The Power of 11 Axes and Focused Deburring

11-axis deburring — Why is it significant?

3-axis and 5-axis deburring have become common practice when it comes to the essential surface finishing process. Having a machine capable of more has been nothing but a mere concept—that is, until James Engineering came along and introduced an 11-axis machine to the market.

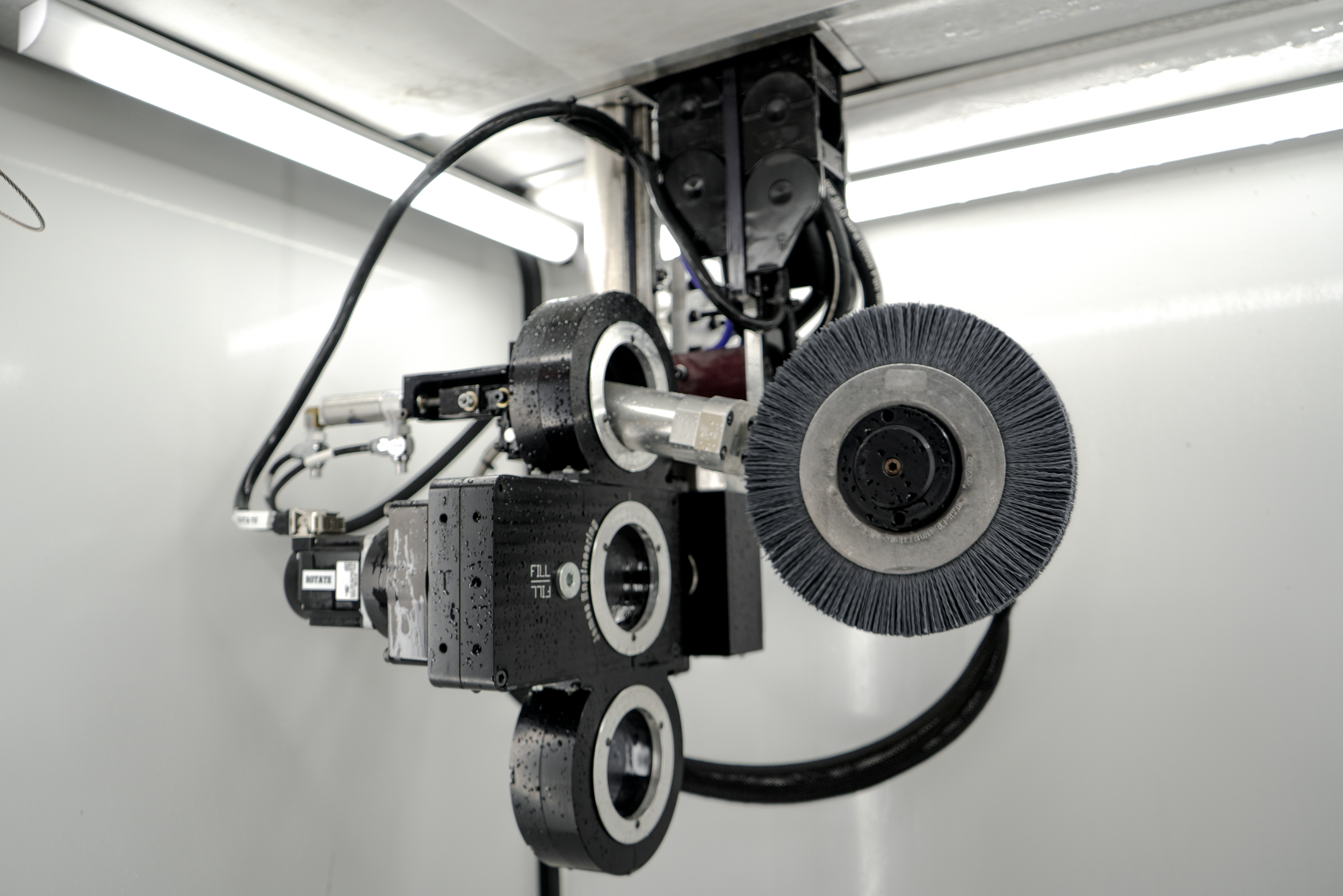

The MAX is a deburring and chamfering machine that makes 11 axes possible due to patented technologies. James Richards, the founder of James Engineering, grew exhausted constantly fixing the wear and tear on the ways and slides in his shop’s CNC machines, caused by the copious amounts of abrasive that are vital for the deburring process. So when it came to designing his own machines, made explicitly for deburring and chamfering, he installed the ways and slides on the roof instead of on the bottom of the machine. But he took it a step further when he installed a liner slide system with rolling elements. When in motion, these rollers push any harmful abrasive out of the way before it can begin to wear down the ways and slides of the machine from continued usage.

Abrasive is extremely destructive for both CNCs and robots. Measuring down to the micron level, it can easily get in between moving parts in CNCs and the rubber seals on robot joins and very quickly deteriorate their surfaces. For reference, a human hair measures up to a thousand times smaller than that of a hair. So while some may argue that CNCs are capable to handle abrasive due to its filtration system, particles that small never fully settle in washing solution when initially flushed out. This means any parts being processed in a CNC are constantly being washed with previous abrasive—an obvious problem that becomes destructive in a very short amount of time.

The MAX never has to worry about this issue. Because of this, the 11-axis system is protected and has a much longer life than any CNC or robot out there. This is especially important, as these 11 axes rely on smooth movement and mobility to work properly.

Many people prefer to deburr by hand because of precision and mobility; other methods, such as vibratory deburring, do not guarantee precision or free movement on the level that hand deburring can reach. But the problem with hand deburring is its lack of repeatable accuracy. The movement between fingers, wrist, elbow, and shoulder allow for the flexibility that’s extremely beneficial for deburring, so people have attempted to mimic this with robots. They’ve gotten pretty close, but robots lack the precision that’s paramount for deburring, making it an unreliable method. The MAX is able to combine the best elements of both—a CNC’s precision and a robot’s agility—into one. Pair that fact with its patented linear slide technology, and you’ve got a smooth and accurate machine that can reach any angle or edge without falter, and repeatably so.

Focused Deburring and how 11 axes play a part.

