In engineering and manufacturing, achieving precision and efficiency is not just desirable; it's crucial for success. As industries evolve, so do the tools and technologies used to streamline processes and save valuable time. One such innovation that has transformed the landscape of workholding solutions is the self-centering clamp. Let's explore their benefits and understand the uses.

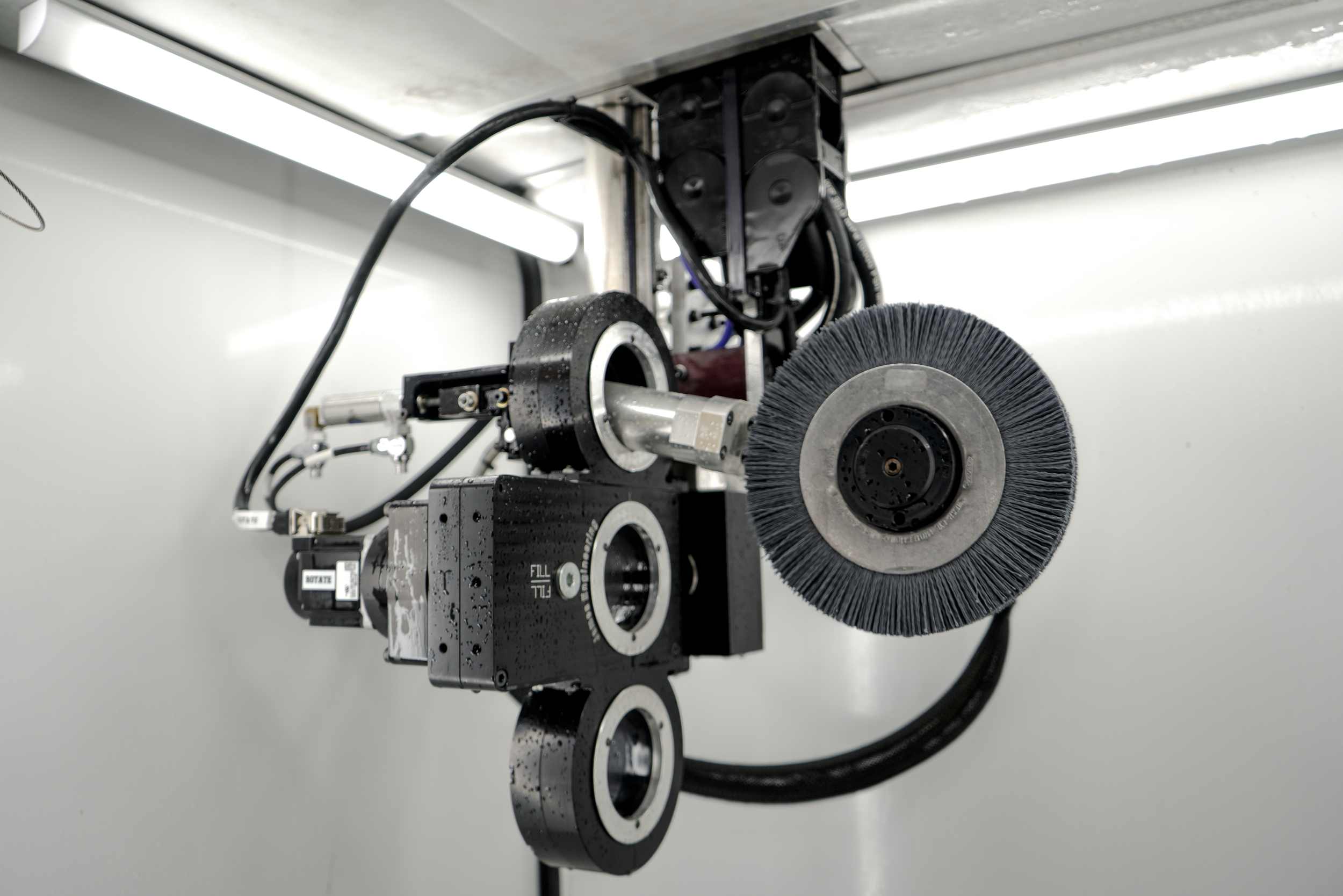

The Advantage of 11-Axis Machining over 5-Axis Machining in High Precision Part Finishing

In the realm of manufacturing, precision is paramount. Achieving high precision in part finishing not only enhances the quality of the final product but also significantly impacts efficiency and cost-effectiveness. Traditional machining methods have paved the way for advanced technologies like 5-axis machining, and now, the evolution continues with the advent of 11-axis machining. In this article, we delve into the nuances of high precision part finishing and explore the distinct advantages offered by 11-axis machining over its 5-axis counterpart.

