Mixed and Rare Metal Finishing

Mixed and Rare Metal Finishing: Deburr Techniques and Benefits

While many metals are straightforward to machine using standard equipment, mixed and rare earth metals possess unique chemical properties that necessitate specialized machining processes.

Understanding Mixed Metals and Why Finishing Mixed and Rare Metals Requires Specialized Techniques, Surface Finishing

Mixed and Rare Metal Finishing: Techniques and Benefits

Machine metal processing is a crucial part of manufacturing, where metal parts are transformed through alterations in shape, dimensions, properties, and finishes to create finished products. While many metals are straightforward to machine using standard equipment, mixed and rare earth metals possess unique chemical properties that necessitate specialized machining processes.

Understanding Mixed Metals

Mixed metals, also known as alloys, are combinations of two or more metals that result in enhanced properties. Here are some common mixed metals, their properties, and applications:

Brass: Known for its malleability and ease of cold and hot forming, brass is used in keys, connectors, radiators, and musical instruments.

Bronze: Appreciated for its corrosion resistance and strength, bronze is ideal for gears, pumps, diaphragms, and architectural fittings.

Copper: Renowned for its ductility and conductivity, copper is extensively used in electrical wiring, semiconductors, and antimicrobial surfaces.

The Role of Rare Earth Metals

Rare earth metals, a group of 17 elements, are not rare in abundance but are seldom found in economically viable concentrations. Their unique properties make them irreplaceable in certain applications, despite their processing challenges.

Notable Rare Metals and Their Uses

Magnesium: Lightweight and strong, magnesium is used in laptop enclosures, automotive transmissions, and small electronics.

Zirconium: With exceptional resistance to hydrochloric acid and ease of welding, zirconium finds use in nuclear reactors, pumps, and chemical processing equipment.

Titanium: Strong, corrosion-resistant, and biocompatible, titanium is essential in medical implants, aerospace components, and high-performance automotive parts.

Finishing Methods for Mixed and Rare Metal Parts

Finishing methods for rare and mixed metal parts and gears are crucial to enhance their performance, durability, and aesthetics. Here are some commonly used finishing techniques:

Electroplating: Applying a thin layer of metal onto the surface of the part using an electric current. This can improve corrosion resistance, reduce friction, and enhance appearance.

Anodizing: An electrochemical process that converts the metal surface into a durable, corrosion-resistant oxide layer. This is particularly common for aluminum parts.

Passivation: Treating metal with an acid solution to remove contaminants and enhance the formation of a protective oxide layer, especially useful for stainless steel parts.

Heat Treatment: Heating and cooling the metal to alter its physical and mechanical properties, such as hardness and strength.

Powder Coating: Applying a dry powder that is then cured under heat to form a protective and decorative layer. This provides a durable and high-quality finish.

Grinding: Using abrasive wheels to remove material and achieve a smooth surface with precise dimensions. This is commonly used for gears to ensure proper meshing and function.

Polishing and Buffing: Mechanical processes that use abrasives to create a smooth, reflective surface. Polishing removes minor imperfections, while buffing produces a high-gloss finish.

Shot Peening: Bombarding the surface with small spherical media to induce compressive stresses, improving fatigue resistance and reducing the risk of stress corrosion cracking.

Laser Cladding: Using a laser to melt and fuse a coating material onto the surface of the part, providing enhanced wear and corrosion resistance.

Chemical Vapor Deposition (CVD): Depositing thin films of material onto the surface through chemical processes, providing excellent hardness and corrosion resistance.

Physical Vapor Deposition (PVD): Depositing thin films of material through physical processes, such as sputtering, to achieve superior hardness and wear resistance.

Electropolishing: An electrochemical process that removes a thin layer of material to achieve a smooth, shiny finish and improve corrosion resistance.

Vibratory Finishing: Placing parts in a vibrating container with abrasive media to deburr, clean, and polish the surfaces.

Why Finishing Mixed and Rare Metals Requires Specialized Techniques

Finishing mixed and rare metals is particularly challenging due to their unique chemical and physical properties. These metals often have high strength, hardness, and corrosion resistance, which can make them difficult to machine and finish using standard techniques. The diverse compositions of mixed metals (alloys) can lead to varying reactions during finishing processes, requiring precise control and specialized knowledge to achieve the desired outcomes.

