WHAT IS DEBURRING?

What is Deburring? What is the Deburring Process? Exploring Deburr Techniques, Deburring Challenges, and Deburring Solutions!

What is the deburring process?

Exploring Deburr Techniques, Deburring Challenges, and Solutions!

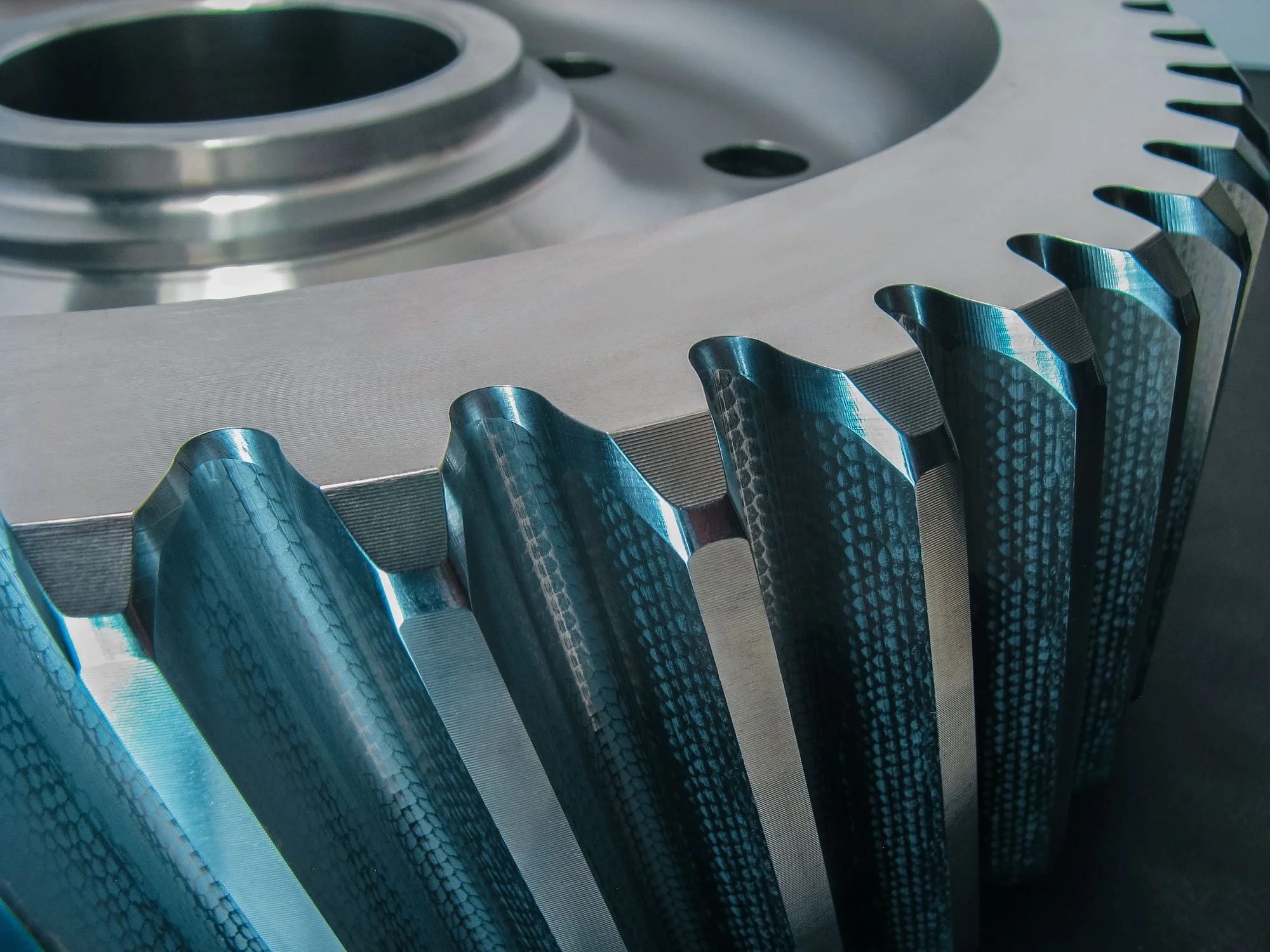

Imagine crafting external gears that mesh seamlessly, internal gears that turn smoothly, or gearboxes that power machines with precision. The secret sauce to this seamless operation? It's all about deburring, a crucial but often underestimated process.

