The Power of Compliant Technology, the Magic Behind The MAX

There’s major problem in the industry! Find out how we solve it!

See how James Engineering is solving the problem of non-inform parts , watch the video below

Precision is key.

Yet, the reality often falls short of the ideal, with parts turning out to be anything but perfect. Scott Richards, Vice President of James Engineering, delves into the heart of this challenge, shedding light on the industry's persistent problem and the innovative solution James Engineering has developed.

Solving the Problem of Non-Uniform Parts

Watch below as Scott Richards opens the discussion by addressing a common yet critical issue in manufacturing: non-uniformity. Many parts, despite appearing round, lack uniformity in dimensions. This discrepancy poses a significant challenge, particularly in processes like deburring, where precision is paramount.

Traditional approaches, including vision systems and CNC machines with complex algorithms, have failed to adequately address this issue over the past four decades. However, James Engineering's breakthrough compliant technology offers a revolutionary solution.

The Essence of Compliant Technology

Compliant technology mimics the human hand's ability to sense and adapt to surfaces in real-time. Unlike conventional methods reliant on lasers or mathematical equations, compliant technology mechanically senses and reacts to surface variations as they occur. This approach eliminates the need for predictive algorithms and ensures consistent results, even with perishable tools prone to uneven wear.

Navigating the Challenges of Inconsistent Parts

Watch as Scott delves deeper into the complexities of inconsistent parts, emphasizing the significant impact of stress relief in machining processes. As parts undergo machining, stress relief can cause unexpected distortions, leading to mismatches between the intended model and the final product. This disparity poses challenges for CNC machines and robots programmed to expect uniformity.

Addressing the Inconsistency

James Engineering's compliant technology offers a versatile solution to address inconsistencies across various manufacturing processes. By dynamically adjusting to surface variations, the technology ensures precise results, regardless of a part's shape or dimensions. Unlike traditional methods reliant on human intervention, compliant technology offers unparalleled accuracy and repeatability, enhancing overall manufacturing efficiency.

Empowering Manufacturers with Precision

In a competitive manufacturing landscape, precision is non-negotiable. James Engineering's compliant technology empowers manufacturers to achieve unparalleled precision and consistency, revolutionizing traditional manufacturing processes. By eliminating the reliance on manual intervention and predictive algorithms, the technology streamlines operations, reduces costs, and enhances product quality.

Embracing the Future of Manufacturing

As industries evolve and technology advances, embracing innovative solutions becomes imperative for sustained success. James Engineering's compliant technology represents a paradigm shift in manufacturing, offering a glimpse into the future of precision engineering.

Scott Richards's insights into the transformative potential of compliant technology underscore its significance in revolutionizing manufacturing. By bridging the gap between traditional methods and emerging challenges, James Engineering paves the way for a new era of precision and efficiency in manufacturing.

Incorporating compliant technology into manufacturing processes holds the promise of unlocking new possibilities and driving unprecedented levels of efficiency and precision. As industries continue to evolve, embracing such innovations will be crucial for staying ahead of the curve.

The Advantage of 11-Axis Machining over 5-Axis Machining in High Precision Part Finishing

In the realm of manufacturing, precision is paramount. Achieving high precision in part finishing not only enhances the quality of the final product but also significantly impacts efficiency and cost-effectiveness. Traditional machining methods have paved the way for advanced technologies like 5-axis machining, and now, the evolution continues with the advent of 11-axis machining. In this article, we delve into the nuances of high precision part finishing and explore the distinct advantages offered by 11-axis machining over its 5-axis counterpart.

In the realm of manufacturing, precision is paramount. Achieving high precision in part finishing not only enhances the quality of the final product but also significantly impacts efficiency and cost-effectiveness. Traditional machining methods have paved the way for advanced technologies like 5-axis machining, and now, the evolution continues with the advent of 11-axis machining. In this article, we delve into the nuances of high precision part finishing and explore the distinct advantages offered by 11-axis machining over its 5-axis counterpart.

Understanding High Precision Part Finishing

High precision part finishing involves the intricate process of refining components to exact specifications, ensuring dimensional accuracy, surface finish quality, and overall performance. This meticulous craftsmanship is vital across diverse industries, including aerospace, automotive, medical devices, and beyond, where precision is non-negotiable.

5-Axis Machining: A Step Forward

5-axis machining revolutionized manufacturing by enabling simultaneous movement of the cutting tool along five axes, allowing for enhanced complexity and flexibility in part production. This technology excels in sculpting intricate geometries and contours with remarkable accuracy, reducing setup time and increasing efficiency compared to traditional 3-axis machining.