Rare metals, such as titanium and zirconium, have high melting points and react differently to heat and chemical treatments compared to more common metals. Additionally, their surface characteristics can be highly sensitive, necessitating careful handling to avoid damage or degradation.

Specialized Metal Finishing Machines

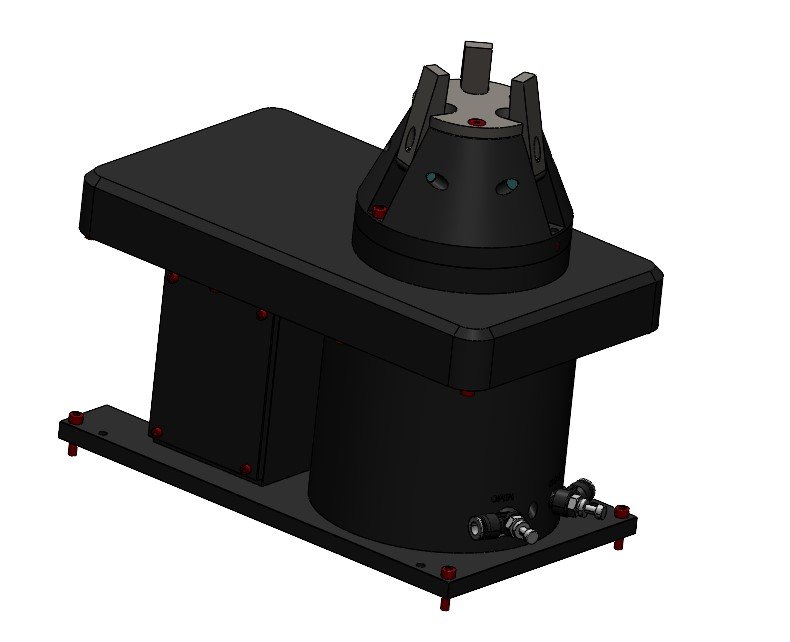

At James Engineering, we specialize in finishing a variety of mixed and rare metal parts using advanced multi-axis Surface Finishing machinery. Our equipment employs abrasive wheels, rotating brushes, and oscillating discs, enabling us to grind, deburr, round, and polish metal components in a single pass.

Manufacturing metal parts demands not only a deep understanding of materials and machinery but also a precise grasp of their intended applications. At James Engineering, we utilize state-of-the-art finishing machines to optimize the properties of mixed and rare metal parts for a wide range of industries. Our advanced deburr techniques ensure minimal material waste and deliver peak performance, making us a trusted partner for leading manufacturers worldwide.

Contact us today to learn more about our specialized metal part processing services and discover how we can enhance your manufacturing processes.

What is Gear Hobbing?

Understanding Gear Hobbing and Deburring in Manufacturing. What is Gear Hobbing? Gear hobbing is a machining process used to cut gears, splines, and sprockets. What is the Difference Between Gear Cutting and Hobbing? Why is it Important to Remove Burrs? What is the Effect of Deburring?

We answer ALL your questions!

Understanding Gear Hobbing and Deburring in Manufacturing

In manufacturing, precision and efficiency reign supreme. At the heart of achieving these goals are understanding two pivotal processes: gear hobbing and deburring. This article will explore what gear hobbing is, distinguish it from gear cutting, and delve into the importance of removing burrs and the effects of deburring.

What is Gear Hobbing?

Gear hobbing is a machining process used to cut gears, splines, and sprockets. It involves using a specialized cutting tool known as a hob, which rotates continuously while being fed into the workpiece to progressively carve out the gear teeth. This process is highly efficient and can produce a wide range of gear sizes and shapes with high precision. Gear hobbing is commonly used in the automotive, aerospace, and machinery industries due to its ability to produce high-quality gears at a relatively low cost.

What is the Difference Between Gear Cutting and Hobbing?

While gear hobbing is a type of gear cutting, not all gear cutting processes are hobbing. Gear cutting is a broad term that encompasses various methods used to create gear teeth, including hobbing, shaping, milling, and broaching.

Gear Hobbing: Utilizes a hob and is suitable for producing both spur and helical gears. It is known for its efficiency and versatility in creating various gear profiles.