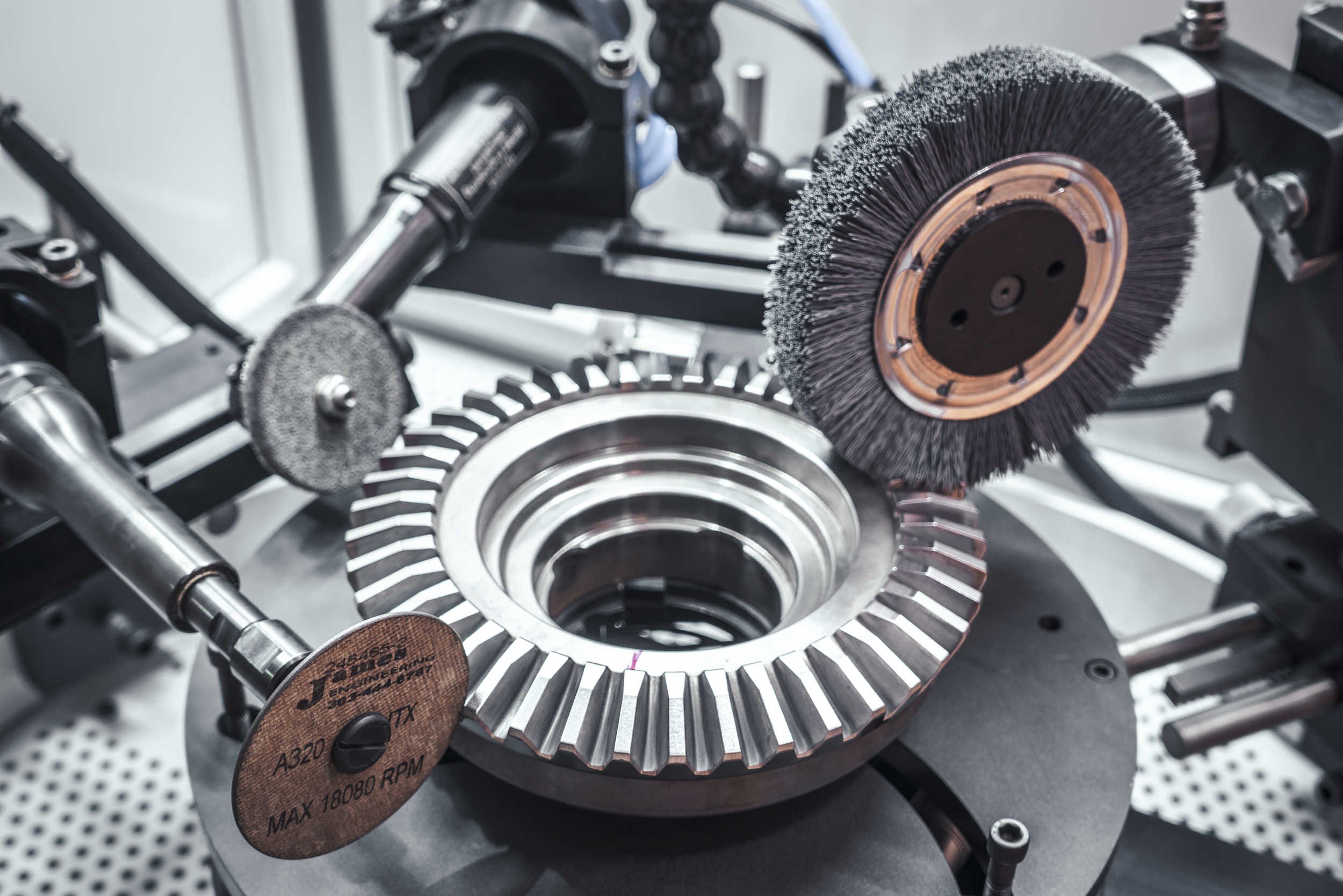

As mentioned before, mass deburring processes such as vibratory deburring can’t offer precision. During processes like these, the entirety of a gear or part is being touched. They can be masked, but masking cannot be done by machine and adds additional time-consuming labor to a cycle. Masking also cannot guarantee that areas of a part won’t get deburred anyway. This was yet another issue Richards set out to solve and lead him to creating Focused Deburring.

