The Power of Compliant Technology, the Magic Behind The MAX

There’s major problem in the industry! Find out how we solve it!

See how James Engineering is solving the problem of non-inform parts , watch the video below

Precision is key.

Yet, the reality often falls short of the ideal, with parts turning out to be anything but perfect. Scott Richards, Vice President of James Engineering, delves into the heart of this challenge, shedding light on the industry's persistent problem and the innovative solution James Engineering has developed.

Solving the Problem of Non-Uniform Parts

Watch below as Scott Richards opens the discussion by addressing a common yet critical issue in manufacturing: non-uniformity. Many parts, despite appearing round, lack uniformity in dimensions. This discrepancy poses a significant challenge, particularly in processes like deburring, where precision is paramount.

Traditional approaches, including vision systems and CNC machines with complex algorithms, have failed to adequately address this issue over the past four decades. However, James Engineering's breakthrough compliant technology offers a revolutionary solution.

The Essence of Compliant Technology

Compliant technology mimics the human hand's ability to sense and adapt to surfaces in real-time. Unlike conventional methods reliant on lasers or mathematical equations, compliant technology mechanically senses and reacts to surface variations as they occur. This approach eliminates the need for predictive algorithms and ensures consistent results, even with perishable tools prone to uneven wear.

Navigating the Challenges of Inconsistent Parts

Watch as Scott delves deeper into the complexities of inconsistent parts, emphasizing the significant impact of stress relief in machining processes. As parts undergo machining, stress relief can cause unexpected distortions, leading to mismatches between the intended model and the final product. This disparity poses challenges for CNC machines and robots programmed to expect uniformity.

Addressing the Inconsistency

James Engineering's compliant technology offers a versatile solution to address inconsistencies across various manufacturing processes. By dynamically adjusting to surface variations, the technology ensures precise results, regardless of a part's shape or dimensions. Unlike traditional methods reliant on human intervention, compliant technology offers unparalleled accuracy and repeatability, enhancing overall manufacturing efficiency.

Empowering Manufacturers with Precision

In a competitive manufacturing landscape, precision is non-negotiable. James Engineering's compliant technology empowers manufacturers to achieve unparalleled precision and consistency, revolutionizing traditional manufacturing processes. By eliminating the reliance on manual intervention and predictive algorithms, the technology streamlines operations, reduces costs, and enhances product quality.

Embracing the Future of Manufacturing

As industries evolve and technology advances, embracing innovative solutions becomes imperative for sustained success. James Engineering's compliant technology represents a paradigm shift in manufacturing, offering a glimpse into the future of precision engineering.

Scott Richards's insights into the transformative potential of compliant technology underscore its significance in revolutionizing manufacturing. By bridging the gap between traditional methods and emerging challenges, James Engineering paves the way for a new era of precision and efficiency in manufacturing.

Incorporating compliant technology into manufacturing processes holds the promise of unlocking new possibilities and driving unprecedented levels of efficiency and precision. As industries continue to evolve, embracing such innovations will be crucial for staying ahead of the curve.

The Advantage of 11-Axis Machining over 5-Axis Machining in High Precision Part Finishing

In the realm of manufacturing, precision is paramount. Achieving high precision in part finishing not only enhances the quality of the final product but also significantly impacts efficiency and cost-effectiveness. Traditional machining methods have paved the way for advanced technologies like 5-axis machining, and now, the evolution continues with the advent of 11-axis machining. In this article, we delve into the nuances of high precision part finishing and explore the distinct advantages offered by 11-axis machining over its 5-axis counterpart.

In the realm of manufacturing, precision is paramount. Achieving high precision in part finishing not only enhances the quality of the final product but also significantly impacts efficiency and cost-effectiveness. Traditional machining methods have paved the way for advanced technologies like 5-axis machining, and now, the evolution continues with the advent of 11-axis machining. In this article, we delve into the nuances of high precision part finishing and explore the distinct advantages offered by 11-axis machining over its 5-axis counterpart.

Understanding High Precision Part Finishing

High precision part finishing involves the intricate process of refining components to exact specifications, ensuring dimensional accuracy, surface finish quality, and overall performance. This meticulous craftsmanship is vital across diverse industries, including aerospace, automotive, medical devices, and beyond, where precision is non-negotiable.

5-Axis Machining: A Step Forward

5-axis machining revolutionized manufacturing by enabling simultaneous movement of the cutting tool along five axes, allowing for enhanced complexity and flexibility in part production. This technology excels in sculpting intricate geometries and contours with remarkable accuracy, reducing setup time and increasing efficiency compared to traditional 3-axis machining.