When you dive into manufacturing parts like external gears, internal gears, pinions, pinion shafts, or gearboxes, you're essentially crafting the building blocks of functionality. Every imperfection, no matter how small, can impact the overall performance. That's where deburring steps in, ensuring that these components meet the highest standards of quality and reliability.

Detail of a metal burr. Metal burrs must be removed to ensure safety, functionality, quality control, and optimal performance of metal gears or components in engineering applications.

Understanding Deburring

What is deburring? Deburring is the method of removing unwanted burrs—tiny, often sharp, imperfections—from machined parts. These burrs can result from various manufacturing processes like CNC machining, plasma cutting, or casting. If left untreated, burrs can compromise part functionality, aesthetics, and safety.

Types of Deburring Techniques

Exploring Deburring Techniques and Challenges

Manual Deburring: This traditional method requires skilled operators using tools like scrapers, files, and brushes to remove burrs. While it allows for precision, it is labor-intensive and can be time-consuming, limiting its scalability for large production volumes.

Machine Deburring: Automated deburring machines offer consistent and efficient burr removal, making them indispensable in modern manufacturing. However, challenges such as complex part geometries and varied burr sizes require advanced technologies for optimal results.

Chemical Deburring: While effective for selective burr removal, chemical deburring demands careful handling of chemicals and disposal, requiring strict adherence to safety and environmental regulations.

Abrasive Deburring: Utilizing abrasive materials for mechanical burr removal can generate heat and friction, leading to potential surface damage or tool wear over time.

Electrochemical Deburring (ECM): Although precise, ECM setups can be costly to implement and maintain, requiring skilled technicians for operation and maintenance.

Thermal Deburring: While effective, thermal deburring methods like flame deburring may introduce heat-related distortions in parts, necessitating additional quality control measures.

Cryogenic Deburring: While innovative, cryogenic deburring requires specialized equipment and expertise in handling cryogenic fluids, adding complexity and cost to the process.

Ultrasonic Deburring: While capable of reaching intricate areas, ultrasonic deburring may struggle with harder materials or thicker burrs, requiring adjustments or supplementary processes.

Brush Deburring: While versatile, brush deburring methods may require frequent tool changes or maintenance, impacting production uptime and efficiency.

Waterjet Deburring: While precise and non-destructive, waterjet deburring may struggle with certain materials or intricate geometries, requiring careful process optimization.

The best machine deburring solution combines multi-axis capability with compliant technology. Unlike rigid robotic systems, multi-axis machines with compliant features offer greater flexibility to adapt to varying part geometries and burr locations. They can adjust tool angles and pressures dynamically, ensuring consistent and precise deburring across different parts. Additionally, machines with various tool options provide versatility, allowing for the use of different deburring methods depending on the part's specific requirements. This flexibility translates to improved productivity, reduced setup times, and enhanced overall quality in the deburring process.

Challenges in Deburring

Despite its importance, deburring poses several challenges:

Complex Part Geometries: Components like external gears, internal gears, and gearboxes often feature intricate geometries, making manual deburring impractical and time-consuming.

Burr Consistency: Burrs can vary in size, shape, and location, requiring tailored deburring solutions for optimal results.

Time and Cost: Manual deburring is labor-intensive and prone to inconsistencies, leading to increased production time and costs.

Automated Deburring Solutions

Automated deburring machines equipped with multi-axis compliant technology, like The MAX, offer unparalleled advantages over traditional deburring methods.

Here's a closer look at why they stand out:

Precision: Multi-axis compliant technology integrates CNC deburring tools into automated machines, ensuring precise burr removal even in complex part geometries like pinions and pinion shafts. This precision enhances part quality and functionality, meeting industry standards effectively.

Consistency: These machines deliver consistent results across batches, reducing rework and ensuring consistent part quality. This reliability is crucial for maintaining product integrity and customer satisfaction.

Efficiency: By automating the deburring process, manufacturers save time, reduce labor costs, and boost overall production efficiency. This efficiency improvement is key for meeting production targets and staying competitive in the market.

Flexibility: Multi-axis compliant technology allows for versatile tool movements, adapting to different part shapes and sizes seamlessly. This flexibility optimizes workflow and resource utilization, enhancing productivity and reducing downtime.

Quality Assurance: With precise control and monitoring capabilities, multi-axis compliant machines ensure stringent quality standards are consistently met. This quality assurance is vital for industries demanding precision and reliability, such as automotive, aerospace, and medical device manufacturing.

