Surface Finishing Reinvented | Reshaping the Future of Metal Surface Finishing Machines

The metal surface finishing process demands precision, speed, and consistency—qualities that are essential in today’s competitive manufacturing landscape. From aerospace components to heavy machinery, every metal part must be properly treated to meet high-performance and durability standards. That’s where James Engineering steps in. Our innovative metal surface finishing machines are redefining what’s possible in surface treatment by combining automation, flexibility, and unmatched precision.

Whether you're researching the types of metal surface finishing treatments, evaluating your current processes, or searching for the right “metal surface finishing machine near me”, James Engineering’s MAX Systems provide the industry’s most advanced and adaptable solution. We’re not just improving the types of surface finishing processes available—we’re building machines that evolve with your production demands.

What Is Surface Finishing of Metal?

Surface finishing of metal refers to processes that alter the surface of a metallic part to achieve a desired texture, smoothness, or protective layer. These treatments may serve aesthetic, functional, or performance-related purposes—ranging from removing imperfections to preparing a surface for coating or painting. The types of metal finishing vary widely, including deburring, polishing, chamfering, and radiusing.

Each of these methods serves a unique role in the production lifecycle, and finding the right metal surface finishing machine tools can be the difference between efficient output and costly downtime.

Introducing the MAX Systems: The Pinnacle of Surface Finishing Innovation

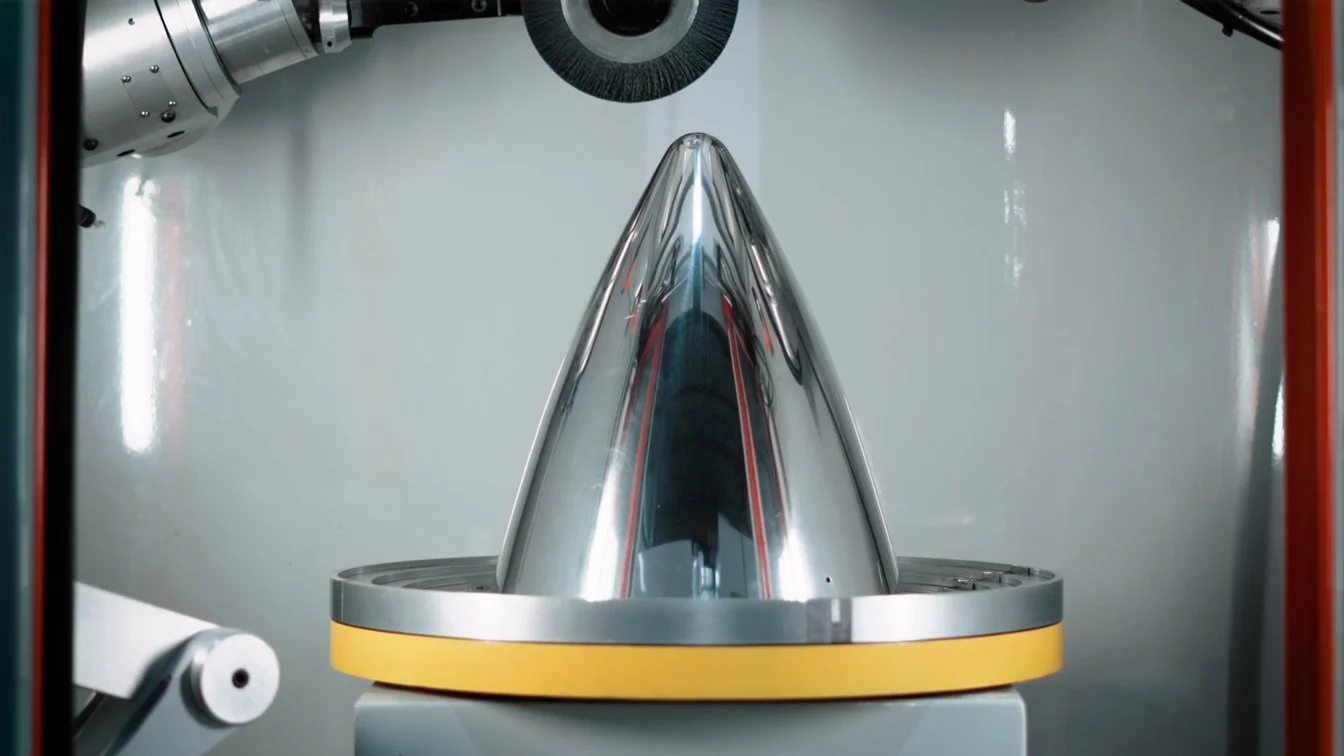

The MAX System from James Engineering is not just another machine on the floor—it’s the ultimate platform for all your metal surface finishing machine techniques. It’s engineered from the ground up to do more than just remove burrs; it delivers a complete finishing solution in one automated system.