The Emergence of 11-Axis Machining and Beyond

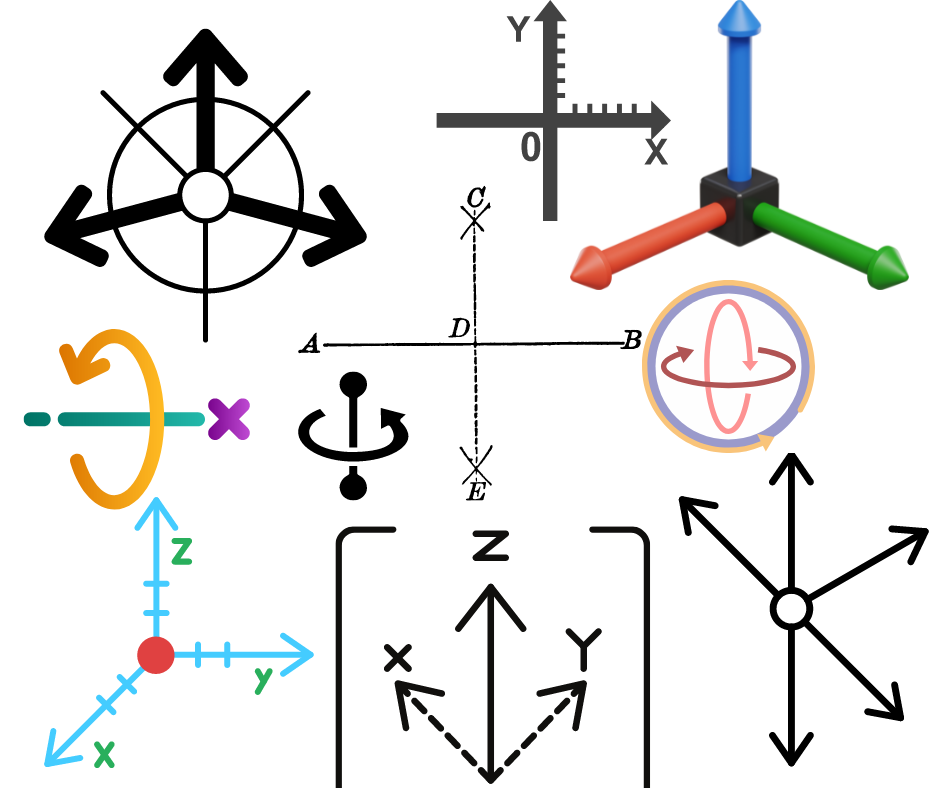

Building upon the capabilities of 5-axis machining, Multi-axes machining represents the next frontier in precision manufacturing. By incorporating additional rotational and tilting axes, this advanced technology introduces unprecedented levels of versatility and precision to part finishing processes.

