The Chamfer Machine Unmatched by All

Gear chamfer machine manufacturers who make an automatic chamfer machine may succeed at efficiency, precision, or sustainability but finding an optimized solution of all three advantages remains elusive. Until now

Chamfer Machine Manufacturers

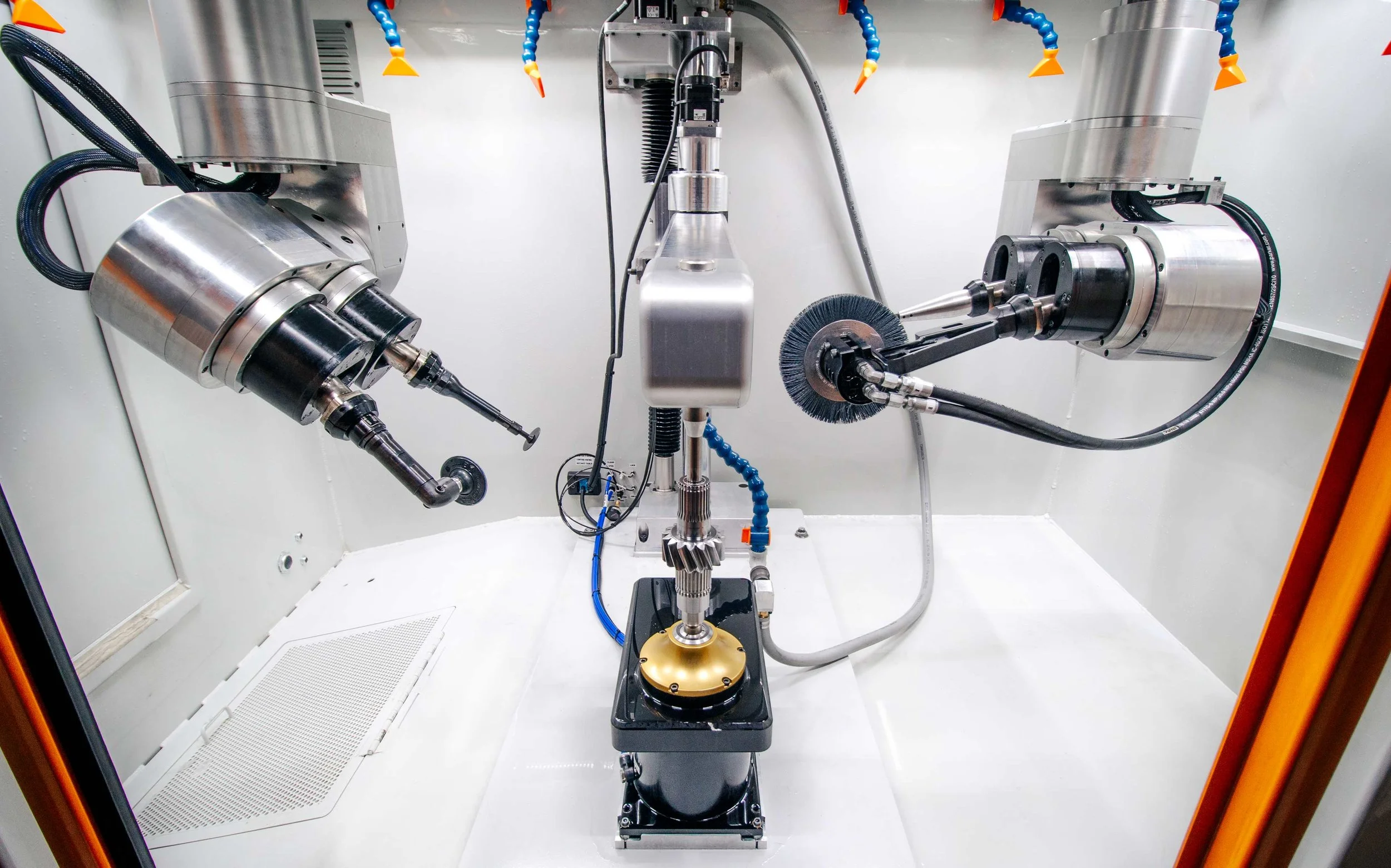

Automated Chamfer machine manufacturers who make an automatic chamfer machine may succeed at efficiency, precision, or sustainability but finding an optimized solution of all three advantages remains elusive. That however is where the all-purpose MAX System Machine by James Engineering comes in. The MAX System Machine is not just another chamfering tool; it represents a shift in machining technology. Designed to deliver unmatched performance across multiple fronts, the MAX System Machine redefines what is possible in chamfering operations. Not only does it provide a repeatable precision chamfer, but its versatility extends to accommodating an unlimited array of tool heads meant for deburring, polishing, radiusing, other finishes, and more.