The integration of multi-axis compliant technology elevates deburring processes to new levels, offering unmatched precision, consistency, efficiency, flexibility, and quality assurance in modern manufacturing environments. These advantages make them indispensable tools for achieving superior results in part finishing and production optimization.

Choosing the Right Deburring Equipment

When selecting deburring equipment, consider factors such as part complexity, production volume, and budget. Consult reputable deburring machine manufacturers like James Engineering, the deburr master known for their innovative deburring solutions tailored to various industries' needs. Top manufacturing companies go to the deburring experts for the best deburring machines.

Need a Chamfering Machine? Click Here

Burr Removal Methods

Exploring Deburring Tools and Techniques

When it comes to precision manufacturing, the right deburring tools and techniques are essential for achieving flawless finishes and optimal part functionality. Let's delve into the various deburring tools and their unique capabilities:

Deburring Brushes: Specialized brushes designed for deburring tasks effectively remove burrs from machined parts, ensuring smooth and precise edges crucial for product quality and performance.

Abrasive Wheels: Utilizing abrasive materials, such as grinding wheels or belts, abrasive deburring tools remove burrs and imperfections from metal surfaces, providing a consistent and uniform finish.

Chamfering Tools: Chamfering tools bevel edges, improving part aesthetics and reducing sharp edges, enhancing safety during handling and assembly processes.

Radius Forming Attachments: These attachments create precise radii on parts, essential for components like gearboxes and mechanical parts where rounded edges are critical for functionality and longevity.

Polishing Equipment: Polishing tools and materials, such as polishing brushes or compounds, achieve high-quality surface finishes, enhancing part appearance and meeting stringent industry standards.

Filing Tools: Filing tools are used to remove excess material and refine surfaces, maintaining precise dimensions and ensuring smooth edges for seamless part integration.

Washing Systems: Integrated washing systems clean parts thoroughly, removing debris, contaminants, and residual materials post-deburring, ensuring optimal cleanliness for subsequent processes or assembly.

In conclusion, understanding the deburring process, utilizing advanced deburring machines and tools, and choosing the right deburring method for your application are crucial steps in ensuring high-quality, precise machined parts.

By prioritizing deburring before chamfering, polishing, or other finishing processes, manufacturers can uphold the standards necessary for top-notch products in industries relying on precision components like automotive, aerospace, and machinery manufacturing.

If you are looking for the best deburring machines that have stood the test of time for their durability and used by top manufacturing companies across the world for chamfering and all purpose gear and part finishing.

Contact James Engineering at Sales@James-Engineering.com

The Power of Compliant Technology, the Magic Behind The MAX

There’s major problem in the industry! Find out how we solve it!

See how James Engineering is solving the problem of non-inform parts , watch the video below

Precision is key.

Yet, the reality often falls short of the ideal, with parts turning out to be anything but perfect. Scott Richards, Vice President of James Engineering, delves into the heart of this challenge, shedding light on the industry's persistent problem and the innovative solution James Engineering has developed.

Solving the Problem of Non-Uniform Parts

Watch below as Scott Richards opens the discussion by addressing a common yet critical issue in manufacturing: non-uniformity. Many parts, despite appearing round, lack uniformity in dimensions. This discrepancy poses a significant challenge, particularly in processes like deburring, where precision is paramount.

Traditional approaches, including vision systems and CNC machines with complex algorithms, have failed to adequately address this issue over the past four decades. However, James Engineering's breakthrough compliant technology offers a revolutionary solution.

The Essence of Compliant Technology

Compliant technology mimics the human hand's ability to sense and adapt to surfaces in real-time. Unlike conventional methods reliant on lasers or mathematical equations, compliant technology mechanically senses and reacts to surface variations as they occur. This approach eliminates the need for predictive algorithms and ensures consistent results, even with perishable tools prone to uneven wear.

Navigating the Challenges of Inconsistent Parts

Watch as Scott delves deeper into the complexities of inconsistent parts, emphasizing the significant impact of stress relief in machining processes. As parts undergo machining, stress relief can cause unexpected distortions, leading to mismatches between the intended model and the final product. This disparity poses challenges for CNC machines and robots programmed to expect uniformity.

Addressing the Inconsistency

James Engineering's compliant technology offers a versatile solution to address inconsistencies across various manufacturing processes. By dynamically adjusting to surface variations, the technology ensures precise results, regardless of a part's shape or dimensions. Unlike traditional methods reliant on human intervention, compliant technology offers unparalleled accuracy and repeatability, enhancing overall manufacturing efficiency.

