Defense Manufacturing: Fortifying the Front Line of Defense

What is National Defense Transportation Day? It is more than just a date on the calendar; it symbolizes the backbone of our nation’s security infrastructure. What is Armed Forces Day? Click to learn more about

Manufacturing for the Defense Industry: The Engine of Innovation and Security

As we commemorate the days of National Defense Transportation Day on May 17, and Armed Forces Day on May 18, it’s a time to reflect on the critical roles these industries play in safeguarding our nation and to recognize the unsung heroes who make it possible. This article delves into the intricacies of defense transportation, the valor of our armed forces, the vital role of manufacturing in defense, and the innovative contributions of companies like James Engineering in supporting these efforts.

National Defense Transportation: The Lifeline of Security

What is National Defense Transportation Day? It is more than just a date on the calendar; it symbolizes the backbone of our nation’s security infrastructure. From moving troops swiftly to disaster relief operations, defense transportation ensures readiness and response on a global scale. Keywords like logistics, supply chain management, and strategic mobility are not just buzzwords but lifelines in times of crisis and conflict.

Armed Forces Day: Honoring Sacrifice and Service

What is Armed Forces Day? On this day we pay homage to the men and women who serve with unwavering dedication and bravery. Their commitment ensures our freedoms and protects our way of life. From land, sea, and air operations to cybersecurity and space defense, the armed forces embody versatility and strength in the face of evolving threats.

Manufacturing for the Defense Industry: The Engine of Innovation and Security

Behind every military advancement lies the prowess of manufacturing. The defense industry relies on cutting-edge technologies, precision engineering, and stringent quality control measures. Yet, manufacturers in this sector face unique challenges, from regulatory compliance to cybersecurity vulnerabilities. Balancing innovation with security demands a constant vigilance and adaptability.

James Engineering: Empowering Defense Manufacturing Excellence

Click Here to learn about specialized CNC Machines that are playing a pivotal role in military defense manufacturing

Amidst these challenges, companies like James Engineering play a pivotal role. Their expertise in providing advanced finishing solutions elevates manufacturing standards, ensuring the durability, reliability, and performance of critical defense equipment. By partnering with leading manufacturers, James Engineering contributes to the seamless integration of technologies that empower our armed forces worldwide.

A Unified Vision for Security and Progress

As we celebrate National Defense Transportation Day and Armed Forces Day, let us remember that security is not just about strength but also about innovation, collaboration, and resilience. By honoring the past, embracing the present, and innovating for the future, we uphold the ideals of security and progress that define our nation and inspire generations to come.

Mastering Deburring: From Micro Parts to Massive Gears

In manufacturing, the size of parts can pose substantial challenges when it comes to deburring and chamfering processes.

In manufacturing, the size of parts can pose substantial challenges when it comes to deburring and chamfering processes. Whether you're a manufacturer dealing with delicate medical micro components, large mining gears, or life critical aerospace and defense parts requiring precision, finding the right deburring machine is critical. At James Engineering, we specialize in deburring solutions tailored to handle the diverse needs of modern manufacturing.

Deburring Machine for Small Parts and Micro Components

Deburring and chamfering small parts and micro components demand precision and finesse. Our surface finishing machines are designed with advanced compliance technology to cater to these exacting requirements. From intricate micro parts to precision components, our machines ensure consistent and high-quality results every time. Fully automated features reduce human intervention, freeing up your workforce for more specialized tasks.

