Automatic Deburring and Chamfering

Metal finishing is no longer a secondary operation, it’s a defining factor in product quality, production efficiency, and long-term manufacturing success.

Automated Metal Finishing That Scales: The James Engineering Advantage

Metal finishing is no longer a secondary operation, it’s a defining factor in product quality, production efficiency, and long-term manufacturing success. As parts become more complex and production demands increase, manufacturers are under pressure to deliver consistent finishes at higher volumes with fewer resources. This is where James Engineering stands apart.

James Engineering designs and builds advanced automated metal finishing machines that replace slow, inconsistent manual processes with precision-driven, repeatable results. From deburring and chamfering to polishing, radiusing, and surface finishing, our MAX Systems redefine what modern finishing equipment should be.

The Problem with Traditional Metal Finishing

Many manufacturers still rely on outdated finishing methods: hand deburring, tumbling, fixed robotic cells, or single-purpose machines. While these approaches may work in limited scenarios, they often introduce bottlenecks, quality variation, and excessive labor costs, especially as part complexity and volume increase.

Manual finishing struggles with consistency. Tumbling lacks control. Robotic systems can be expensive, inflexible, and difficult to retool. In high-mix or high-volume environments, these limitations add up quickly.

James Engineering built MAX Systems specifically to solve these challenges.

One Platform. Unlimited Finishing Capability.

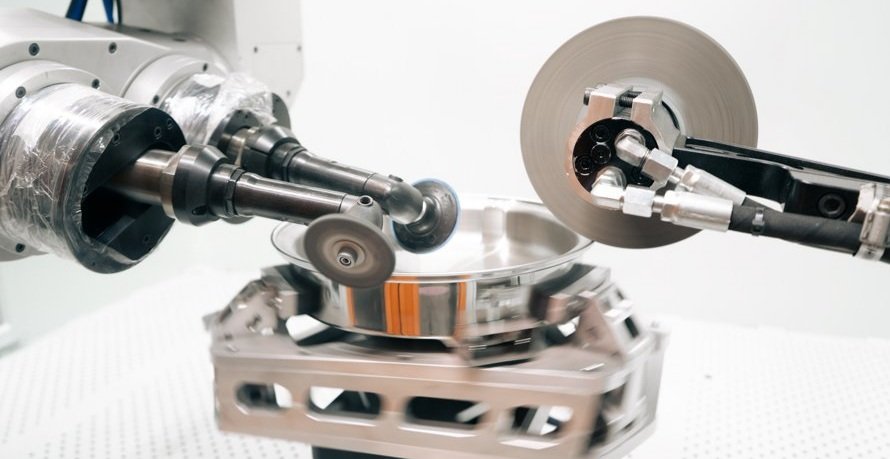

The MAX Machine is not a single-purpose tool, it’s a modular, multi-function finishing platform. Designed to accommodate an unlimited array of tool heads, MAX can deburr, chamfer, polish, radius, and surface-finish parts within the same system.

Quick-change tooling allows operators to transition between processes in minutes, not hours. This means fewer machines on the floor, less downtime between jobs, and a dramatic increase in overall throughput.

Whether you’re finishing small precision components or large industrial parts, MAX adapts to the job, not the other way around.

