The Machine Shop at James Engineering

Get an inside scoop about the machine shop at James Engineering from a Q&A with lead engineer, Dave Schlosser, and company vice president, Scott Richards.

The Colorado-based OEM shop is known for their one-of-a-kind deburring and chamfering machines, but they also have a precision-focused machine shop that’s willing to take on any project that comes their way. If you’re in the market for a low to medium volume machine shop who guarantees quality products, reach out to James Engineering today at (303) 444-6787.

—

What is our shop capable of?

Dave: We have 3 mills and 2 lathes. One of the mills has 4th axis capability. We’re capable of holding concentricity within 5/10ths in most cases without have to do any crazy set ups. We can do round parts, square parts, just about any shape part that you want.

Scott: We’ve got a live tool lathe with a bar feed option and multiple seats of programming software. We’ve got that 4th axis mill, another smaller mill with a 20-inch bed, and we’ve got a 60-inch bed large mill.

How many parts a week do we typically make?

Dave: That’s pretty subjective because we do short run production, so most of our time isn’t spent making parts, it’s getting ready to make a part and getting a part set up to run. Typically, we could spend half hour programming, half our setting up, and basically we could run for 15 minutes and then be done (in some cases). We can’t really quantify the quantity of parts per week because we’re more set up to be a tooling or prototype shop versus a production shop.

Can customers send in their own designs?

Dave: We quote on stuff and have stuff made for outside companies. We have engineering services, so people can send in a concept and we could do the whole thing, or they could send in a thing that’s basically done and we could create drawings for them, things like that. We have start-to-finish capability, or we can pick up a project that they’re already halfway through. We can also provide good drawings, give them a model.

What are some basic jobs we do frequently?

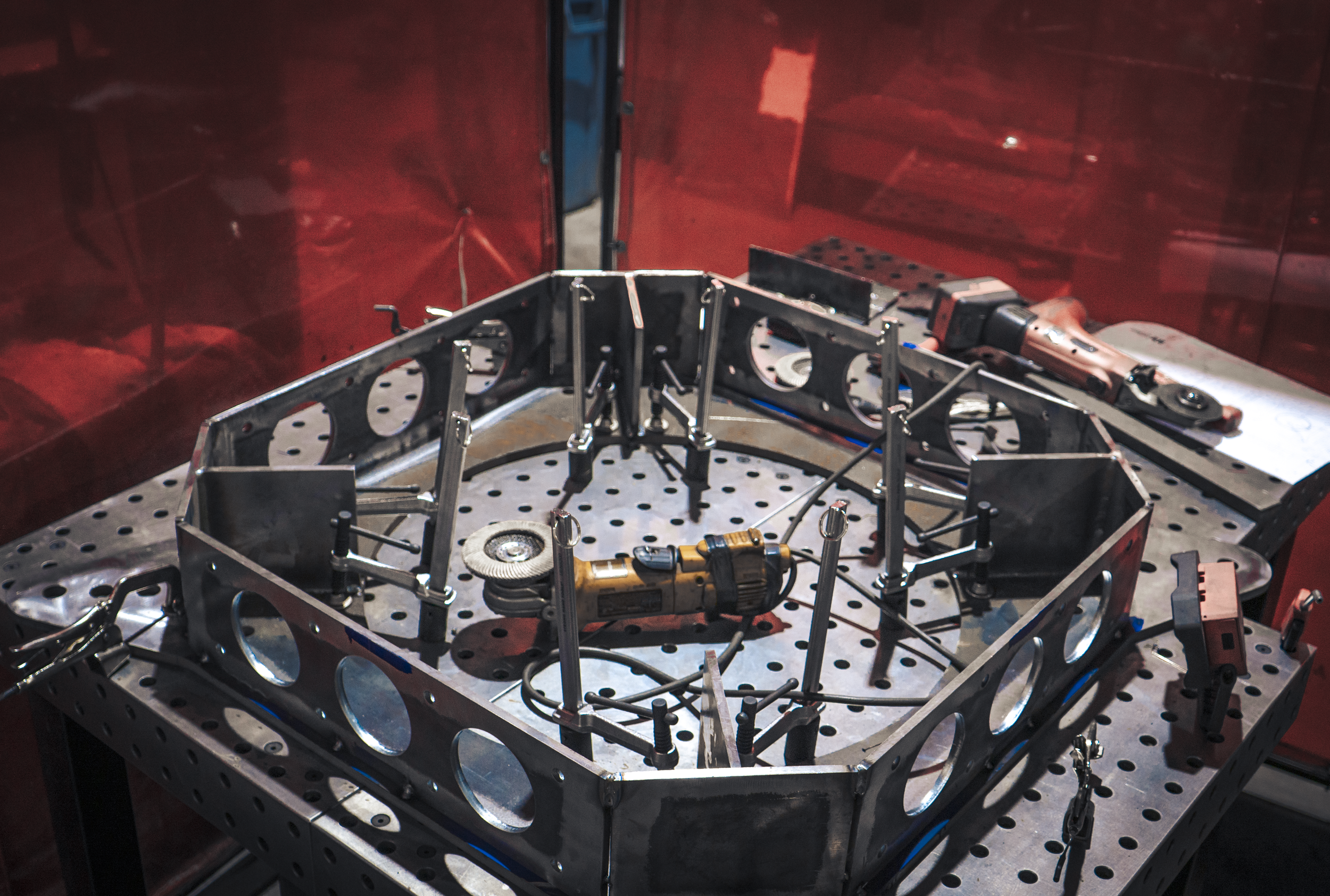

Dave: We do a lot of gun parts, automotive stuff, motorcycle parts. It really is just a gamble. Basically, anybody who walks into the door with a project, we can take a look at it and see if it fits our capabilities fairly easy and we’ll do it. We’ve done a lot of welding jobs lately, too. We’ve done a lot of stuff for RoboCon; we’ve made a lot of platforms and fixturing. We’ve made brownie bowls, and stuff for volleyball companies, it doesn’t really matter what industry comes in.

