in the realm of deburring, and the introduction of automated deburring systems has revolutionized the manufacturing landscape. This article delves into the transformative impact of automated deburring, exploring its benefits, applications, and how it has become a cornerstone for maximizing efficiency in diverse industries.

Deburring and Part Finishing in the Aerospace Sector: Exceeding Industry Standards

In the dynamic world of aerospace engineering, precision and quality are paramount. Every component, no matter how small, plays a crucial role in the overall performance and safety of an aircraft. One often overlooked but essential process in aerospace manufacturing is deburring and part finishing. This article explores the significance of deburring, its role in meeting industry standards, and the latest techniques employed by top engineers in the aerospace sector.

Mastering Precision: A Comprehensive Guide to Overcoming Part Finishing Challenges

In the intricate realm of manufacturing, achieving precision in part finishing is an ongoing pursuit that directly influences the quality and functionality of the final product. This comprehensive guide explores the common challenges encountered in part finishing and offers valuable insights into overcoming these hurdles with the help of advanced deburring and chamfering machines.