Precision Through Compliant Technology

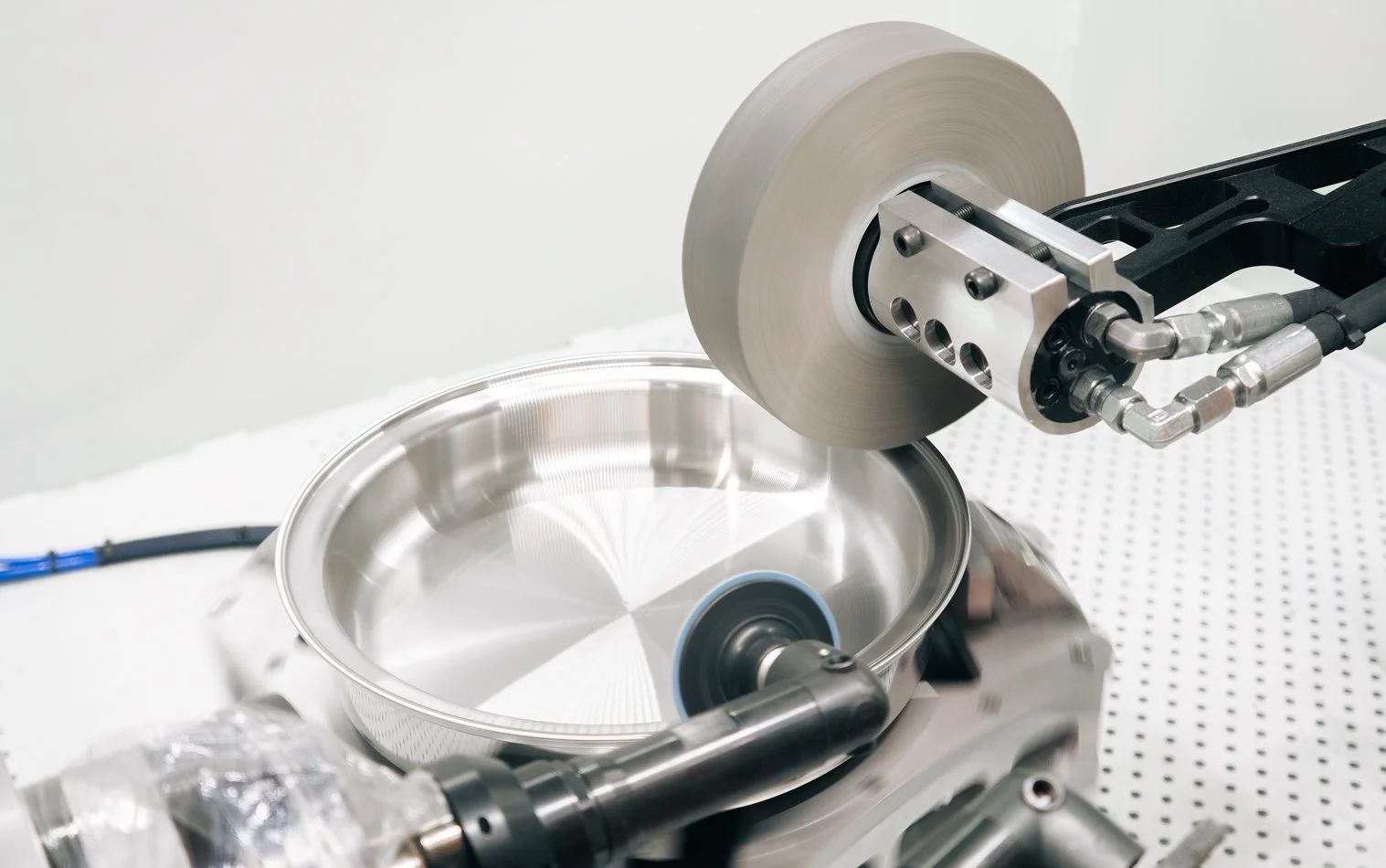

At the core of every James Engineering machine is patented compliant technology. Unlike rigid systems that rely on fixed pressure and perfect part conditions, MAX dynamically adapts to part geometry, surface variation, and tool wear in real time.

The result is consistent material removal without over-grinding, edge burn, or part damage. Even complex geometries, internal features, and irregular contours are finished evenly and repeatably.

This level of control allows manufacturers to achieve high-end finishes while extending tool life and reducing scrap.

Built for High Volume, Ready for Lights-Out

Efficiency doesn’t stop at cycle time. James Engineering machines are engineered to eliminate setup delays, operator dependency, and unnecessary downtime.

Saved finishing “recipes” allow operators to recall exact cycles with a single button press. This enables fast changeovers, repeatable results, and seamless production across shifts or product lines.

For manufacturers pushing throughput even further, MAX Systems can be configured for fully automated, lights-out operation, running unattended while maintaining the same precision and consistency as attended cycles.

Full OEM Control Means Full Customization

James Engineering is a full OEM manufacturer. Every component, from machine frames and control arms are designed and built in-house.

This gives us complete control over performance, reliability, and customization. Machines can be tailored to specific materials, part sizes, cycle requirements, and future expansion needs. As production evolves, MAX Systems evolve with it.

This is not a one-size-fits-all solution, it’s a platform engineered around your operation.

Sustainable by Design

Modern manufacturing demands smarter use of resources. James Engineering machines support optional wet finishing cycles with closed-loop filtration systems that recycle fluids for reuse. Combined with long-life abrasives and compliant engagement that prevents overuse, MAX Systems significantly reduce consumable waste.

No scrap. Longer tool life. More efficient finishing. Sustainability is built into the process, not added as an afterthought.

Proven Across Industries, Built for What’s Next

James Engineering machines are trusted by manufacturers across aerospace, automotive, defense, medical, additive manufacturing, and heavy industry. From small precision parts to high-volume production runs, MAX Systems deliver consistent results at scale.

We’ve helped manufacturers increase output, reduce labor, improve quality, and future-proof their finishing operations, right in our hometown in Colorado and across coastlines.

Supporting the Next Stage of Your Manufacturing Operation

Every manufacturing operation evolves. The systems that worked yesterday were the right tools for their time and the companies that succeed long-term are the ones that know when it’s time to take the next step.

James Engineering exists to support that evolution. Our MAX Systems are designed for manufacturers who are growing, refining processes, and looking for ways to increase consistency, throughput, and flexibility without disrupting what already works. We don’t replace experience, we build on it.

By integrating advanced automation, compliant technology, and modular tooling, James Engineering helps manufacturers elevate their finishing operations while protecting quality, labor efficiency, and long-term investment. The result is not a dramatic overhaul, but a confident step forward.

From facilities in our hometown in Colorado to operations across coastlines, we work alongside manufacturers as a trusted partner, adapting machines to real production needs and supporting the people who keep those operations running.