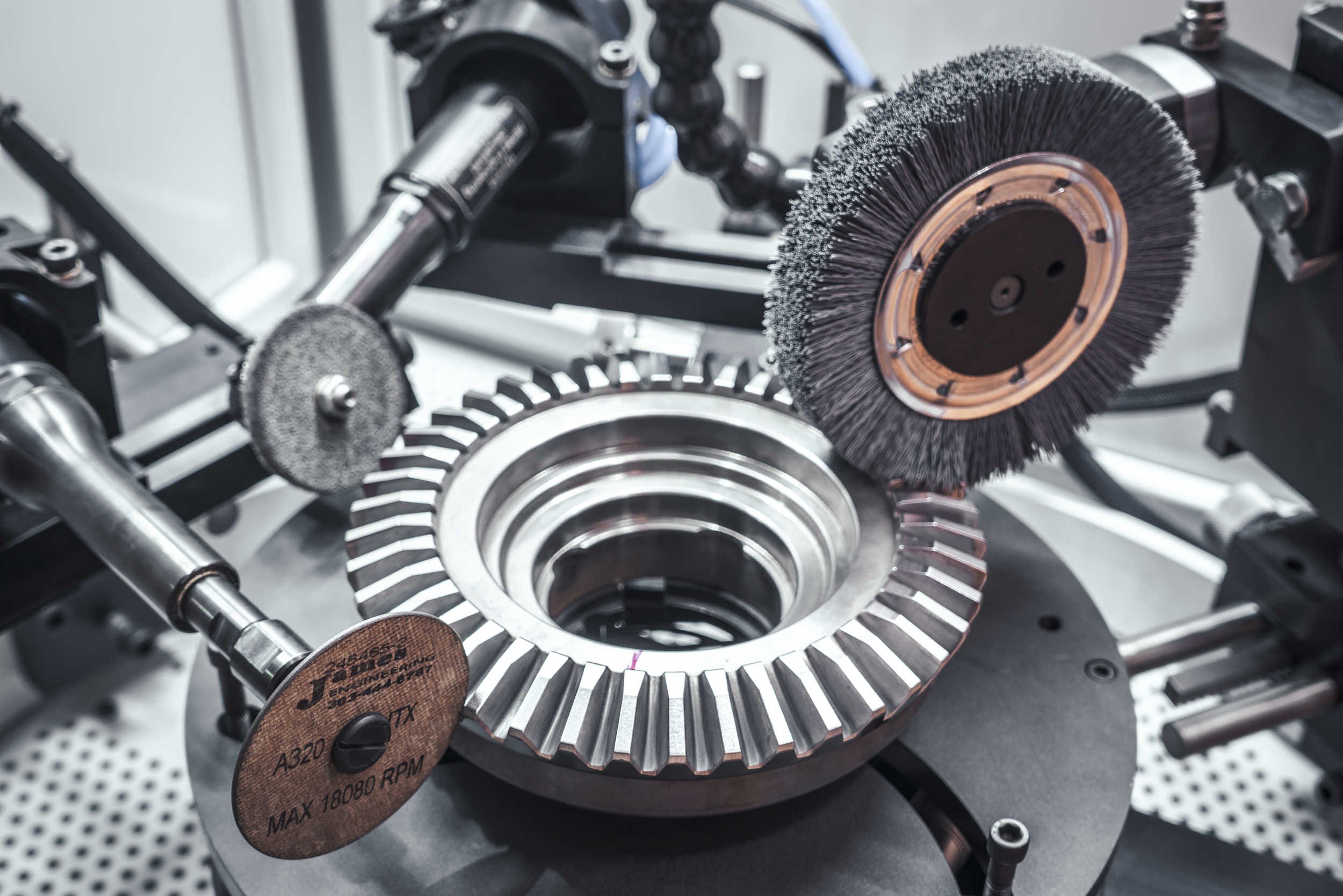

Experience precision in action with James Engineering’s state-of-the-art 11-axis 2 Tower , The MAX, all purpose finishing machine – revolutionizing part finishing for top-tier quality and efficiency.

Benefits of 11-Axis Machining over 5-Axis

Enhanced Complex Geometry Machining: With six additional axes at its disposal, 11-axis machining offers unparalleled freedom in maneuvering the cutting tool around complex part geometries. This capability is particularly advantageous for producing intricate components with challenging features, such as undercuts, draft angles, and compound curves.

Optimized Surface Finish: The increased flexibility of 11-axis machining enables precise control over tool paths and cutting angles, resulting in superior surface finish quality. Fine details and delicate features can be meticulously refined, eliminating the need for secondary finishing operations and reducing overall production time.

Improved Tool Accessibility: Complex part geometries often present challenges in tool accessibility during machining. 11-axis machines address this issue by enabling dynamic tool positioning from multiple angles, ensuring optimal reach and coverage across the entire workpiece. This capability minimizes the need for repositioning and mitigates the risk of tool interference, enhancing overall process efficiency.

Streamlined Setup and Fixturing: By reducing the reliance on elaborate fixturing and setup arrangements, 11-axis machining simplifies the preparation process for part finishing. The increased range of motion allows for more flexible workholding solutions, optimizing workflow and reducing setup time and associated costs.

Enhanced Productivity and Cost Efficiency: The precision and efficiency afforded by 11-axis machining translate into tangible benefits for manufacturers. By minimizing material waste, improving cycle times, and reducing the need for secondary operations, this technology streamlines production workflows and enhances overall productivity while maintaining competitive pricing.

The Future of Machining

In the pursuit of precision manufacturing, the transition from 5-axis to Multi Axis machining represents a significant leap forward. By unlocking new levels of versatility, accuracy, and efficiency in part finishing processes, Multi-Axis machining empowers manufacturers to push the boundaries of innovation and meet the exacting demands of modern industries. As this technology continues to evolve, its transformative impact on precision manufacturing will undoubtedly shape the future of the industry, driving advancements in product quality, performance, and competitiveness.

Contact James Engineering on how multi-axis machining can improve your cnc manufacturing process. Sales@James-Engineering.com

Mastering Precision: A Comprehensive Guide to Overcoming Part Finishing Challenges

In the intricate realm of manufacturing, achieving precision in part finishing is an ongoing pursuit that directly influences the quality and functionality of the final product. This comprehensive guide explores the common challenges encountered in part finishing and offers valuable insights into overcoming these hurdles with the help of advanced deburring and chamfering machines.

In the intricate realm of manufacturing, achieving precision in part finishing is an ongoing pursuit that directly influences the quality and functionality of the final product. This comprehensive guide explores the common challenges encountered in part finishing and offers valuable insights into overcoming these hurdles with the help of advanced deburring and chamfering machines. Let's embark on a journey to master precision in part finishing.

1. Unwanted Burrs and Sharp Edges

Challenge:

Unwanted burrs and sharp edges can compromise functionality and aesthetics.

Solution: Unwanted burrs and sharp edges can be effectively removed through various methods. Manual tools like files, abrasive brushes, and rotary deburring tools offer precision, while techniques such as abrasive blasting, chemical deburring, and thermal methods provide automated solutions. Advanced approaches like electrochemical deburring, cryogenic methods, waterjet cutting, and laser deburring cater to specific needs, emphasizing the importance of selecting the most suitable method based on material, part complexity, and production requirements.

Additional Insights:

2. Inconsistent Surface Finish:

Challenge:

Achieving a consistent surface finish is crucial for quality standards.

Solution: Achieving a consistent surface finish is crucial for quality standards because it directly impacts the appearance, functionality, and performance of a finished product. Consistency ensures uniformity in texture and appearance, which is especially important in industries where aesthetics matter, such as automotive, aerospace, or consumer electronics. Additionally, a consistent surface finish is indicative of precision and attention to detail in manufacturing processes, reflecting a higher level of quality and meeting the stringent standards expected by customers and industry regulations. In applications where friction, wear, or corrosion resistance are critical factors, a uniform surface finish is essential for optimal performance and longevity of the final product. Overall, consistency in surface finish contributes to the reliability, durability, and overall quality of the manufactured components or products.

Additional Insights:

Multi-axis deburring and chamfering machines, like the 11-Axis MAX provide control for a uniform finish, meeting specifications.

Large Batch Consistency: Guarantees uniformity even in high-volume production.

As well as the flexibility to run one off pieces.

