What Is Gear Shaping?

In precision manufacturing, producing accurate and reliable gears requires the right cutting process and just as importantly, proper finishing. The gear shaping process is one of the most versatile gear-cutting methods used today, especially for complex and internal gear geometries.

Understanding Gear Shaping and Deburring in Manufacturing

In precision manufacturing, producing accurate and reliable gears requires the right cutting process and just as importantly, proper finishing. The gear shaping process is one of the most versatile gear-cutting methods used today, especially for complex and internal gear geometries. This article explores what gear shaping is, how it differs from other gear-cutting methods, and why deburring and finishing are critical steps after shaping.

What Is Gear Shaping?

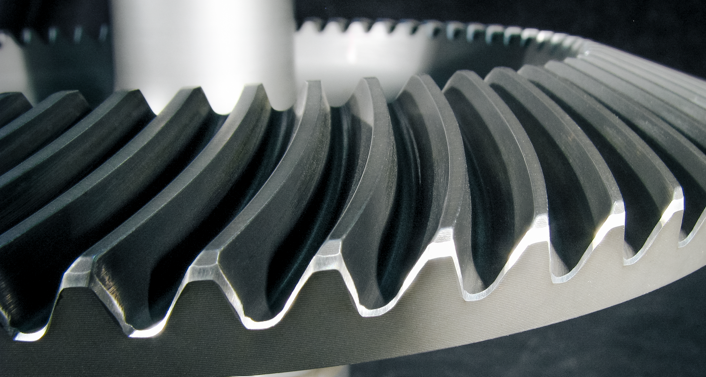

Gear shaping is a machining process used to cut gear teeth using a reciprocating cutting tool, known as a gear shaper cutter. The cutter and the workpiece rotate in a synchronized motion while the cutter moves up and down, gradually forming the gear teeth to the required profile.

Unlike continuous cutting processes, gear shaping removes material in incremental strokes. This makes it especially well suited for producing internal gears, splines, and gears with complex or interrupted geometries that cannot be easily produced through other methods.

Gear shaping is widely used in industries such as automotive, aerospace, defense, and heavy equipment manufacturing, where precision and flexibility are essential.

How Does Gear Shaping Differ From Other Gear Cutting Methods?

Gear shaping is one of several methods used to create gear teeth. Each process has strengths depending on the gear design and production requirements.

Gear Shaping:

Uses a reciprocating cutter and excels at producing internal gears and gears located close to shoulders or obstructions. It offers high accuracy and flexibility but is generally slower than continuous cutting processes.

Gear Hobbing:

Uses a rotating hob in a continuous cutting motion. It is highly efficient for producing external spur and helical gears in high volumes but cannot produce internal gears.

Gear Milling:

Uses a form cutter on a milling machine. It is often used for prototypes, repairs, or low-volume production runs but lacks the speed and precision of shaping or hobbing.

Gear Broaching:

Removes the full gear profile in a single pass using a broach. It is extremely fast for high-volume production but requires specialized tooling and is less flexible.

Gear shaping remains a preferred solution when gear geometry or part constraints limit the use of other cutting methods.

Why Is It Important to Remove Burrs After Gear Shaping?

Like all gear-cutting processes, gear shaping produces burrs small, sharp edges or raised material left behind at the tooth edges and root of the gear. These burrs are a natural byproduct of metal removal but can create serious issues if left unaddressed.

Burrs can:

Create safety hazards during handling and assembly

Interfere with proper gear meshing and performance

Accelerate wear and noise in gear systems

Prevent accurate inspection and measurement

In high-precision applications, even minimal burrs can negatively affect performance and reliability.

Why Is Deburring Necessary for Shaped Gears?

Deburring is the process of removing burrs and refining sharp edges after machining. For shaped gears, deburring is not simply a cosmetic step it is essential to overall gear function and longevity.

Proper deburring:

Improves gear engagement and load distribution

Reduces stress concentrations at tooth edges

Enhances surface finish and dimensional accuracy

Ensures gears meet quality and safety standards

As gear designs become more complex and tolerances tighter, consistent and repeatable deburring becomes increasingly important.

What Is the Effect of Proper Gear Deburring?

The effects of effective deburring extend well beyond appearance:

Improved Durability:

Removing burrs reduces the risk of micro-cracks and premature gear failure.

Enhanced Precision:

Clean edges allow gears to perform as designed, especially in high-load or high-speed applications.

Better Surface Finish:

A smoother finish improves efficiency, reduces friction, and can help prevent corrosion.

Increased Manufacturing Efficiency:

Well-finished gears assemble more easily, operate more reliably, and reduce costly rework or downtime.

Gear Shaping and Finishing With James Engineering

While gear shaping produces accurate and complex gear geometries, the process is not complete without proper finishing. That’s where James Engineering plays a critical role in the manufacturing workflow.

James Engineering specializes in automated deburring and edge-finishing solutions designed to handle the demands of precision-machined components, including shaped gears. Their machines are built to deliver consistent, repeatable results whether the application requires lights-out automation for high-volume production or flexible setups for complex parts.

By integrating advanced deburring and finishing systems after gear shaping, manufacturers can ensure their gears meet performance, safety, and quality requirements without sacrificing efficiency.

Conclusion

Gear shaping is a powerful and versatile gear-cutting process, particularly for internal and complex gear designs. However, the true performance of a shaped gear depends on what happens after cutting. Deburring and finishing are essential steps that protect functionality, extend service life, and uphold manufacturing quality.

Understanding gear shaping and pairing it with the right finishing solution helps manufacturers produce gears that perform reliably in even the most demanding applications.