Changing Industrial Manufacturing

The reason James Engineering’s machines reach such a high level of optimization could be attributed to their commitment to being a full OEM manufacturer. By producing all components of the machine in-house, James Engineering holds complete control over every feature, ensuring maximum performance and reliability. This also allows for the creation of flexible machines that fit the needs of any customer. Every machine aspect can be configured to optimize any operation.

Efficiency

Efficiency is at the core of the MAX System Machine's design. James Engineering's multi-tool machines are engineered to perform tasks quickly and simultaneously, minimizing cycle times and maximizing productivity. For example, the MAX System M5W consists of two 5-axis overhead servos with two interchangeable tools each. They perform operations simultaneously on a c-axis rotary table, making this a 4-tool 11-axis machine. James’ machines have chamfered and deburred 82 gear teeth on a part in just 30 seconds, including secondary burrs. However, companies love to talk about quick cycle times but are quiet regarding change-out time in between the cycles. James Engineering surpasses this norm of slow downtimes by achieving efficiency that extends beyond cycle speeds. By eliminating setup time and maintaining a saved log of cycles, James Engineering enables seamless transitions for running multiple parts or simply with the push of a button repeating the same part. Each machine is designed with a user-friendly control panel allowing for any operator to run them, regardless of experience. James Engineering also offers fully automated “lights out” machines that require no human operator to run parts, further streamlining operations.