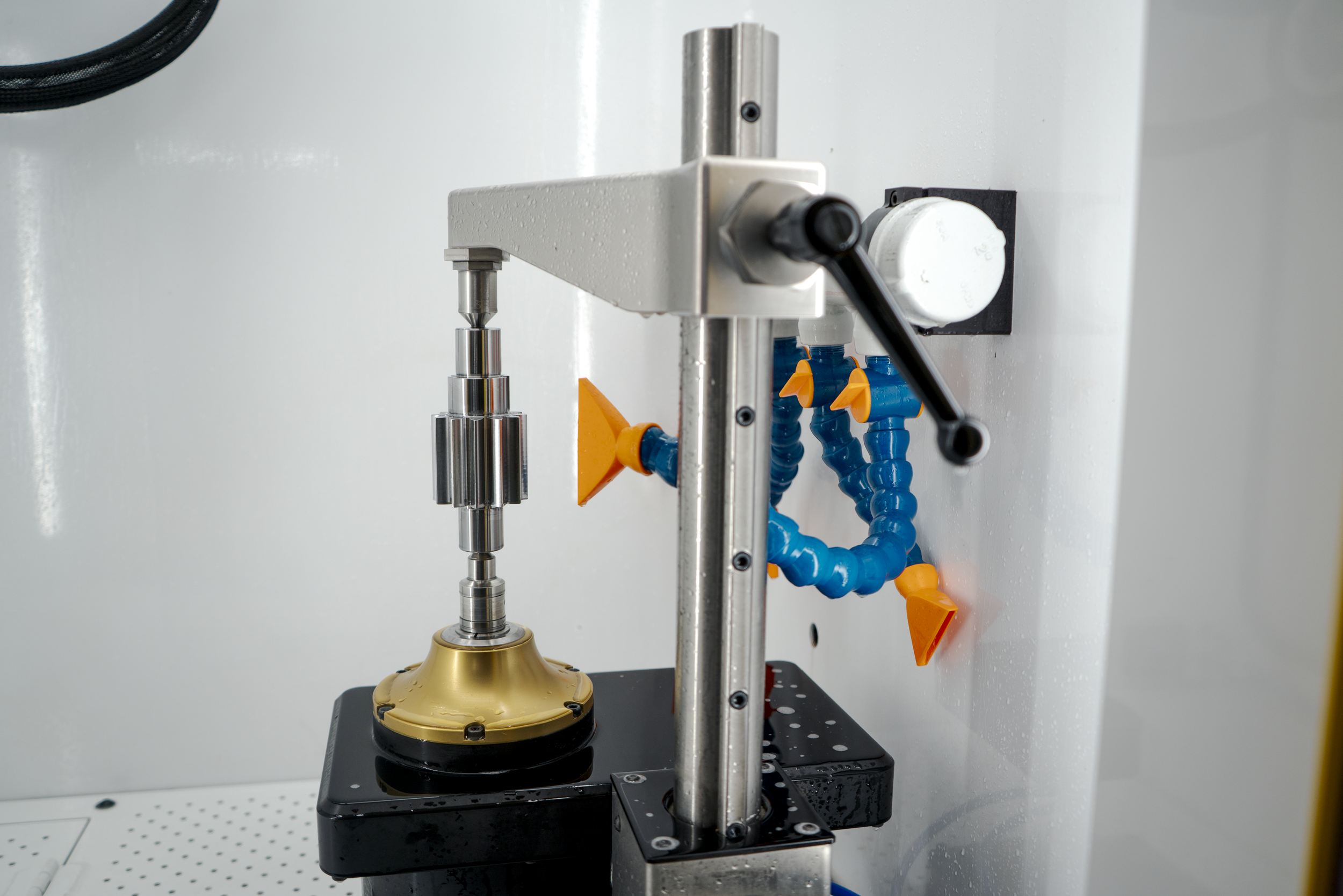

Focused Deburring requires at least 6 axes in order to work properly (the MAX has anywhere from 6-11 acis motion, depending on what model is being used), and is capable of deburring any desired area on a part/gear without touching the rest of it. The human-like motion that the MAX has makes this possible because it can move around just like an operator would in order to avoid these other areas. Then its repeatable precision comes in to play by ensuring that every single part comes out the exact same, no matter how tricky or intricate a part proves to be—reliable accuracy at its finest.

Gears are a great example of items that benefit greatly from Focused Deburring. Take a fuel pump gear, for example. These gears have high-precision journals and protruding tooth flanks, both of which rely on precision in order to be made properly. What frequently happens when these kinds of gears are deburred is the journals almost always get touched when the tooth flanks are being worked on. Operators can attempt to mask the journals, but they can still get nicked if an operator isn’t careful enough. This results in high scrap rates, wasted resources, and wasted time. With Focused Deburring, fuel pump gears can be loaded into the MAX without fear of destruction. Focused Deburring is not only limited to one type of gear or part, however; every single type of gear or part that needs deburring can be put into the MAX and come out with imperfection.

Overview

Not only is the 11-axis motion featured in the MAX an exciting change in the deburring world, but it’s also revolutionizing for every operation out there. With 11 axes, the MAX has a work envelope of 360-degrees and is capable of reaching every side of any gear or part without an operator needing to adjust it manually. It features the precision of a CNC, the mobility of a robot, and an upfraded linear slide system that makes it resistant to all abrasives. There’s not a single other machine like it on the market, and the 11-axis motion is just the tip of the iceberg. Check out the video below to see the 11 axes in action!

If you’re interested in experiencing the revolutionizing deburring machine for yourself, give James Engineering a call at (303) 444-6787, or email us at Sales@James-Engineering.com.