Gear Shaping: Uses a reciprocating cutter to cut the gear teeth. It is particularly useful for internal gears and gears with complex shapes.

Gear Milling: Involves using a milling machine and a form cutter to create the gear teeth. This method is typically used for small production runs or prototype gears.

Gear Broaching: Uses a toothed tool called a broach to cut the entire gear profile in a single pass. It is ideal for producing large quantities of gears quickly.

Each of these methods has its advantages and specific applications, but gear hobbing is often favored for its combination of speed, precision, and versatility.

Why is it Important to Remove Burrs?

Burrs are unwanted, rough edges or protrusions that remain on metal parts after machining processes such as cutting, drilling, or grinding. These burrs can have several detrimental effects if not removed:

Safety Hazards: Burrs can cause injuries to workers handling the parts.

Assembly Issues: Burrs can interfere with the proper fitting and functioning of parts in assemblies.

Performance Problems: Burrs can affect the performance and longevity of mechanical components, leading to increased wear and tear or even failure.

Aesthetic Concerns: Burrs can negatively impact the appearance of the final product.

Why is Deburring Necessary?

Deburring is the process of removing burrs from metal parts. It is a crucial step in the manufacturing process for several reasons:

Enhances Safety: By removing sharp edges, deburring prevents potential injuries to workers and end-users.

Improves Functionality: Deburred parts fit together more precisely, ensuring proper assembly and optimal performance of mechanical systems.

Extends Product Life: Deburring reduces friction and wear, which can extend the lifespan of components.

Ensures Quality: Removing burrs improves the overall quality and appearance of the product, making it more attractive to customers and less likely to be returned due to defects.

What is the Effect of Deburring?

The effects of deburring extend beyond mere aesthetics and safety. Deburring can significantly impact the overall quality and performance of manufactured parts. Here are some key effects:

Enhanced Durability: By eliminating stress concentrations that can lead to cracks or failures, deburring contributes to the structural integrity of components.

Improved Precision: Deburred parts have cleaner edges and more accurate dimensions, which is critical for applications requiring high precision.

Better Surface Finish: The removal of burrs results in a smoother surface finish, which can improve the part's functionality and reduce the risk of corrosion.

Increased Efficiency: Parts that fit together properly reduce the likelihood of mechanical failures and downtime, leading to more efficient operation of machinery and equipment.

In conclusion, gear hobbing and deburring are essential processes in the manufacturing industry. Gear hobbing allows for the efficient and precise production of gears, while deburring ensures the safety, functionality, and quality of the final products. Understanding these processes and their significance helps manufacturers produce high-quality components that meet the rigorous demands of various industries.

Unlocking the Power of Hydraulics, Pumps, and Valves

At the core of modern engineering pulses the vital trio of hydraulics, pumps, and valves. These transformative technologies aren’t just tools; they’re the driving force behind industries, enabling precision, power transfer, and unparalleled efficiency across diverse applications.

Understanding Hydraulics: The Power of Fluid Dynamics

At the core of modern engineering pulses the vital trio of hydraulics, pumps, and valves. These transformative technologies aren’t just tools; they’re the driving force behind industries, enabling precision, power transfer, and unparalleled efficiency across diverse applications. Join us as we delve deep into the captivating realm of hydraulics, pumps, and valves, unraveling their significance, real-world applications, and the pioneering manufacturers shaping these dynamic sectors.

Importance in Various Industries

Construction and Infrastructure: Imagine towering cranes effortlessly lifting heavy loads or excavators deftly maneuvering on construction sites. Companies like Caterpillar Inc. and Komatsu Ltd. are renowned for their hydraulic systems powering construction equipment worldwide.

Agriculture: From precision farming to heavy-duty harvesting, hydraulics revolutionize agricultural practices. John Deere's hydraulic solutions in tractors and farm machinery epitomize efficiency and reliability in the field.

Aviation and Aerospace: In the skies, hydraulic systems are the lifeline of aircraft operations. Boeing and Airbus incorporate advanced hydraulic pumps, valves, and actuators from suppliers like Parker Hannifin and Eaton Corporation to ensure safe and precise flight controls.

Automotive Innovation: Your car’s power steering, brakes, and suspension owe their responsiveness to hydraulic systems. Leading automotive suppliers such as Bosch Rexroth and Denso Corporation craft hydraulic components that enhance vehicle performance and safety.