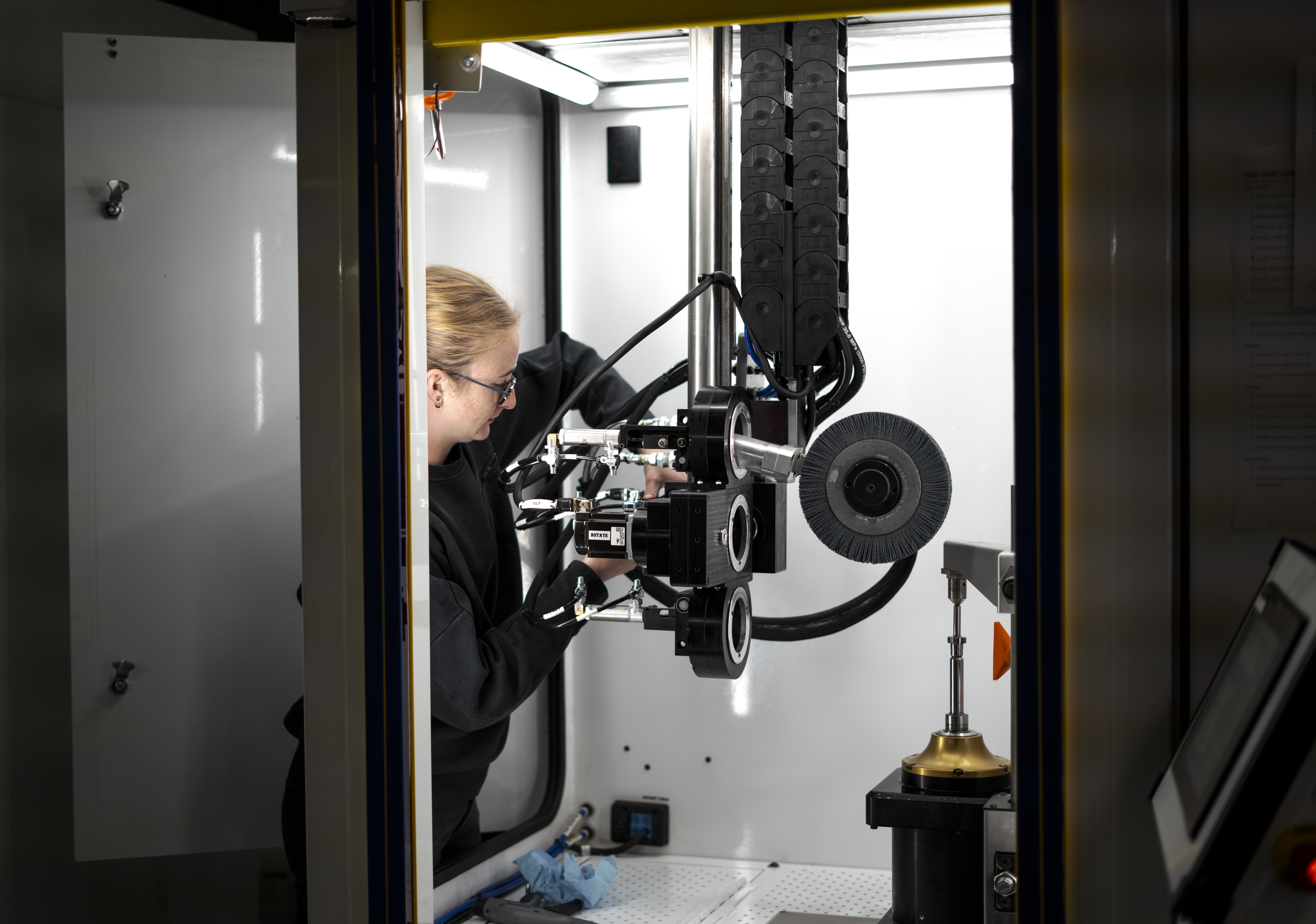

Deburring and Part Finishing in the Aerospace Sector: Exceeding Industry Standards

In the dynamic world of aerospace engineering, precision and quality are paramount. Every component, no matter how small, plays a crucial role in the overall performance and safety of an aircraft. One often overlooked but essential process in aerospace manufacturing is deburring and part finishing. This article explores the significance of deburring, its role in meeting industry standards, and the latest techniques employed by top engineers in the aerospace sector.

Mastering Precision: A Comprehensive Guide to Overcoming Part Finishing Challenges

In the intricate realm of manufacturing, achieving precision in part finishing is an ongoing pursuit that directly influences the quality and functionality of the final product. This comprehensive guide explores the common challenges encountered in part finishing and offers valuable insights into overcoming these hurdles with the help of advanced deburring and chamfering machines.