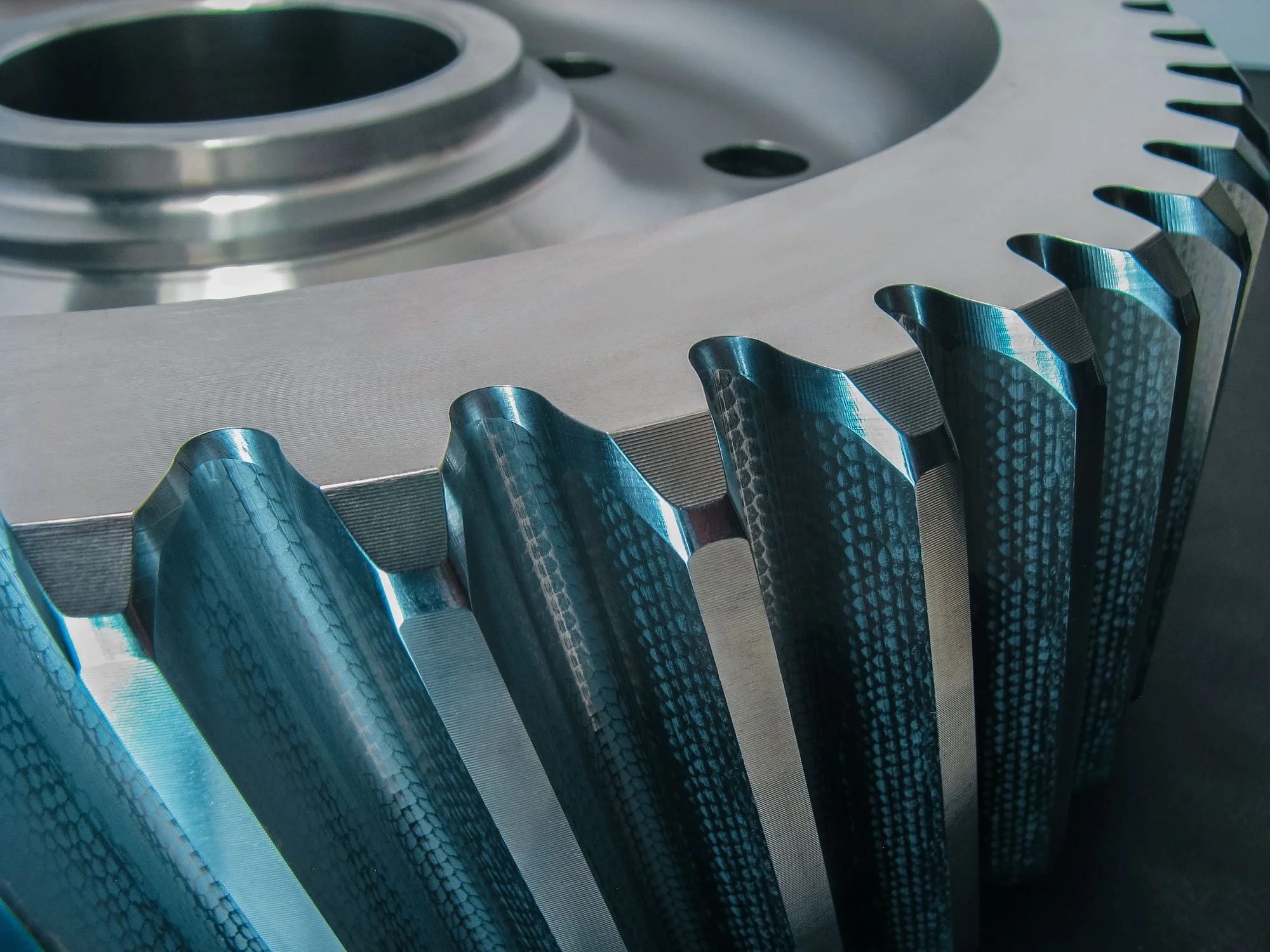

Deburring Machine for Large Gears

Dealing with large gears presents unique challenges in deburring and chamfering. Our specialized large gear deburring machines are equipped to handle these massive components with ease. Automated processes streamline operations, delivering efficient and reliable results while reducing manual labor costs. Consistent deburring of large gears ensures optimal performance and longevity in your machinery.