Manufacturing Excellence: Hydraulic presses, robots, and CNC machines drive modern manufacturing. Bosch Rexroth's hydraulic expertise powers industrial machinery, optimizing production processes with unmatched precision.

Key Manufacturers Influencing Industries

Bosch Rexroth AG stands tall as a global leader in hydraulic solutions, catering to automotive, industrial, and mobile applications with unparalleled expertise.

Parker Hannifin Corporation commands respect for its aerospace and industrial hydraulic systems, alongside valves and controls, setting industry standards with each innovation.

Eaton Corporation's influence extends across diverse sectors, from aerospace and automotive to machinery, offering cutting-edge hydraulic components and systems that redefine performance benchmarks.

Caterpillar Inc. dominates the construction and mining equipment landscape, harnessing advanced hydraulics to tackle heavy-duty operations with unmatched precision and reliability.

Nidec Corporation emerges as a pivotal player, revolutionizing hydraulic solutions in various industries with innovative technology and unwavering commitment to excellence.

Wärtsilä Corporation secures its position as a trusted supplier of hydraulic solutions for marine and offshore industries, ensuring reliability and performance even in the most challenging environments.

Education and Innovation

Understanding hydraulics, pumps, and valves is not just essential for engineers and technicians; it’s crucial for anyone curious about modern technology. From elementary principles like Pascal’s Law to advanced electro-hydraulic systems, learning about hydraulics opens doors to innovation and problem-solving across industries.

Powering the World Forward

Hydraulics, pumps, and valves form the backbone of modern engineering, propelling industries toward efficiency, safety, and sustainability. As we embrace technological advancements, education and awareness about these critical components pave the way for groundbreaking innovations and a brighter, more interconnected future. Whether you’re fascinated by machinery or intrigued by aerospace marvels, delving into the world of hydraulics unveils a realm of endless possibilities and engineering marvels shaping our world.

Defense Manufacturing: Fortifying the Front Line of Defense

What is National Defense Transportation Day? It is more than just a date on the calendar; it symbolizes the backbone of our nation’s security infrastructure. What is Armed Forces Day? Click to learn more about

Manufacturing for the Defense Industry: The Engine of Innovation and Security

As we commemorate the days of National Defense Transportation Day on May 17, and Armed Forces Day on May 18, it’s a time to reflect on the critical roles these industries play in safeguarding our nation and to recognize the unsung heroes who make it possible. This article delves into the intricacies of defense transportation, the valor of our armed forces, the vital role of manufacturing in defense, and the innovative contributions of companies like James Engineering in supporting these efforts.

National Defense Transportation: The Lifeline of Security

What is National Defense Transportation Day? It is more than just a date on the calendar; it symbolizes the backbone of our nation’s security infrastructure. From moving troops swiftly to disaster relief operations, defense transportation ensures readiness and response on a global scale. Keywords like logistics, supply chain management, and strategic mobility are not just buzzwords but lifelines in times of crisis and conflict.

Armed Forces Day: Honoring Sacrifice and Service

What is Armed Forces Day? On this day we pay homage to the men and women who serve with unwavering dedication and bravery. Their commitment ensures our freedoms and protects our way of life. From land, sea, and air operations to cybersecurity and space defense, the armed forces embody versatility and strength in the face of evolving threats.

Manufacturing for the Defense Industry: The Engine of Innovation and Security

Behind every military advancement lies the prowess of manufacturing. The defense industry relies on cutting-edge technologies, precision engineering, and stringent quality control measures. Yet, manufacturers in this sector face unique challenges, from regulatory compliance to cybersecurity vulnerabilities. Balancing innovation with security demands a constant vigilance and adaptability.

James Engineering: Empowering Defense Manufacturing Excellence

Click Here to learn about specialized CNC Machines that are playing a pivotal role in military defense manufacturing

Amidst these challenges, companies like James Engineering play a pivotal role. Their expertise in providing advanced finishing solutions elevates manufacturing standards, ensuring the durability, reliability, and performance of critical defense equipment. By partnering with leading manufacturers, James Engineering contributes to the seamless integration of technologies that empower our armed forces worldwide.