3. Material Compatibility:

Challenge:

Diverse materials require tailored approaches for consistency.

Solution: Versatile machines handle various materials, ensuring adaptability and consistent finishing.

additional insights

Material-Specific Challenges: The MAX addresses material-specific intricacies.

Transitioning Between Materials: Seamless adaptation minimizes downtime during material shifts.

4. Complex Geometries:

Challenge

Achieving uniform finishing in intricate geometries is challenging.

Solution: Advanced machines with multi-axis capabilities navigate complex shapes with precision.

additional insights

Features: The MAX’s 11-AXIS accesses intricate internal spaces efficiently unlike anything on the market.

Variable Thickness Challenges: Precision extends to variable thicknesses, overcoming challenges associated with varying thicknesses within a single part.

No Masking: Our patented Focused Deburring saves time with precision, never mask another part.

5. Efficiency and Speed:

Challenge

Meeting tight deadlines while maintaining high precision is a common struggle.

Solution: High-speed deburring machines with multi-axis control significantly reduce processing times without compromising quality.

additional insights

Rapid Job Setup: The MAX streamlines job setup processes for increased efficiency, by employing quick set up and part change out.

Adaptability to Production Changes: Flexibility allows quick adjustments to production changes. Chamfer, polish or deburr a one-off part or 1000’s of the same part. Adaptability allows various size manufactures to employ automation.

Conclusion:

In the complex landscape of part finishing, mastering precision requires overcoming various challenges. Advanced deburring and chamfering machines, exemplified by The MAX, offer practical solutions to elevate your manufacturing process. By integrating these technologies, you can navigate the intricacies of part finishing with confidence, achieving not only precision but also efficiency and sustainability. Explore the transformative potential of advanced machinery and stay ahead in the pursuit of mastering precision in manufacturing.

Contact us for more information on 11-axis machining. Sales@James-Engineering.com

The Power of 11 Axes and Focused Deburring

James Engineering’s patented 11-axis and Focused Deburring technology unlocks a whole new way of deburring that allows for unmatched mobility and repeatable precision.

11-axis deburring — Why is it significant?

3-axis and 5-axis deburring have become common practice when it comes to the essential surface finishing process. Having a machine capable of more has been nothing but a mere concept—that is, until James Engineering came along and introduced an 11-axis machine to the market.