Precision

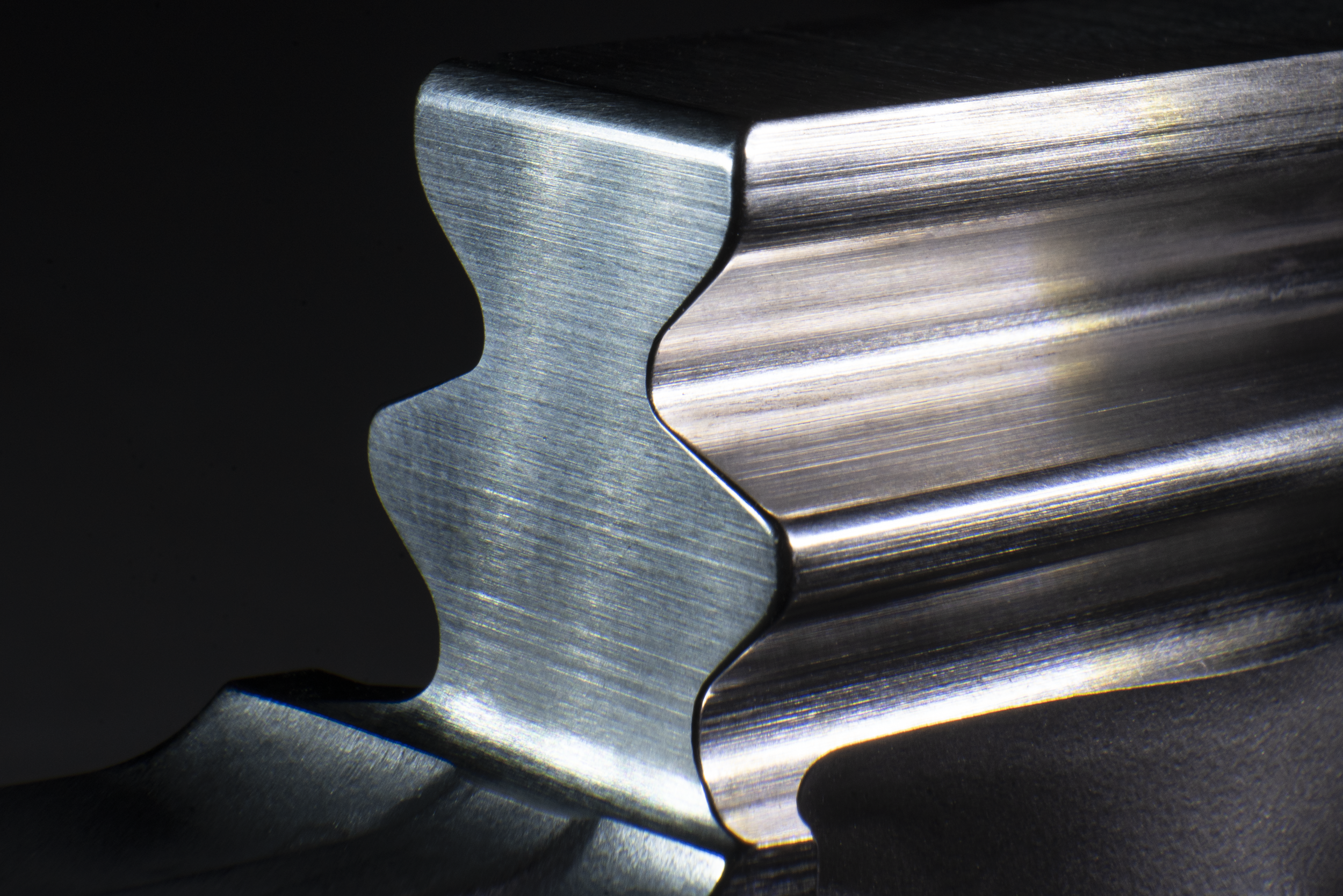

Precision is another area where the MAX System Machine stands out. With consistent radiuses and cutting-edge compliant technology, James Engineering sets a new standard for precision chamfering. Unlike conventional machines that may struggle with unpredictable variables such as wheel wear or part inconsistencies, the MAX System Machine's patented compliant technology ensures consistent results every time, regardless of external factors. With a huge gain in efficiency, there is no loss in precision, there is quite the opposite. Even on small micro-parts, there is a visual difference when the part is finished on a James Engineering machine. Intricate and oddly shapen parts are also still finished with perfect chamfers and radiuses. These precision finishes minimize part wear and stress points to the fullest extent.

Sustainability

Sustainability is a must in modern manufacturing, and the MAX System Machine delivers on this as well. Programmable cycles, which can be saved as "recipes," ensure perfect cycles every time, eliminating scraped parts and optimizing resources. With optional “wet” cycles, these MAX System machines are equipped with a 150-gallon tank that is filtered and recycled into the next cycle, maximizing the use of the water. Additionally, James Engineering produces their own grinding wheels with a liquid resin that extends part life and promotes even wear. Paired with compliant technology, that won’t over-engage tools, the life of the grinding wheels and various tool heads is greatly extended, further enhancing sustainability efforts.

An Automatic Chamfer Machine like no other

The MAX System Machine by James Engineering remains an industry leader in chamfering and finishing technologies, continuing to advance the manufacturing process. By seamlessly integrating efficiency, precision, and sustainability into a single, innovative solution, the MAX System Machine allows manufacturers to elevate their chamfering and finishing operations to new heights of performance and excellence.

If you’d like to know more reach out and learn how James Engineering can upgrade and take your manufacturing process to the next level. Watch our machine in operation below and see our technologies in action.

What Is Gear Chamfering?

In simple terms, gear chamfering is the process of cutting a 90-degree edge at a 45-degree angle, but in reality it’s a bit more complicated than that.

Simply put, the process of chamfering is cutting a 90-degree edge at a 45-degree angle as a way to remove stress-rising sharp edges, as well as allow for smoother assembly. That makes chamfering sound easy, when in reality it’s actually very time consuming, no matter the method of approach.

Gear Chamfering can truly be broken down into four separate surface-finishing processes: deburring, chamfering, radiusing, and radius-chamfering.