If you’re exploring ways to strengthen your finishing process, streamline production, or prepare for future demand, James Engineering is here to support you. Contact our team to learn how a MAX System can complement your operation and help your customers continue to win.

Part Deburring Machine “Compliance” | The Missing Tech of Manufacturing

Part deburring machine manufacturers face several challenges with the tedious part finishing process. Whether it’s large or small parts, part deburring machines' biggest challenge may be an issue that isn’t discussed so often. That is machine compliance. Machine compliance is important not only in part machine finishing but also in almost every aspect of machining….

MANUFACTURING’S BIG PROBLEM

Part deburring machine manufacturers face several challenges with the tedious part finishing process. Whether it’s large or small parts, part deburring machines' biggest challenge may be an issue that isn’t discussed so often. That is machine compliance. Machine compliance is important not only in part machine finishing but also in almost every aspect of machining. Several methods have been developed to cope with this issue, but there’s one that proves to be a true solution to the problem. First, what exactly is machine compliance?

MACHINE COMPLIANCE

Though not as precise, we as humans can visually see and understand the dynamics of the part we are working on. We can make adjustments accordingly and make the needed changes for the differences part to part. When a robot or CNC is working on a part it is only comprehending the program it is running and not the actual part being machined. In a perfect world, every part would be the exact same and this would work great, but there is never a truly perfect part.

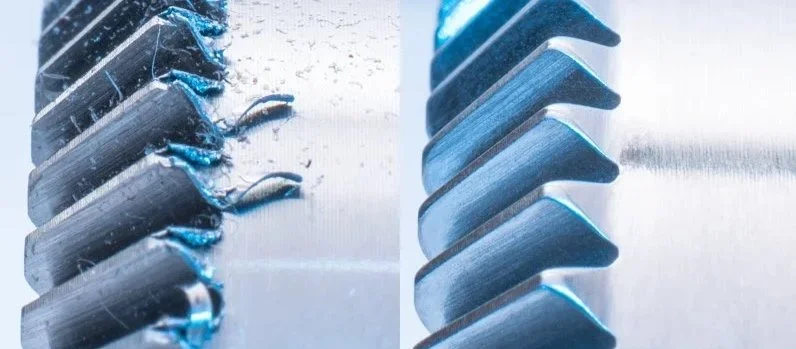

Even with smaller machined parts, unpredicted shrinking and expansion occur when cuts are made due to stress relief of the metal. This becomes a much more obvious problem with larger cuts or processes like forging, casting, or stamping that leave an excess flash seam. Burrs themselves also are never the same. These factors all impact the precision of the part and lead to unpredicted tool wear.

Abrasives used to deburr and finish parts tend to wear down at a quicker rate than normal tools. With even small inconsistencies the wear of the tools is hard to predict. This causes the machine to over or under-engage when machining a part.

OVER-ENGAGE

Over-engaging occurs when a machine gets too close to the part. Stress from the added force will cause tools to break and risk damage to the part itself. If a part is just slightly bigger than the original blueprint a machine running the same cycle will not make up for the difference in the part and will over-engage the part.

UNDER-ENGAGE

Under-engaging occurs when not enough pressure is applied or the tool misses the part completely. This will lead to poor precision or no finish at all on a part. Excess tool wear can be caused by the machine over-engaging and when a tool wears excessively the part will be under-engaged since there is less surface of the tool than expected.

Sensors and Algorithms

Sensors and algorithms have attempted to solve the issue of inconsistencies that lead to over/under-engaging but neither of these have proven to be a true solution. Because tool wear isn’t perfectly consistent, algorithms written to predict the wear result in varying levels of precision and fail over time. Sensors also pose more issues. With how abrasive finishing tools can be, excess abrasive and burrs can interfere with the sensor and lead to inconsistencies. Wet cycles that are run to keep down debris and clean the part cause the sensors to completely lose the surfaces and fail.

Mechanical Machine Compliance

The solution that has kept James Engineering’s part deburring machines running for 40+ years is our patented machine compliance. With precision axes and high-quality air motor tool arms, the tools can correctly comply with surfaces. Avoiding the use of sensors or algorithms, the part deburring machines take a mechanical approach to the issue. Once cycles are set up, the machine tools adjust part to part based on applied pressure.

Kitchen pot’s typical warping post machining. When spun on rotary table the difference of 1/8” can be seen. (James Engineering’s automated deburring systems)

Machine compliance is a critical but overlooked challenge in manufacturing and part machine deburring. Challenges lead to costly issues like tool wear, damage caused by over-engagement, and poor performance of parts due to the lack of precision. These problems not only increase operational costs but also require significant expertise to manage. Traditional solutions involving sensors and algorithms will fail due to the unpredictable nature of machining environments.

James Engineering's patented mechanical machine compliance eliminates these concerns. By automatically adjusting to each part’s unique characteristics without the need for sensors or algorithms, these part deburring machines eliminate the need for expert intervention, lower costs, and ensure consistent, high-quality finishes.