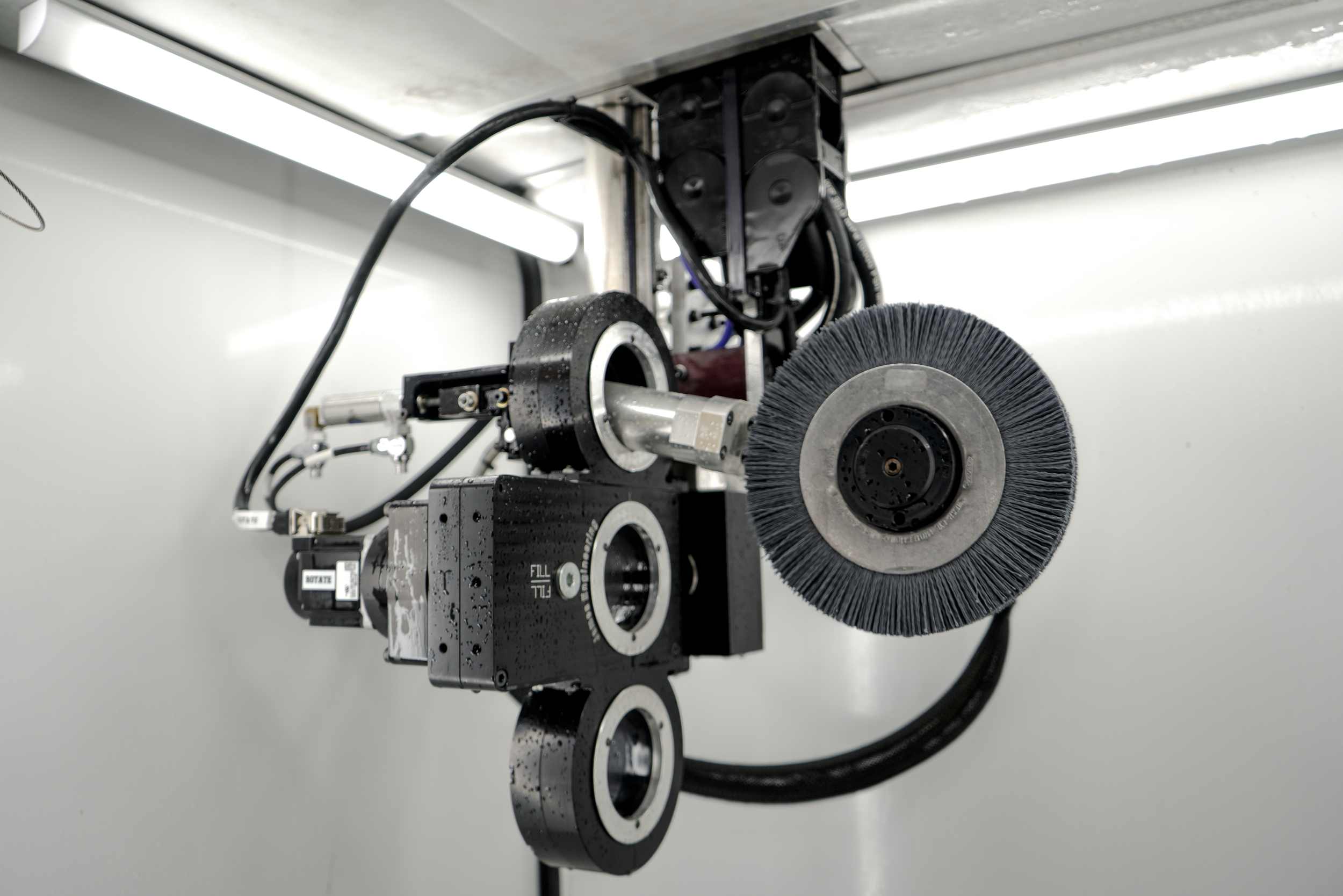

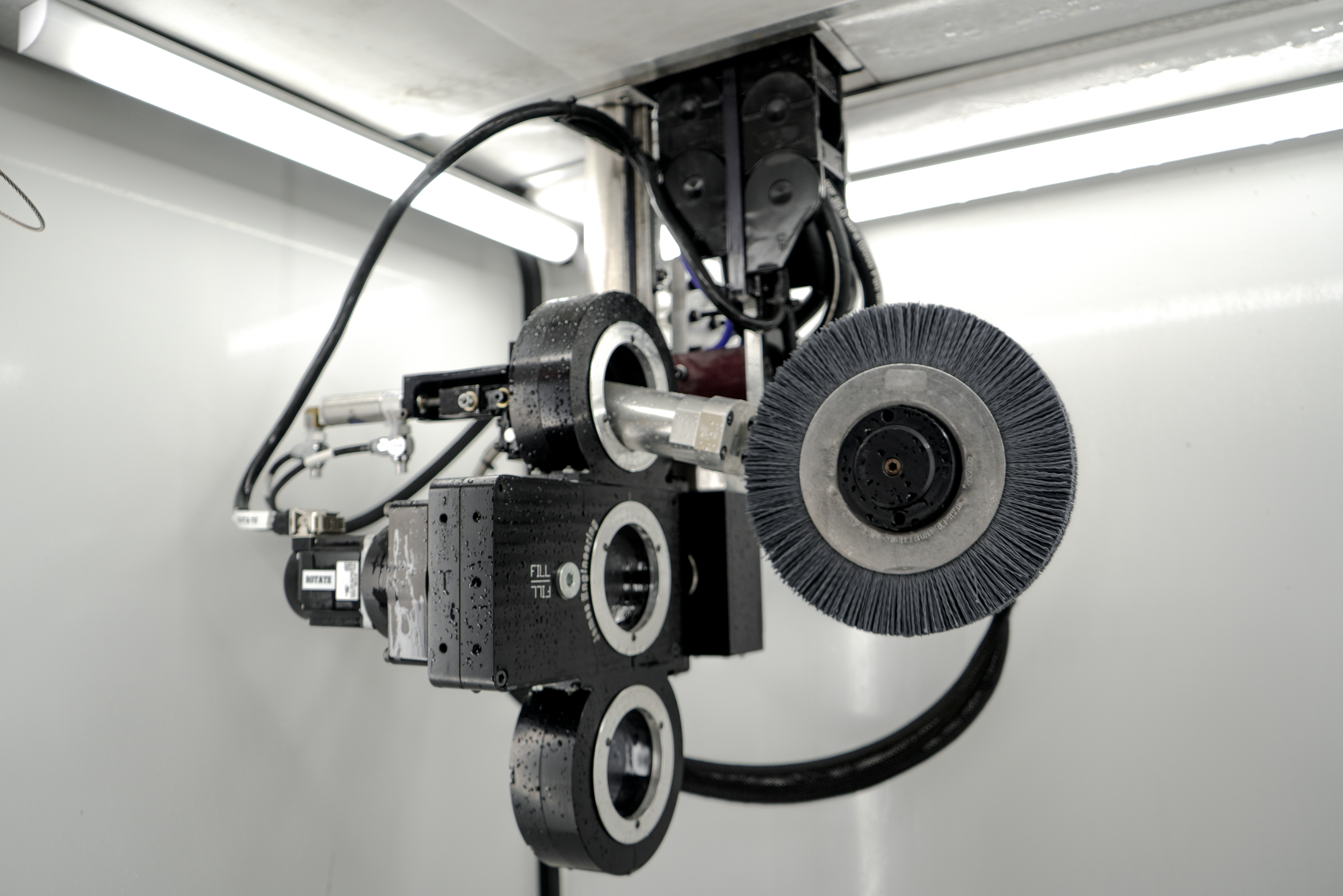

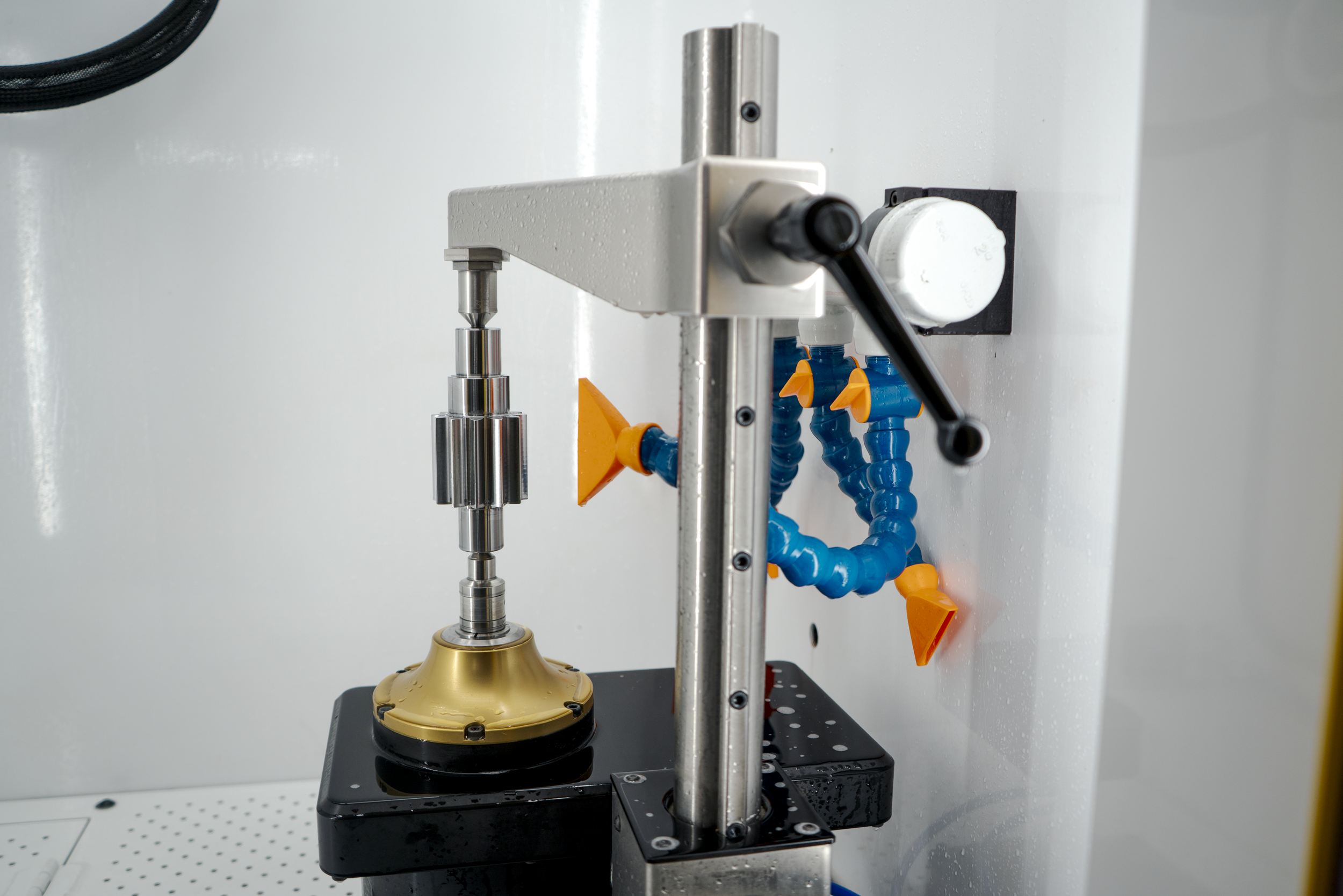

The MAX is a deburring and chamfering machine that makes 11 axes possible due to patented technologies. James Richards, the founder of James Engineering, grew exhausted constantly fixing the wear and tear on the ways and slides in his shop’s CNC machines, caused by the copious amounts of abrasive that are vital for the deburring process. So when it came to designing his own machines, made explicitly for deburring and chamfering, he installed the ways and slides on the roof instead of on the bottom of the machine. But he took it a step further when he installed a liner slide system with rolling elements. When in motion, these rollers push any harmful abrasive out of the way before it can begin to wear down the ways and slides of the machine from continued usage.

Abrasive is extremely destructive for both CNCs and robots. Measuring down to the micron level, it can easily get in between moving parts in CNCs and the rubber seals on robot joins and very quickly deteriorate their surfaces. For reference, a human hair measures up to a thousand times smaller than that of a hair. So while some may argue that CNCs are capable to handle abrasive due to its filtration system, particles that small never fully settle in washing solution when initially flushed out. This means any parts being processed in a CNC are constantly being washed with previous abrasive—an obvious problem that becomes destructive in a very short amount of time.

The MAX never has to worry about this issue. Because of this, the 11-axis system is protected and has a much longer life than any CNC or robot out there. This is especially important, as these 11 axes rely on smooth movement and mobility to work properly.

Many people prefer to deburr by hand because of precision and mobility; other methods, such as vibratory deburring, do not guarantee precision or free movement on the level that hand deburring can reach. But the problem with hand deburring is its lack of repeatable accuracy. The movement between fingers, wrist, elbow, and shoulder allow for the flexibility that’s extremely beneficial for deburring, so people have attempted to mimic this with robots. They’ve gotten pretty close, but robots lack the precision that’s paramount for deburring, making it an unreliable method. The MAX is able to combine the best elements of both—a CNC’s precision and a robot’s agility—into one. Pair that fact with its patented linear slide technology, and you’ve got a smooth and accurate machine that can reach any angle or edge without falter, and repeatably so.

