Metal 3D Printing Surface Finish | Solving Challenges with James Engineering

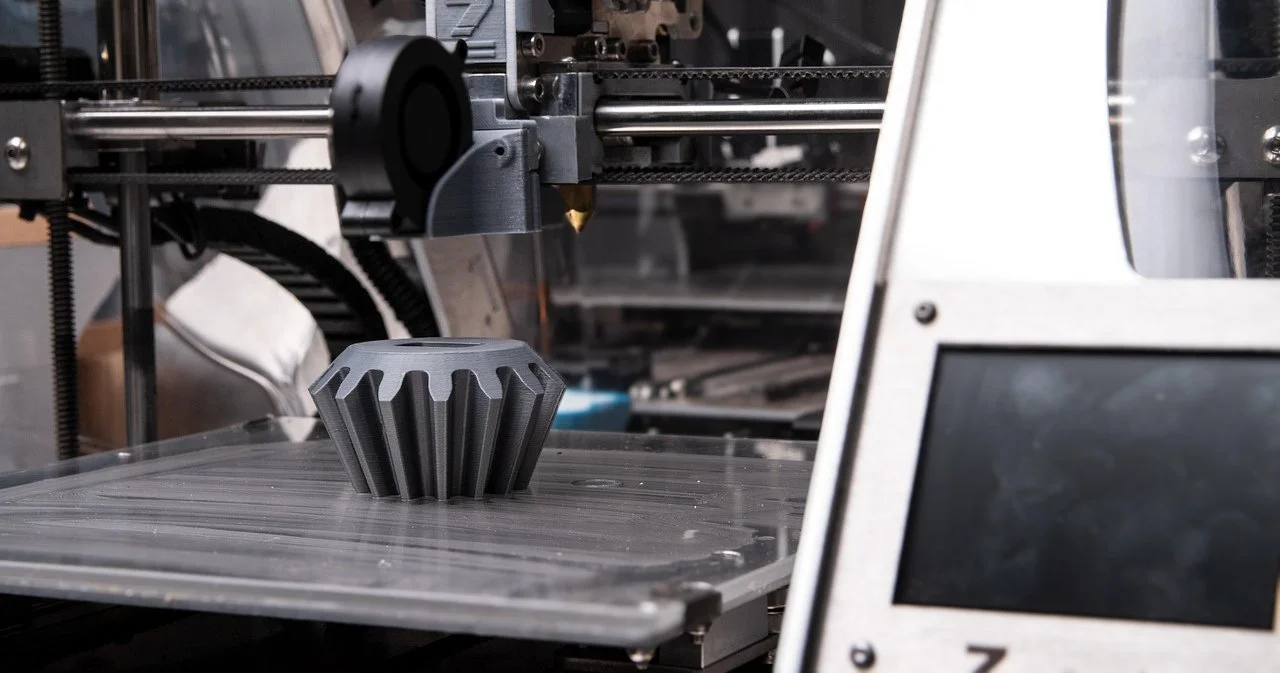

Metal 3D printing surface finish is one of the most critical challenges in additive manufacturing. While metal additive parts offer complex geometries and fast production, they often suffer from poor surface quality, rough textures, and inconsistent tolerances. That’s where James Engineering comes in—with purpose-built 3D printing finishing machines, intelligent 3D printing finishing tools, and precision-engineered 3D printing smoothing machines designed to elevate post-processing for additive parts.

Whether you’re producing lightweight aerospace brackets or medical implants with intricate contours, your additive manufacturing surface finish can’t be left to manual processes or inconsistent solutions. James Engineering’s MAX Systems offer an automated, reliable, and scalable way to achieve high-quality finishes that match or exceed traditional subtractive methods.

The Finishing Problem in Additive Manufacturing

Even with advancements in powder-bed fusion, DMLS, and other additive technologies, 3D-printed metal parts typically emerge with high surface roughness, partially sintered particles, and sharp micro-edges. These defects can compromise part performance, wear resistance, and even regulatory compliance.

Traditional surface finishing methods like hand sanding or tumbling are not only labor-intensive but also lack consistency—especially across batches or complex geometries. What additive manufacturers need is a system that can smooth, polish, and deburr with speed, accuracy, and repeatability.

MAX Systems: Purpose-Built for Additive Surface Finishing

James Engineering has developed a range of tools specifically designed to address additive surface finish needs. Our MAX System is a fully automated finishing platform that can be outfitted with custom heads for polishing, chamfering, deburring, and smoothing—all in a single cycle.

Thanks to our patented compliant technology, the MAX System can adapt in real time to the shape and material hardness of any 3D-printed part. This makes it ideal for finishing both high-value prototypes and production-grade parts with complex geometries and tight tolerances.

You no longer have to rely on inconsistent manual finishing or underpowered aftermarket solutions. Our 3D printing smoothing machines and tools deliver precision-polished results with minimal operator input and no part distortion.

From Micro Parts to Large Builds—No Size Limitations

Unlike traditional post-processing systems, James Engineering’s machines aren’t restricted by part size. Whether you’re processing small dental components or large-format structural parts, our MAX platform can scale accordingly. For shops running diverse builds from their printers, this is a game-changer.

Even better, our saved “recipe” functionality allows you to program and repeat finishing cycles with one button press. That means consistent finishing from the first part to the thousandth.

Built for the Future of Additive Manufacturing

With the rapid adoption of metal 3D printing in aerospace, defense, and medical industries, the demand for better finishing solutions has never been higher. Our systems not only meet that demand—they’re built to exceed it.

If you’re ready to take your metal 3D printing surface finish to the next level, contact James Engineering today. Discover how our purpose-built 3D printing finishing machines and tools can bring automation, consistency, and perfection to your additive workflows.