Empowering Manufacturers with Precision

In a competitive manufacturing landscape, precision is non-negotiable. James Engineering's compliant technology empowers manufacturers to achieve unparalleled precision and consistency, revolutionizing traditional manufacturing processes. By eliminating the reliance on manual intervention and predictive algorithms, the technology streamlines operations, reduces costs, and enhances product quality.

Embracing the Future of Manufacturing

As industries evolve and technology advances, embracing innovative solutions becomes imperative for sustained success. James Engineering's compliant technology represents a paradigm shift in manufacturing, offering a glimpse into the future of precision engineering.

Scott Richards's insights into the transformative potential of compliant technology underscore its significance in revolutionizing manufacturing. By bridging the gap between traditional methods and emerging challenges, James Engineering paves the way for a new era of precision and efficiency in manufacturing.

Incorporating compliant technology into manufacturing processes holds the promise of unlocking new possibilities and driving unprecedented levels of efficiency and precision. As industries continue to evolve, embracing such innovations will be crucial for staying ahead of the curve.

Chamfer Explained - What is the Purpose of a Chamfer?

Chamfering’s importance is paramount in various fields such as civil engineering, woodworking, and machining. But what exactly is chamfering and what is its purpose?

Chamfering in Engineering

Chamfering’s importance is paramount in various fields such as civil engineering, woodworking, and machining. But what exactly is chamfering and what is its purpose?

Chamfer Definition

Chamfering refers to the process of creating a symmetrical edge by removing a right-angled corner or edge. Depending on component size, this may seem like a simple adjustment, but its implications are profound. Especially in industries like aerospace, automotive, etc; where precision is a must.

(Before/After)

Deburred and Chamfered with a James Engineering Max System

What is The Purpose of Gear Chamfering?

If parts and gears are left with no chamfer sharp angles can exist, posing a serious risk to operability and safety. These angles become stress points and the component becomes vulnerable to damage and fatigue. In machining, impacts, vibrations, and extreme heat exacerbate these risks and can lead to breaks or fractures. Damage like this can impact the performance of the entire machine. With a chamfer, the stress of the sharp edge is appropriately distributed and the risk of damage is eliminated.

Reducing Stress with a Chamfer

As an example, consider a 90-degree angle. Chamfering the angle flat and creating two 45-degree angles significantly decreases the stress of that edge. This minor altercation greatly extends the lifespan of components, ensuring durability and reliability.

90° angle cut to two 45° angles to remove stress point.

Optimizing the Gear Chamfering Process

Even though a chamfer is only a slight alter, chamfering can be a very tedious, time-consuming, and inconsistent process. However, advanced technologies have revolutionized this process. With our MAX automatic and manual gear chamfering machines, chamfering is no longer a challenge–it’s a seamless operation.

Our gear chamfering machines are engineered for an operator of any experience without compromising on precision, quality, efficiency, or sustainability. Whether it’s a large-scale project or a small intricate detailed job, our unique machines are tailored to meet any need. We specialize in custom solutions, whether it’s large single-part batches or varying parts in each cycle, we will fully optimize your process.

Conclusion

Chamfering plays a vital role in enhancing the performance and longevity of components across various industries. By understanding chamfering’s purpose and utilizing advanced technologies, engineers can ensure that their products will withstand the test of time. Reach out to learn how MAX and manual machines can optimize your chamfering process and elevate your operation to new heights.

Chamfer Explained 3D Animation

Types of Deburring

Let’s dive in to eight different methods of deburring!

Punch Deburring

Since its perfection in 1770, sheet metal has become a commonly used material within the manufacturing world. One of the most popular ways of cutting and manipulating sheet metal is a method called “punching”. A punch machine uses interchangeable tools to cut out shapes from the sheet metal, and it’s vital that these tools are sharp. If they aren’t, they require more force to cut through the metal, which can lead to the formation of burrs. Punch machines can deburr the pieces of sheet metal they just cut, and they do so with another set of interchangeable tools, which are meant for deburring. This method of deburring works well for pieces cut from sheet metal, but it’s extremely limited when it comes to parts with complex geometries.