Focused Deburring and how 11 axes play a part.

As mentioned before, mass deburring processes such as vibratory deburring can’t offer precision. During processes like these, the entirety of a gear or part is being touched. They can be masked, but masking cannot be done by machine and adds additional time-consuming labor to a cycle. Masking also cannot guarantee that areas of a part won’t get deburred anyway. This was yet another issue Richards set out to solve and lead him to creating Focused Deburring.

Focused Deburring requires at least 6 axes in order to work properly (the MAX has anywhere from 6-11 acis motion, depending on what model is being used), and is capable of deburring any desired area on a part/gear without touching the rest of it. The human-like motion that the MAX has makes this possible because it can move around just like an operator would in order to avoid these other areas. Then its repeatable precision comes in to play by ensuring that every single part comes out the exact same, no matter how tricky or intricate a part proves to be—reliable accuracy at its finest.

Gears are a great example of items that benefit greatly from Focused Deburring. Take a fuel pump gear, for example. These gears have high-precision journals and protruding tooth flanks, both of which rely on precision in order to be made properly. What frequently happens when these kinds of gears are deburred is the journals almost always get touched when the tooth flanks are being worked on. Operators can attempt to mask the journals, but they can still get nicked if an operator isn’t careful enough. This results in high scrap rates, wasted resources, and wasted time. With Focused Deburring, fuel pump gears can be loaded into the MAX without fear of destruction. Focused Deburring is not only limited to one type of gear or part, however; every single type of gear or part that needs deburring can be put into the MAX and come out with imperfection.

Overview

Not only is the 11-axis motion featured in the MAX an exciting change in the deburring world, but it’s also revolutionizing for every operation out there. With 11 axes, the MAX has a work envelope of 360-degrees and is capable of reaching every side of any gear or part without an operator needing to adjust it manually. It features the precision of a CNC, the mobility of a robot, and an upfraded linear slide system that makes it resistant to all abrasives. There’s not a single other machine like it on the market, and the 11-axis motion is just the tip of the iceberg. Check out the video below to see the 11 axes in action!

If you’re interested in experiencing the revolutionizing deburring machine for yourself, give James Engineering a call at (303) 444-6787, or email us at Sales@James-Engineering.com.

Part Finishing 101: A Beginner's Guide

Part finishing is an in-depth process requiring multiple different applications to ensure parts are processed to perfection.

Every piece of machinery is made up of a thousand smaller pieces all continuously working together to accomplish the same goal. Every single one of these pieces need to go through the part finishing process, which ensures they work correctly and keep the overall operation running smoothly. “Part finishing” is an umbrella term for all the individual processes and techniques that go into the ultimate completion of these parts/gears.

Machining

First, let’s start with machining. This is where gears/parts are initially manufactured out of blocks of raw material. CNC (computer numerical control) machines do most of this work, and there are multiple different kinds of CNC machines, such as milling machines, lathes and turning machines, laser cutting machines, etc. Excess material is carved away by these machines to reveal the rough shape of whatever gear/prismatic part is being created. Once this first step is completed, the nitty-gritty side of part finishing begins.

Deburring

Deburring is the process of removing burrs from the edges and surfaces of these freshly cut parts/gears. Burrs are sharp bits of excess metal that will eventually ruin the integrity and overall quality of whatever part/gear they’re stuck to. This process can be done by hand, in a CNC machine, or a machine made specifically for deburring*, such as a James Engineering machine. Deburring is one of the most crucial aspects of part finishing, as many other processes cannot be done if a part or gear is not deburred properly.

Surface Grinding

This process creates smooth surface finishes on metal and non-metal parts alike. It’s an abrasive process which uses grinding wheels to shave down any surface impurities that might affect the functionality and aesthetic of a gear/part. Grinding wheels (add link to website page here) come in a variety of sizes and materials, which directly determine a wheel’s grinding intensity. Grinding surfaces are crucial when it comes to achieving tight part tolerances, as it ensures a part will fit perfectly within its environment. Surface grinding will also rid a part/gear of any corrosive layers that may negatively affect its overall durability.

Polishing

Polishing is done to further smoothen a part’s surface. What makes polishing different from surface grinding is that it’s meant to enhance surface quality, whereas grinding is used to remove extra material. Polishing is also an abrasive process, and it uses polishing pastes and abrasive pads. Polished parts are reflective and more resistant to corrosion, which makes it a crucial step in the finishing process for items such as car bumpers, medical equipment, mirrors, and more.

Buffing

Many people get buffing and polishing confused—but it’s fair considering how alike these two processes are. What makes them different is their levels of aggression. Buffing is the more aggressive of the two, and can actually remove surface material if done too hard. It can be used to remove shallow scratches, and unlike polishing, it will not leave a highly reflective surface. Buffing is frequently used in the automotive, jewelry, and electronic industries.

Chamfering

This step of the part finishing process is extremely important, especially for pieces with right-angled edges. Chamfering is when these edges are cut at a slope, which later makes assembly easier and reduces the amount of stress risers within a gear/part. Sharp, non-chamfered edges can snap and break off, leading to loose material floating throughout a machine. This debris could ultimately affect the efficiency of the entire machine, and even cause it to fail completely. When edges are chamfered, the likelihood of such an occurrence is reduced drastically. It will also ensure that pieces fit together more snugly, reducing the risk of the parts themselves becoming too loose.