Multi-Function Tooling for Any Finish

Unlike traditional equipment, MAX Systems allow for quick swapping of an unlimited array of tools. These tools can not only deburr but also chamfer, polish, and radius metal parts in one fluid cycle. That means fewer machines, faster cycles, and better results—all with a single investment.

With MAX Systems, your team can transition between types of metal surface finishing treatments with just a push of a button. It’s a true all-in-one solution, built to serve shops handling everything from high-mix low-volume parts to heavy-duty industrial runs.

The MAX Surface Finishing Cycle: Precision in Every Pass

At the heart of every MAX Systems machine is our custom-crafted surface finishing cycle, engineered for total precision and consistency.

360° COVERAGE

Our finishing process features complete 360-degree contact, reaching every contour and edge. This ensures that burrs, oxidation, or imperfections are removed uniformly, no matter the geometry or orientation of the part.

DYNAMIC ROTARY TABLE

The MAX Systems’ dynamic rotary table operates between 5 and 1000 RPM, rotating in both directions to tackle imperfections from every angle. This dual-motion design enhances precision while reducing cycle times. It's built to ensure that no spot goes untreated.

OVERHEAD SERVO & SMART TOOL SYSTEM

Using an overhead servo arm and high-durability tool options, the MAX Systems delivers delicate yet powerful finishing action. The tools adjusts in real-time to match part geometry, ensuring no over-grinding or missed zones. Whether you're preparing aerospace gears or large-scale industrial plates, the MAX Systems adapts to your needs with intelligent motion and force control.

DESIGNED FOR SPEED AND SIMPLICITY

Time is money in manufacturing, and the MAX Systems delivers where it counts.

LIGHTNING-FAST SETUP

Operators can load parts and initiate cycles with minimal effort. No complex retooling, no in-depth programming. Whether it’s your first shift or your 500th run, the MAX System’s interface and modular setup keep workflows efficient.

MINIMAL TRAINING REQUIRED

Built for intuitive use, the MAX requires little to no specialized training. This lowers barriers to entry, reduces errors, and ensures your team stays productive from day one.

CONSISTENT RESULTS ACROSS EVERY MATERIAL

MAX Systems are not limited by part size or material type. Whether you're working with stainless steel, aluminum, titanium, or exotic alloys, the MAX System delivers consistent, repeatable finishes. Our systems are built to handle both soft and hard metals without compromising on edge quality or surface smoothness. Even complex geometries or irregular contours are processed with precision thanks to adaptive tooling and intelligent motion control. This ensures every part meets strict quality standards—no matter the material or application.

Why James Engineering?

James Engineering has spent decades perfecting the art of metal surface finishing machine design. We’re more than a machine builder—we're a full OEM (Original Equipment Manufacturer) that controls every aspect of development, from hardware to software. This lets us optimize every feature for performance, reliability, and customer adaptability.

We don’t build “one-size-fits-all” machines. We build tools tailored for manufacturers who need flexibility, speed, and quality without compromise.

So whether you're rethinking your metal surface finishing process, upgrading outdated technology, or simply searching “metal surface finishing machine near me,” James Engineering is ready to help you finish stronger.

Experience the Future of Surface Finishing

From a wide range of types of metal surface finishing treatments to fully automated production lines, James Engineering is redefining what’s possible in modern manufacturing. Whether you're upgrading outdated equipment or expanding capacity, our MAX Systems are engineered to evolve with your production needs.

Trusted by top industry leaders, MAX Systems delivers intelligent automation, unmatched flexibility, and flawless results. With the ability to deburr, chamfer, polish, and radius—all in one cycle—our systems outperform traditional methods in both speed and consistency.

If you're searching for a metal surface finishing machine near me or exploring better metal surface finishing machine techniques, MAX Systems is the future-ready solution.

Don’t settle for the ordinary—invest in the extraordinary. Contact James Engineering today to learn how our MAX Systems can transform your finishing process and elevate your entire operation.