A Unified Vision for Security and Progress

As we celebrate National Defense Transportation Day and Armed Forces Day, let us remember that security is not just about strength but also about innovation, collaboration, and resilience. By honoring the past, embracing the present, and innovating for the future, we uphold the ideals of security and progress that define our nation and inspire generations to come.

WHAT IS DEBURRING?

What is Deburring? What is the Deburring Process? Exploring Deburr Techniques, Deburring Challenges, and Deburring Solutions!

What is the deburring process?

Exploring Deburr Techniques, Deburring Challenges, and Solutions!

Imagine crafting external gears that mesh seamlessly, internal gears that turn smoothly, or gearboxes that power machines with precision. The secret sauce to this seamless operation? It's all about deburring, a crucial but often underestimated process.

When you dive into manufacturing parts like external gears, internal gears, pinions, pinion shafts, or gearboxes, you're essentially crafting the building blocks of functionality. Every imperfection, no matter how small, can impact the overall performance. That's where deburring steps in, ensuring that these components meet the highest standards of quality and reliability.

Detail of a metal burr. Metal burrs must be removed to ensure safety, functionality, quality control, and optimal performance of metal gears or components in engineering applications.

Understanding Deburring

What is deburring? Deburring is the method of removing unwanted burrs—tiny, often sharp, imperfections—from machined parts. These burrs can result from various manufacturing processes like CNC machining, plasma cutting, or casting. If left untreated, burrs can compromise part functionality, aesthetics, and safety.

Types of Deburring Techniques

Exploring Deburring Techniques and Challenges

Manual Deburring: This traditional method requires skilled operators using tools like scrapers, files, and brushes to remove burrs. While it allows for precision, it is labor-intensive and can be time-consuming, limiting its scalability for large production volumes.

Machine Deburring: Automated deburring machines offer consistent and efficient burr removal, making them indispensable in modern manufacturing. However, challenges such as complex part geometries and varied burr sizes require advanced technologies for optimal results.

Chemical Deburring: While effective for selective burr removal, chemical deburring demands careful handling of chemicals and disposal, requiring strict adherence to safety and environmental regulations.

Abrasive Deburring: Utilizing abrasive materials for mechanical burr removal can generate heat and friction, leading to potential surface damage or tool wear over time.

Electrochemical Deburring (ECM): Although precise, ECM setups can be costly to implement and maintain, requiring skilled technicians for operation and maintenance.

Thermal Deburring: While effective, thermal deburring methods like flame deburring may introduce heat-related distortions in parts, necessitating additional quality control measures.

Cryogenic Deburring: While innovative, cryogenic deburring requires specialized equipment and expertise in handling cryogenic fluids, adding complexity and cost to the process.

Ultrasonic Deburring: While capable of reaching intricate areas, ultrasonic deburring may struggle with harder materials or thicker burrs, requiring adjustments or supplementary processes.

Brush Deburring: While versatile, brush deburring methods may require frequent tool changes or maintenance, impacting production uptime and efficiency.

Waterjet Deburring: While precise and non-destructive, waterjet deburring may struggle with certain materials or intricate geometries, requiring careful process optimization.