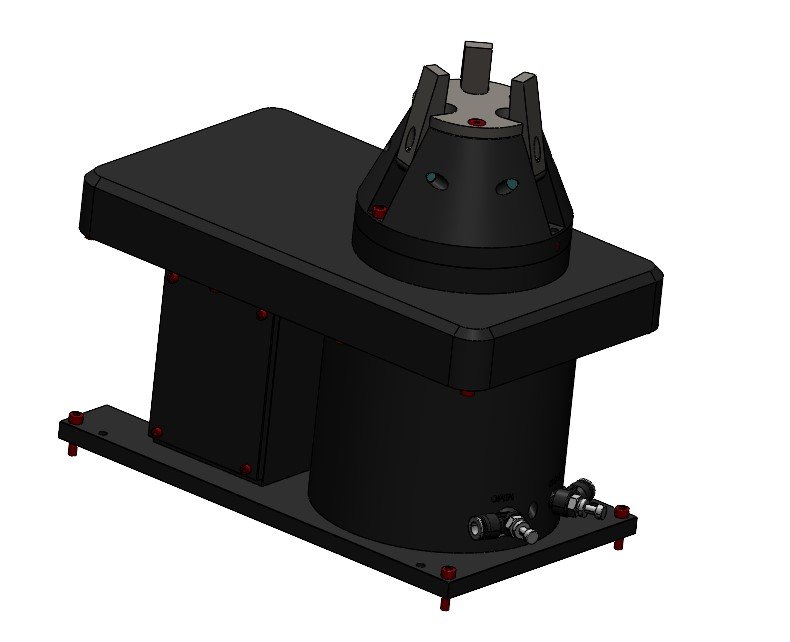

James Engineering redesigned their famous MAX System with an open back to accommodate large gear deburring and chamfering

Deburring Machine for Aerospace and Defense Parts

In the aerospace and defense industries, precision is non-negotiable. Our deburring machines are engineered to meet the stringent demands of these sectors. Whether deburring intricate aerospace components or critical defense parts, our machines deliver unparalleled accuracy and repeatability. Customizable settings allow for precise adjustments to match specific part requirements, ensuring adherence to strict industry standards.

Wide-Range Surface Finishing Machines

Don't let part size limitations hinder your manufacturing excellence. James Engineering offers specialized deburring machines tailored for small parts, micro components, large gears, and aerospace/defense parts. Experience consistent quality, efficiency, and cost-effectiveness in your deburring processes.

Do I need a Chamfer Machine or a Deburring Machine?

Learn the difference here

Contact us today to explore how our advanced surface finishing technology can elevate your manufacturing operations across diverse part sizes and industries.

Master large gear deburring or small gear finishing with James Engineering's complete deburring solutions!

The Power of Compliant Technology, the Magic Behind The MAX

There’s major problem in the industry! Find out how we solve it!

See how James Engineering is solving the problem of non-inform parts , watch the video below

Precision is key.

Yet, the reality often falls short of the ideal, with parts turning out to be anything but perfect. Scott Richards, Vice President of James Engineering, delves into the heart of this challenge, shedding light on the industry's persistent problem and the innovative solution James Engineering has developed.

Solving the Problem of Non-Uniform Parts

Watch below as Scott Richards opens the discussion by addressing a common yet critical issue in manufacturing: non-uniformity. Many parts, despite appearing round, lack uniformity in dimensions. This discrepancy poses a significant challenge, particularly in processes like deburring, where precision is paramount.

Traditional approaches, including vision systems and CNC machines with complex algorithms, have failed to adequately address this issue over the past four decades. However, James Engineering's breakthrough compliant technology offers a revolutionary solution.

The Essence of Compliant Technology

Compliant technology mimics the human hand's ability to sense and adapt to surfaces in real-time. Unlike conventional methods reliant on lasers or mathematical equations, compliant technology mechanically senses and reacts to surface variations as they occur. This approach eliminates the need for predictive algorithms and ensures consistent results, even with perishable tools prone to uneven wear.

Navigating the Challenges of Inconsistent Parts

Watch as Scott delves deeper into the complexities of inconsistent parts, emphasizing the significant impact of stress relief in machining processes. As parts undergo machining, stress relief can cause unexpected distortions, leading to mismatches between the intended model and the final product. This disparity poses challenges for CNC machines and robots programmed to expect uniformity.