Brushing

Brushing can be categorized as a type of deburring, as it can technically get rid of excess burrs left on the surfaces of parts. But that’s not its man job—brushing is used as a way to further perfect part surfaces, as it preps parts for coatings and rids them of any external contaminants, such as oils, dirt, residue, etc. It is also a very precise process in the sense that if only one small section of a part/gear needs further surfacing, a brush can stay focused on that specific spot without affecting the rest of the gear/part’s body. An important thing to remember when it comes to metal brushing is that certain brushes must be used on certain metals; for example, stainless steel can only be brushed with steel brushes. But other materials, such as rubber and leather, can also be brushed if need be.

Sandblasting

This process is also known as abrasive blasting, as it can be done with many other substances other than sand, such as glass beads, water, dry ice, and compressed air. This is another technique used to smoothen, decontaminate, and shape surfaces. This technique of part finishing comes from the naturally occurring phenomenon called aeolian erosion, which is when an environment’s geography is changed and shaped by consistent winds. Blasting is done manually when a blasting substance is mixed with air in a pressurized chamber and dispensed through an abrasive-proof handheld nozzle.

Washing

The washing process works exactly how you’d think it would—a mixture of hot water, solvent, or washing fluid are dispensed either by hand or by a machine over freshly-processed parts to clean them of excess swarf. It’s important to wash parts of debris because, as mentioned above, debris can drastically decrease the effectiveness of a part/gear and the greater machine it was assembled into. In order to avoid corrosion or rusting, special fluids must be used to protect both the part being washed and the machine doing said washing.

Overall

Machining, deburring, chamfering, washing, brushing, surface grinding, polishing, buffing, and sandblasting are the most common part finishing processes in the manufacturing industry, but there are still a variety of methods used that were not mentioned. Each process has its own unique use, and it’s crucial that manufacturers understand what method will produce the strongest outcome for a part or gear.

How James Engineering Part Finishes

Here at James Engineering, we are experts when it comes to the varying methods of part finishing. We manufacture and sell all all-encompassing surface finishing and chamfering machine known as the MAX System, and it’s got you covered completely—the MAX can deburr, chamfer, wash, brush, and even radius parts/gears of various sizes. The best part is the MAX can carry out multiple processes at once, which exponentially cuts down on processing time and leads to a higher production volume.

If you’d like to experience the effortless efficiency of a multitasking finishing fiend, contact us at Sales@James-Engineering.com and we will send you a quote!

*For being such a vital part in the finishing process, deburring machines are an extremely niche market of their own. James Engineering specializes in deburring and chamfering machines and offers a variety of systems at competitive pricing. Click here to learn more about the different kind of systems we manufacture.

The Dynamic Duo

Why a CNC machine and the MAX System make the perfect pair.

As the demand for parts grows exponentially within the manufacturing industry, so does the need for expert deburring and chamfering. James Engineering manufactures an all-purpose finishing system known as the MAX System that is meant to be paired with CNC machines to produce parts of the highest caliber.

“The MAX is meant to compliment CNC machines,” explains Scott Richards, Vice President of James Engineering. “The MAX allows CNC machines to do what they do best: make parts.”

While CNC machines can deburr parts, they tend to be choppy, aggressive, and slow at it; their primary function is to cut. This means high-volume shops are extremely limited when it comes to both the quality and quantity of parts they’re producing (that is if they rely on CNC machines to deburr as well). The MAX is the solution to this problem—it leaves cutting to the CNC machines and does everything else. “We’re not trying to make a metal cutting machine, or a part manipulator. We’re making a machine that does a delicate job quickly in a way that hand deburring, and CNC machines, can’t,” says Richards. So once the CNC machines can focus solely on cutting, a higher volume of parts can be produced in one day, ultimately heightening a company’s productivity as well as increasing their overall part quality.

Not only does the MAX make overall processing easier, but the machine itself is easily operatable, especially for those who have prior experience with CNC machines. “Within four minutes anybody could learn how to use the machine,” Richards states, “We teach these machines to move into position conversationally, have it catch that point, then move to another position. This is unlike CNC machines, or even robots. If someone new wanted to run a CNC machine, they’d have to understand the language the program is written in; we do not run M- or G-code, we use conversational programming.”

Deburring in a CNC machine can be inaccurate and slow-moving—but that’s because deburring isn’t the main function of a CNC, cutting is. The whole purpose of the MAX is to take the weight of deburring off CNC machines. So while the CNCs focuses on expertly cutting parts, the MAX deburrs, chamfers, brushes, washes, and surfaces all in one go after said parts have gone through the CNC. The MAX will pick up a CNC’s slack, and vice versa, making them the perfect pair. The duo will drastically reduce cycle times while still producing a high volume of expertly processed parts with focus, and without the sacrifice of integrity. For any shops out there running into issues with CNC deburring, or for companies who would simply like to increase their productivity overall, investing in the MAX is the next step you need to make.

Everyone needs a best friend, even machines. Give your CNC its best buddy today and inquire at Sales@James-Engineering.com as to how you can bring your MAX home.