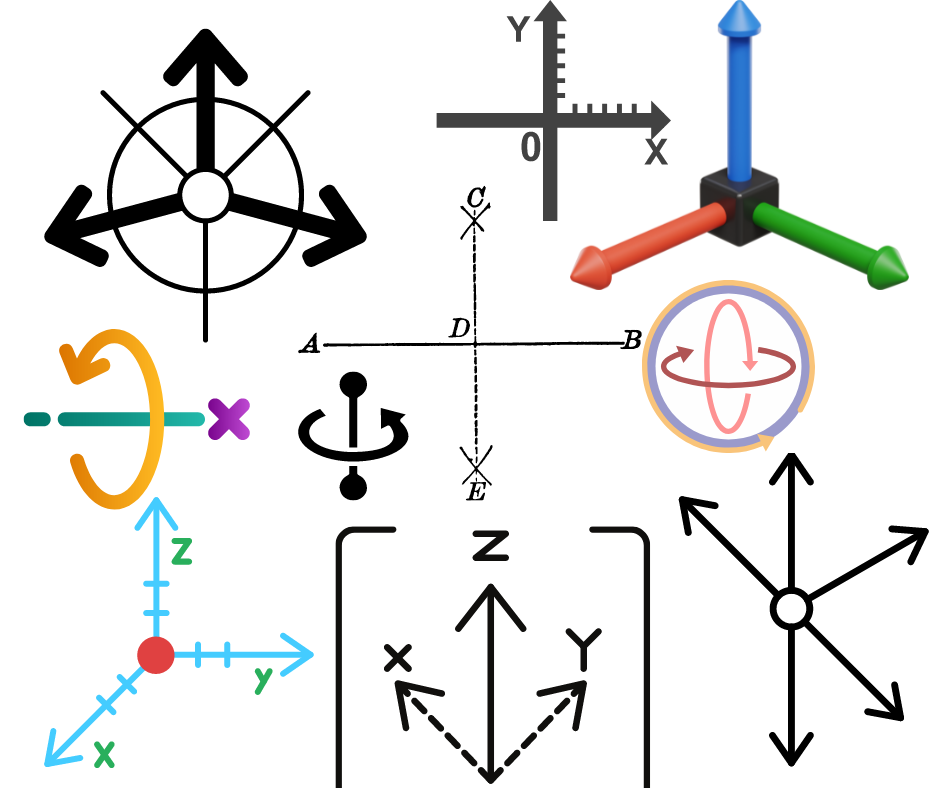

The best machine deburring solution combines multi-axis capability with compliant technology. Unlike rigid robotic systems, multi-axis machines with compliant features offer greater flexibility to adapt to varying part geometries and burr locations. They can adjust tool angles and pressures dynamically, ensuring consistent and precise deburring across different parts. Additionally, machines with various tool options provide versatility, allowing for the use of different deburring methods depending on the part's specific requirements. This flexibility translates to improved productivity, reduced setup times, and enhanced overall quality in the deburring process.

Challenges in Deburring

Despite its importance, deburring poses several challenges:

Complex Part Geometries: Components like external gears, internal gears, and gearboxes often feature intricate geometries, making manual deburring impractical and time-consuming.

Burr Consistency: Burrs can vary in size, shape, and location, requiring tailored deburring solutions for optimal results.

Time and Cost: Manual deburring is labor-intensive and prone to inconsistencies, leading to increased production time and costs.

Automated Deburring Solutions

Automated deburring machines equipped with multi-axis compliant technology, like The MAX, offer unparalleled advantages over traditional deburring methods.

Here's a closer look at why they stand out:

Precision: Multi-axis compliant technology integrates CNC deburring tools into automated machines, ensuring precise burr removal even in complex part geometries like pinions and pinion shafts. This precision enhances part quality and functionality, meeting industry standards effectively.

Consistency: These machines deliver consistent results across batches, reducing rework and ensuring consistent part quality. This reliability is crucial for maintaining product integrity and customer satisfaction.

Efficiency: By automating the deburring process, manufacturers save time, reduce labor costs, and boost overall production efficiency. This efficiency improvement is key for meeting production targets and staying competitive in the market.

Flexibility: Multi-axis compliant technology allows for versatile tool movements, adapting to different part shapes and sizes seamlessly. This flexibility optimizes workflow and resource utilization, enhancing productivity and reducing downtime.

Quality Assurance: With precise control and monitoring capabilities, multi-axis compliant machines ensure stringent quality standards are consistently met. This quality assurance is vital for industries demanding precision and reliability, such as automotive, aerospace, and medical device manufacturing.

The integration of multi-axis compliant technology elevates deburring processes to new levels, offering unmatched precision, consistency, efficiency, flexibility, and quality assurance in modern manufacturing environments. These advantages make them indispensable tools for achieving superior results in part finishing and production optimization.

Choosing the Right Deburring Equipment

When selecting deburring equipment, consider factors such as part complexity, production volume, and budget. Consult reputable deburring machine manufacturers like James Engineering, the deburr master known for their innovative deburring solutions tailored to various industries' needs. Top manufacturing companies go to the deburring experts for the best deburring machines.

Need a Chamfering Machine? Click Here

Burr Removal Methods

Exploring Deburring Tools and Techniques

When it comes to precision manufacturing, the right deburring tools and techniques are essential for achieving flawless finishes and optimal part functionality. Let's delve into the various deburring tools and their unique capabilities:

Deburring Brushes: Specialized brushes designed for deburring tasks effectively remove burrs from machined parts, ensuring smooth and precise edges crucial for product quality and performance.