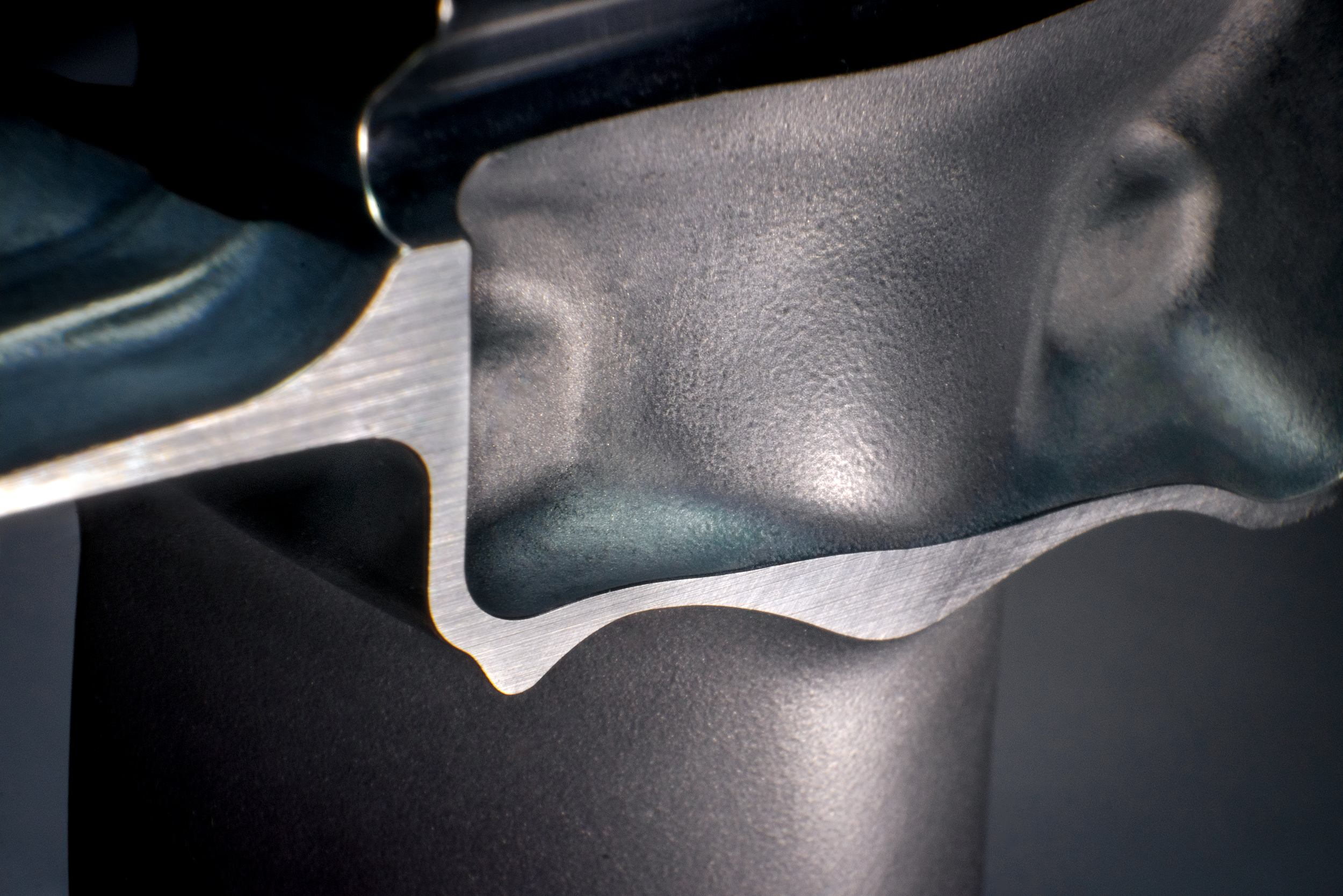

- Deburring is the process of grinding off burrs, which are bits of excess metal created in the metal cutting process. Burrs are extremely problematic and will cause issues in assembly as well as overall part efficiency. Assuming the deburring has been done properly, all burrs will have been completely removed, leaving nothing but a sharp edge.

- Chamfering, as stated above, is the process of cutting that sharp edge at a 45-degree angle (which is the most common angle, but not the only one they’re limited to). Chamfering can be done with a myriad of tools, such as brushes, sandpaper, grinding wheels, and Scotch-Brite. However, in the process of shaving down this one sharp edge, two more are created on either side of the original, and if the tool being used is worn down, burrs can be created as well.