The Emergence of 11-Axis Machining and Beyond

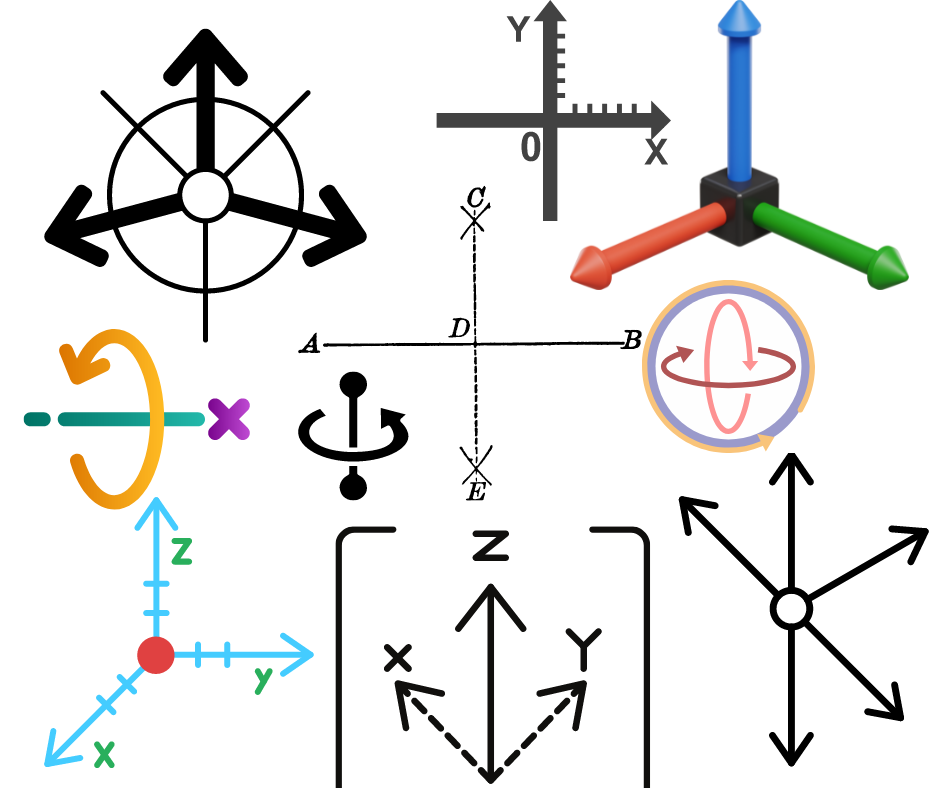

Building upon the capabilities of 5-axis machining, Multi-axes machining represents the next frontier in precision manufacturing. By incorporating additional rotational and tilting axes, this advanced technology introduces unprecedented levels of versatility and precision to part finishing processes.

Experience precision in action with James Engineering’s state-of-the-art 11-axis 2 Tower , The MAX, all purpose finishing machine – revolutionizing part finishing for top-tier quality and efficiency.

Benefits of 11-Axis Machining over 5-Axis

Enhanced Complex Geometry Machining: With six additional axes at its disposal, 11-axis machining offers unparalleled freedom in maneuvering the cutting tool around complex part geometries. This capability is particularly advantageous for producing intricate components with challenging features, such as undercuts, draft angles, and compound curves.

Optimized Surface Finish: The increased flexibility of 11-axis machining enables precise control over tool paths and cutting angles, resulting in superior surface finish quality. Fine details and delicate features can be meticulously refined, eliminating the need for secondary finishing operations and reducing overall production time.

Improved Tool Accessibility: Complex part geometries often present challenges in tool accessibility during machining. 11-axis machines address this issue by enabling dynamic tool positioning from multiple angles, ensuring optimal reach and coverage across the entire workpiece. This capability minimizes the need for repositioning and mitigates the risk of tool interference, enhancing overall process efficiency.

Streamlined Setup and Fixturing: By reducing the reliance on elaborate fixturing and setup arrangements, 11-axis machining simplifies the preparation process for part finishing. The increased range of motion allows for more flexible workholding solutions, optimizing workflow and reducing setup time and associated costs.

Enhanced Productivity and Cost Efficiency: The precision and efficiency afforded by 11-axis machining translate into tangible benefits for manufacturers. By minimizing material waste, improving cycle times, and reducing the need for secondary operations, this technology streamlines production workflows and enhances overall productivity while maintaining competitive pricing.

The Future of Machining

In the pursuit of precision manufacturing, the transition from 5-axis to Multi Axis machining represents a significant leap forward. By unlocking new levels of versatility, accuracy, and efficiency in part finishing processes, Multi-Axis machining empowers manufacturers to push the boundaries of innovation and meet the exacting demands of modern industries. As this technology continues to evolve, its transformative impact on precision manufacturing will undoubtedly shape the future of the industry, driving advancements in product quality, performance, and competitiveness.

Contact James Engineering on how multi-axis machining can improve your cnc manufacturing process. Sales@James-Engineering.com