Abrasive Wheels: Utilizing abrasive materials, such as grinding wheels or belts, abrasive deburring tools remove burrs and imperfections from metal surfaces, providing a consistent and uniform finish.

Chamfering Tools: Chamfering tools bevel edges, improving part aesthetics and reducing sharp edges, enhancing safety during handling and assembly processes.

Radius Forming Attachments: These attachments create precise radii on parts, essential for components like gearboxes and mechanical parts where rounded edges are critical for functionality and longevity.

Polishing Equipment: Polishing tools and materials, such as polishing brushes or compounds, achieve high-quality surface finishes, enhancing part appearance and meeting stringent industry standards.

Filing Tools: Filing tools are used to remove excess material and refine surfaces, maintaining precise dimensions and ensuring smooth edges for seamless part integration.

Washing Systems: Integrated washing systems clean parts thoroughly, removing debris, contaminants, and residual materials post-deburring, ensuring optimal cleanliness for subsequent processes or assembly.

In conclusion, understanding the deburring process, utilizing advanced deburring machines and tools, and choosing the right deburring method for your application are crucial steps in ensuring high-quality, precise machined parts.

By prioritizing deburring before chamfering, polishing, or other finishing processes, manufacturers can uphold the standards necessary for top-notch products in industries relying on precision components like automotive, aerospace, and machinery manufacturing.

If you are looking for the best deburring machines that have stood the test of time for their durability and used by top manufacturing companies across the world for chamfering and all purpose gear and part finishing.

Contact James Engineering at Sales@James-Engineering.com

Mastering Work-holding: The Advantages of Self-Centering Clamps

In engineering and manufacturing, achieving precision and efficiency is not just desirable; it's crucial for success. As industries evolve, so do the tools and technologies used to streamline processes and save valuable time. One such innovation that has transformed the landscape of workholding solutions is the self-centering clamp. Let's explore their benefits and understand the uses.

In engineering and manufacturing, achieving precision and efficiency is not just desirable; it's crucial for success. As industries evolve, so do the tools and technologies used to streamline processes and save valuable time. One such innovation that has transformed the landscape of workholding solutions is the self-centering clamp. Let's explore their benefits and understand the uses.

Understanding Centering Clamps

Centering clamps, also known as engineering clamps, are indispensable tools in various industries where holding workpieces securely and precisely is essential. Traditionally, clamping mechanisms required meticulous adjustments to ensure proper alignment, often leading to time-consuming setups and adjustments. This is where self-centering clamps step in to revolutionize the game.

Unyielding strength in every grip. The JE heavy-duty Work Station is built to handle 1000+ pounds with ease.

Enter Self-Centering Clamps

Self-centering clamps stand out as a beacon of innovation in the realm of workholding solutions. These ingenious devices are designed to automatically center and secure workpieces with lightning-fast precision, eliminating the need for manual adjustments. This "quik-change" feature ensures lightning-fast change-outs, significantly reducing setup time and increasing productivity.

Time-Saving Benefits

Time is money, especially in the competitive landscape of manufacturing. With traditional clamping methods, precious minutes are spent on meticulous adjustments to achieve the desired alignment. Self-centering clamps, on the other hand, drastically reduce setup time by automatically centering the workpiece with unparalleled speed and accuracy. This means engineers and machinists can devote more time to actual production tasks, maximizing efficiency and output.

Labor Advantages

Labor optimization is another crucial aspect of any manufacturing operation. By incorporating self-centering clamps into the workflow, companies can streamline their processes and make more efficient use of human resources. With reduced setup times and simplified operation, skilled workers can focus on tasks that require their expertise, rather than repetitive manual adjustments.

Versatility and Reliability

Self-centering clamps are renowned for their versatility and reliability. See multiple versions here.

Whether in CNC machining, welding, assembly, or any other application requiring precise workholding, these clamps deliver consistent performance, ensuring repeatable results with minimal effort.

Conclusion

In conclusion, self-centering clamps represent a significant leap forward in workholding technology. Their ability to provide lightning-fast change-outs, coupled with the time-saving benefits and labor advantages they offer, make them indispensable tools in modern manufacturing environments. By embracing innovation and efficiency, companies can stay ahead of the curve and unlock new levels of productivity in their operations.