Addressing the Inconsistency

James Engineering's compliant technology offers a versatile solution to address inconsistencies across various manufacturing processes. By dynamically adjusting to surface variations, the technology ensures precise results, regardless of a part's shape or dimensions. Unlike traditional methods reliant on human intervention, compliant technology offers unparalleled accuracy and repeatability, enhancing overall manufacturing efficiency.

Empowering Manufacturers with Precision

In a competitive manufacturing landscape, precision is non-negotiable. James Engineering's compliant technology empowers manufacturers to achieve unparalleled precision and consistency, revolutionizing traditional manufacturing processes. By eliminating the reliance on manual intervention and predictive algorithms, the technology streamlines operations, reduces costs, and enhances product quality.

Embracing the Future of Manufacturing

As industries evolve and technology advances, embracing innovative solutions becomes imperative for sustained success. James Engineering's compliant technology represents a paradigm shift in manufacturing, offering a glimpse into the future of precision engineering.

Scott Richards's insights into the transformative potential of compliant technology underscore its significance in revolutionizing manufacturing. By bridging the gap between traditional methods and emerging challenges, James Engineering paves the way for a new era of precision and efficiency in manufacturing.

Incorporating compliant technology into manufacturing processes holds the promise of unlocking new possibilities and driving unprecedented levels of efficiency and precision. As industries continue to evolve, embracing such innovations will be crucial for staying ahead of the curve.

Mastering Work-holding: The Advantages of Self-Centering Clamps

In engineering and manufacturing, achieving precision and efficiency is not just desirable; it's crucial for success. As industries evolve, so do the tools and technologies used to streamline processes and save valuable time. One such innovation that has transformed the landscape of workholding solutions is the self-centering clamp. Let's explore their benefits and understand the uses.

In engineering and manufacturing, achieving precision and efficiency is not just desirable; it's crucial for success. As industries evolve, so do the tools and technologies used to streamline processes and save valuable time. One such innovation that has transformed the landscape of workholding solutions is the self-centering clamp. Let's explore their benefits and understand the uses.

Understanding Centering Clamps

Centering clamps, also known as engineering clamps, are indispensable tools in various industries where holding workpieces securely and precisely is essential. Traditionally, clamping mechanisms required meticulous adjustments to ensure proper alignment, often leading to time-consuming setups and adjustments. This is where self-centering clamps step in to revolutionize the game.

Unyielding strength in every grip. The JE heavy-duty Work Station is built to handle 1000+ pounds with ease.

Enter Self-Centering Clamps

Self-centering clamps stand out as a beacon of innovation in the realm of workholding solutions. These ingenious devices are designed to automatically center and secure workpieces with lightning-fast precision, eliminating the need for manual adjustments. This "quik-change" feature ensures lightning-fast change-outs, significantly reducing setup time and increasing productivity.

Time-Saving Benefits

Time is money, especially in the competitive landscape of manufacturing. With traditional clamping methods, precious minutes are spent on meticulous adjustments to achieve the desired alignment. Self-centering clamps, on the other hand, drastically reduce setup time by automatically centering the workpiece with unparalleled speed and accuracy. This means engineers and machinists can devote more time to actual production tasks, maximizing efficiency and output.

Labor Advantages

Labor optimization is another crucial aspect of any manufacturing operation. By incorporating self-centering clamps into the workflow, companies can streamline their processes and make more efficient use of human resources. With reduced setup times and simplified operation, skilled workers can focus on tasks that require their expertise, rather than repetitive manual adjustments.

Versatility and Reliability

Self-centering clamps are renowned for their versatility and reliability. See multiple versions here.

Whether in CNC machining, welding, assembly, or any other application requiring precise workholding, these clamps deliver consistent performance, ensuring repeatable results with minimal effort.