- Radiusing is the process of completely rounding out edges until it’s completely smooth. While chamfering is smoother than just leaving a part deburred, it still is cut at a noticeable angle that can be seen and felt. Radiusing feels and looks rounded (just like how a ball is round without any hard edge), and can also be carried out via brushes, grinding wheels, and sandpaper. It’s crucial to know what materials these tools are made out of, because the materials will affect the quality of the radius; if a material is too abrasive, it will be impossible to reach a true radius. A true radius is when the edges of a 90-degree angle go tangent to tangent without any surface imperfection.

- Radius-chamfering is when a part receives both radiusing and chamfering. The sharp angle is cut at the usual 45-degree angle, and when those two extra sharp angles are created, they are radiused to create smooth transitions between chamfers.

When it comes to how chamfering is done, there’s a few methods operators can choose from—machine-based, hand-based, or robot-based.

Different types of gear chamfering machines are capable of different sub-categories of chamfering. For example, a CNC machine can decently deburr a part, a lathe can adequately radius-chamfer a part, and a mill can chamfer a part. All of these options are valid, but not a single one of them can chamfer, deburr, and radius a part; separate machines are needed. Not only that, but these kinds of machines require in-depth programming for every single part in order to be exact. The MAX by James Engineering is capable of carrying out all four chamfering processes with heightened precision, as well as little programming.

Doing any of these processes by hand is technically achievable, but it ultimately proves to be more troublesome than it’s worth. Manufacturing is an industry that requires precision, as things will fall apart and fail to work correctly without it, and doing these processes by hand simply does not provide adequate enough precision. Even the best operator can slip or tremble, and man cannot repeatably guarantee a consistent chamfer. Hand chamfering is acceptable in a pinch, especially if only one or a handful of parts require it. But for higher volume operations, not only does hand chamfering not produce consistent results, it also is extremely time and cost inefficient. Scrap rates are the highest with hand chamfering, and the time it takes operators to complete one part is what it would take a CNC to do two or three, or the MAX to do a hundred.

Robots are only slightly better at gear chamfering than when done by hand. While they do have better mobility than most machines, they lack precision. Robots are perfect for operations that require the moving and placing of items, but they just cannot match a machine’s precision. Robots also require a lot of laborious programming, overall making them a poor method of chamfering.

Out of all these methods, the MAX is hands down the most reliable and efficient. As an all-encompassing finishing system, it is capable of deburring, chamfering, radiusing, and radius-chamfering any part or gear, no matter its complexity. It does require some initial programming, but once a part/gear has been loaded in, the MAX will remember it for future use, meaning operators no longer have to manually input adjustments themselves (James Engineering calls these programs “recipes”). The MAX is also capable of repeatable precision down to the fifth decimal. For reference, the average human hair measures to .003 inches. The MAX can repeatably work down to .00001 inches, and even beyond that.

Precision in chamfering is key, because the less precise a chamfer is, it’s more likely that stress risers will appear with continual usage. Stress risers are tiny cracks that form at a part/gear’s weakest point of contact (like the tooth on a gear). If a part is not adequately deburred or chamfered, what will happen is those sharp edges will slowly break off until a part or gear’s structure is ultimately compromised. So that previously mentioned tooth could fall off, for instance. That is extremely dangerous, both for the assembly itself and the people operating it. For example, a helicopter would crash if one of the gears in its motor failed. When it comes to chamfering, the higher the precision, the better. The precision achieved by the MAX means that parts/gears processed through it are extremely unlikely to form stress risers even after years of use.

There’s a misconception about chamfering that it’s done easily. Even with an advanced machine such as the MAX, chamfering is no “easy” feat. If a chamfering operation appears to be “easy”, it’s probably being done sloppily and inefficiently—and precision takes time and effort.

Knowing the correct way to chamfer is a gamechanger with any operation, as well as being able to recognize when a chamfer is done correctly. If it is, parts will fit together with no resistance and work efficiently for the entirety of their lifetime. And when parts work correctly, overall assemblies will perform at their best.

To visibly see how chamfering is done, watch a short video clip here.

To contact James Engineering about the MAX’s chamfering abilities, call at (303) 444-6787