The Advantage of 11-Axis Machining over 5-Axis Machining in High Precision Part Finishing

In the realm of manufacturing, precision is paramount. Achieving high precision in part finishing not only enhances the quality of the final product but also significantly impacts efficiency and cost-effectiveness. Traditional machining methods have paved the way for advanced technologies like 5-axis machining, and now, the evolution continues with the advent of 11-axis machining. In this article, we delve into the nuances of high precision part finishing and explore the distinct advantages offered by 11-axis machining over its 5-axis counterpart.

In the realm of manufacturing, precision is paramount. Achieving high precision in part finishing not only enhances the quality of the final product but also significantly impacts efficiency and cost-effectiveness. Traditional machining methods have paved the way for advanced technologies like 5-axis machining, and now, the evolution continues with the advent of 11-axis machining. In this article, we delve into the nuances of high precision part finishing and explore the distinct advantages offered by 11-axis machining over its 5-axis counterpart.

Understanding High Precision Part Finishing

High precision part finishing involves the intricate process of refining components to exact specifications, ensuring dimensional accuracy, surface finish quality, and overall performance. This meticulous craftsmanship is vital across diverse industries, including aerospace, automotive, medical devices, and beyond, where precision is non-negotiable.

5-Axis Machining: A Step Forward

5-axis machining revolutionized manufacturing by enabling simultaneous movement of the cutting tool along five axes, allowing for enhanced complexity and flexibility in part production. This technology excels in sculpting intricate geometries and contours with remarkable accuracy, reducing setup time and increasing efficiency compared to traditional 3-axis machining.

The Emergence of 11-Axis Machining and Beyond

Building upon the capabilities of 5-axis machining, Multi-axes machining represents the next frontier in precision manufacturing. By incorporating additional rotational and tilting axes, this advanced technology introduces unprecedented levels of versatility and precision to part finishing processes.

Experience precision in action with James Engineering’s state-of-the-art 11-axis 2 Tower , The MAX, all purpose finishing machine – revolutionizing part finishing for top-tier quality and efficiency.

Benefits of 11-Axis Machining over 5-Axis

Enhanced Complex Geometry Machining: With six additional axes at its disposal, 11-axis machining offers unparalleled freedom in maneuvering the cutting tool around complex part geometries. This capability is particularly advantageous for producing intricate components with challenging features, such as undercuts, draft angles, and compound curves.

Optimized Surface Finish: The increased flexibility of 11-axis machining enables precise control over tool paths and cutting angles, resulting in superior surface finish quality. Fine details and delicate features can be meticulously refined, eliminating the need for secondary finishing operations and reducing overall production time.

Improved Tool Accessibility: Complex part geometries often present challenges in tool accessibility during machining. 11-axis machines address this issue by enabling dynamic tool positioning from multiple angles, ensuring optimal reach and coverage across the entire workpiece. This capability minimizes the need for repositioning and mitigates the risk of tool interference, enhancing overall process efficiency.

Streamlined Setup and Fixturing: By reducing the reliance on elaborate fixturing and setup arrangements, 11-axis machining simplifies the preparation process for part finishing. The increased range of motion allows for more flexible workholding solutions, optimizing workflow and reducing setup time and associated costs.

Enhanced Productivity and Cost Efficiency: The precision and efficiency afforded by 11-axis machining translate into tangible benefits for manufacturers. By minimizing material waste, improving cycle times, and reducing the need for secondary operations, this technology streamlines production workflows and enhances overall productivity while maintaining competitive pricing.

The Future of Machining

In the pursuit of precision manufacturing, the transition from 5-axis to Multi Axis machining represents a significant leap forward. By unlocking new levels of versatility, accuracy, and efficiency in part finishing processes, Multi-Axis machining empowers manufacturers to push the boundaries of innovation and meet the exacting demands of modern industries. As this technology continues to evolve, its transformative impact on precision manufacturing will undoubtedly shape the future of the industry, driving advancements in product quality, performance, and competitiveness.

Contact James Engineering on how multi-axis machining can improve your cnc manufacturing process. Sales@James-Engineering.com