Tumbling Deburring

This method involves parts/gears being tumbled in a barrel full of water and loose materials (known as tumbling media), such as glass beads, steel, or plastic. The force of the material and parts tumbling against each other will break off any present burrs and smooth out a part’s surface. Operators must be able to choose their media correctly, as some will do extreme damage to gears/parts made of other certain materials. For instance, steel parts must be paired with steel material. Tumbling is a good option for larger parts/gears, as it is a quicker way to remove their burrs compared to doing it by hand, and they are less likely to suffer overall structural damage from it. However, that risk is still there, and it can ultimately do more harm than good.

Vibratory Deburring

Vibratory deburring is like the tumbling method in the sense that parts are put into a barrel with tumbling media, but it’s more effective and gentler than its cousin method. When the loose material is vibrated against parts/gears, the force shears off burrs and other imperfections with equal force, making it a safe method for smaller, more delicate parts. This process is used frequently within industries such as the aerospace or medical industries and can even be used for parts made of wood or plastic.

Cryogenic Deburring

The cryogenic deburring method is similar to freezing off a wart. Parts are put into low-temperature chambers, where burrs are then frozen until brittle. The burrs will then get knocked off part surfaces when non-abrasive media is thrown into the chamber. This process doesn’t leave residue and preserves the surfaces of parts of any size. It’s a good option for processing large amounts of parts/gears at once, but it still lacks the precision that is necessary for complex parts.

Hand Deburring

This might be the most common—and the most time consuming—deburring method out there. Workers use handheld tools to manually complete processes such as brushing, edging, chamfering, polishing, and of course deburring. While this method allows for focused precision, workers are limited to working on one part at a time, making it extremely inefficient for high or medium volume shops. These workers also require adequate training and experience, seeing as one mistake can scrap an entire part; a little too much material taken off a part/gear can cause it to not fit into its greater assembly properly and affect its long-term efficiency. Another issue with hand deburring is that consistent chamfers are hard to achieve with it, and chamfers of poor quality will also affect the function of a larger assembly. Some manufacturers still prefer hand deburring to other methods, but it costs too much time and money to be used widely.

Electrochemical Deburring

Electrochemical deburring is a unique method of deburring that shoots currents of voltage between a cathode and a burr, ultimately dissolving said burr. This process can remove any sort of excess unwanted surface material. It’s important to maintain a gap between the cathode and part needing deburring, as this gap (paired with an electrolyte solution) allow for the transfer of voltage. It’s much more precise compared to methods such as punch deburring or tumbling deburring, and allows holes, cross holes, and intersections to be deburred easily. However, this method is limited to a small variety of materials seeing as some don’t contain the required levels of conductivity.

Thermal Deburring

The thermal deburring technique is carried out by placing parts in a pressurized chamber and setting off a series of controlled combustions, which essentially melt off any burrs or surface imperfections. The overall structure of the part/gear in the chamber isn’t harmed due to how momentary these mini explosions are, however the risk of excessive heat damage is still present. Once the burrs are removed, the part/gear is left with a thin film coating its surface and it must be cleared off before it is further processed. While efficient when it comes to removing multiple burrs/surface imperfections at once, it also lacks the necessary precision required by some industries, such as the aerospace industry.

Machine Deburring

Machine deburring is the most effective method of deburring when it comes to timeliness, cost efficiency, and precision, and has been gaining popularity as the demand for all three of these factors has grown dramatically over the course of the last few years. Machine deburring extends to both CNC machines and finishing machines, such as the MAX System from James Engineering, a high precision deburring and chamfering machine. CNC machines are most efficient when it comes to cutting parts, but they also have limited deburring capabilities. The MAX System and its one-of-a-kind technologies allows the machine to deburr and chamfer, radius, wash, and brush a part concurrently. This is due to its multi-tooling feature, which is customizable to any company’s needs. It also features an 11-axis overhead gantry system, making any angle reachable. The MAX is a great option for both parts and gears of any size and any complexity, and with Focused Deburring (a technology unique to James Engineering), burrs can be targeted—something only James Engineering finishing systems are capable of.

Which one is right for you?

These eight methods of deburring are used for a wide range of industries, parts, and gears, and each have their own pros and cons. Finding the right one for your company ultimately depends on the volume at which your shop is producing, and what parts/gears you produce. The lower your shop’s volume is, and the simpler your parts, methods such as hand deburring can be a reasonable choice. If your shop is producing at a high volume and working with a wide array of gears/parts of a variety of materials, a specialized finishing machine such as the MAX System is the most time and cost-effective move to make. Doing your own research is important, and you know your shop’s needs the best… but you can never go wrong with the MAX.