Scott: So we’ve got a lot of high end, high precision parts that we make. For example, we’re making a mount for a vehicle right now. Our perfect job is a volume job. We’re really looking for anything from prototype to a few thousand parts a week. I wouldn’t call ourselves high volume where we’re tens of thousands of parts per week, but we’re definitely looking for that low to medium volume area.

What makes our shop stand out?

Dave: Our attention to detail and the quality of our parts. That’s something that we take a lot of pride in. We try to go that one step above, whether it’s by deburring or not putting a scratch on it by pushing it across surfaces, things like that. We take really good care of all the parts we make, and it’s a lot easier to go in and get the quality you’re looking for when you’re not making thousands and thousands of parts.

Why is it significant for our machine side of business that we make our own parts in-house?

Dave: We can control our own quality because our standards are really high. To be able to get the tolerances and stuff we need we can hardly get other people to make them for us. We put a dimension on a drawing and expect you to hold it, so in some cases we put really tight tolerances on things with reason, and when other companies see those tight tolerances the cost goes up automatically (whether it’s justifiable or not). It’s more cost efficient for us to do it.

Scott: We have to make all of these parts here in-house because we really can’t afford to job much of this out. We’ve got to keep our profit margins where they need to be. We have to hold pretty precision fits because we’ve got a 3.2 million resolution encoder here turning all of these [parts] on this five-axis manipulator.

How do your own deburring machines fit into the machine shop process?

Scott: When we make these parts, we do a lot of in-machine deburring. We’ll go through and we’ll machine this edge with a chamfer tool. But the problem is, when we machine the edge with the chamfer tool, the chamfer tool creates two sharp edges. We still have this problem where a technician has to go in with Scotch-Brite and deburr this. So we don’t want that abrasive to get into our CNC machine, because if that abrasive gets into our machines, it gets down into ways and slides and it wears the machine out. That’s where the market is for our deburring machine.

The Torchbearer

A spotlight on Masenn Lewis and his welding journey.

Bent over a worktable and concealed behind a scratched hood decorated in flames, Masenn Lewis, lead welder at James Engineering, is laser-focused on the project at hand: welding components for a cement 3D printer.

Lewis has been a welder at James Engineering since March of 2022. Prior to finding his place at the family-owned deburring and chamfering machine shop located in Broomfield, Colorado, Lewis had eight years of welding experience, working on anything from firetrucks to underwater pipelines. He attended the Divers Institute of Technology located in Seattle, where his underwater welding journey began once he’d earned his certificate. “[As an underwater welder] I’ve been all over the place. I was in Dutch Harbor, Alaska for almost a year, working with crab fishermen doing underwater construction. My favorite place was at a dam job in Austin, Texas.” Underwater welding is argued to be the most dangerous career in the country, with a fatality rate of 15%. After sustaining major injuries during his time as an underwater welder, Lewis moved from Texas to Colorado to look for something a bit drier.

Masenn lewis

“I was up in [Colorado] doing a handful of interviews,” he recalls, “and [James Engineering] offered to hire me on the spot.”

His skills did not go unnoticed, and James Engineering just knew they had to have him on their team.

But just as Lewis has played a vital role at James Engineering, they have played a major part in Lewis’s professional life. “I’ve worked for other companies where you don’t have access to the engineers to figure out what problems are happening, [but here] I’m able to talk to the engineers whenever I need to,” he says. “It’s a strong suit of the company.” Without collaboration, the manufacturing industry as a whole would fail. James Engineering highly values teamwork, and Lewis has experienced firsthand just how valuable a strong team can be. “People here get along really well, and it makes it easier to work for sure.”

This collaboration then provides endless learning opportunities, especially in the face of hard challenges. “We’ve had to work on parts of the enclosures where it’s impossible to do what we need to do,” Lewis answers when asked what challenges he’s had to overcome during his time at James Engineering. “Jim, Scott, the engineers and I figure out different ways to get things done.”

Tips from the torchbearer

In an industry that requires so much precision, Lewis offers up a few helpful tips to those who are looking to try their hand at welding.

“Don’t be afraid to get your hands dirty. Welding is an industry where you have to work hard, there’s no reason for you to watch people work and just sit around… Always have an open mind when it comes to welding. There’s a thousand ways to do something. One time it might work and the next time it might not, so you have to keep an open mind working on stuff.”

Lewis’s mastery of welding can be seen throughout every project he’s a part of. His dedication and craftsmanship reflect the steadfast values James Engineering upholds, and it’s employees like Masenn Lewis that strengthen our very foundation as a company.