Conclusion

In conclusion, self-centering clamps represent a significant leap forward in workholding technology. Their ability to provide lightning-fast change-outs, coupled with the time-saving benefits and labor advantages they offer, make them indispensable tools in modern manufacturing environments. By embracing innovation and efficiency, companies can stay ahead of the curve and unlock new levels of productivity in their operations.

Chamfer Explained - What is the Purpose of a Chamfer?

Chamfering’s importance is paramount in various fields such as civil engineering, woodworking, and machining. But what exactly is chamfering and what is its purpose?

Chamfering in Engineering

Chamfering’s importance is paramount in various fields such as civil engineering, woodworking, and machining. But what exactly is chamfering and what is its purpose?

Chamfer Definition

Chamfering refers to the process of creating a symmetrical edge by removing a right-angled corner or edge. Depending on component size, this may seem like a simple adjustment, but its implications are profound. Especially in industries like aerospace, automotive, etc; where precision is a must.

(Before/After)

Deburred and Chamfered with a James Engineering Max System

What is The Purpose of Gear Chamfering?

If parts and gears are left with no chamfer sharp angles can exist, posing a serious risk to operability and safety. These angles become stress points and the component becomes vulnerable to damage and fatigue. In machining, impacts, vibrations, and extreme heat exacerbate these risks and can lead to breaks or fractures. Damage like this can impact the performance of the entire machine. With a chamfer, the stress of the sharp edge is appropriately distributed and the risk of damage is eliminated.

Reducing Stress with a Chamfer

As an example, consider a 90-degree angle. Chamfering the angle flat and creating two 45-degree angles significantly decreases the stress of that edge. This minor altercation greatly extends the lifespan of components, ensuring durability and reliability.

90° angle cut to two 45° angles to remove stress point.

Optimizing the Gear Chamfering Process

Even though a chamfer is only a slight alter, chamfering can be a very tedious, time-consuming, and inconsistent process. However, advanced technologies have revolutionized this process. With our MAX automatic and manual gear chamfering machines, chamfering is no longer a challenge–it’s a seamless operation.

Our gear chamfering machines are engineered for an operator of any experience without compromising on precision, quality, efficiency, or sustainability. Whether it’s a large-scale project or a small intricate detailed job, our unique machines are tailored to meet any need. We specialize in custom solutions, whether it’s large single-part batches or varying parts in each cycle, we will fully optimize your process.

Conclusion

Chamfering plays a vital role in enhancing the performance and longevity of components across various industries. By understanding chamfering’s purpose and utilizing advanced technologies, engineers can ensure that their products will withstand the test of time. Reach out to learn how MAX and manual machines can optimize your chamfering process and elevate your operation to new heights.

Chamfer Explained 3D Animation

Deburring and Part Finishing in the Aerospace Sector: Exceeding Industry Standards

In the dynamic world of aerospace engineering, precision and quality are paramount. Every component, no matter how small, plays a crucial role in the overall performance and safety of an aircraft. One often overlooked but essential process in aerospace manufacturing is deburring and part finishing. This article explores the significance of deburring, its role in meeting industry standards, and the latest techniques employed by top engineers in the aerospace sector.

In the dynamic world of aerospace engineering, precision and quality are paramount. Every component, no matter how small, plays a crucial role in the overall performance and safety of an aircraft. One often overlooked but essential process in aerospace manufacturing is deburring and part finishing. This article explores the significance of deburring, its role in meeting industry standards, and the latest techniques employed by top engineers in the aerospace sector.

Apache Longbow manufactured by Boeing

Understanding Deburring:

Deburring is the process of removing unwanted rough edges, burrs, or imperfections from machined or manufactured parts. In aerospace, where precision is non-negotiable, deburring ensures that components fit seamlessly together, reducing the risk of mechanical failure and enhancing overall efficiency.

Importance in Aerospace Manufacturing:

Aerospace components undergo intricate machining processes, leaving behind sharp edges and burrs. These imperfections can compromise the structural integrity of the parts and, consequently, the entire aircraft. Deburring is not merely a cosmetic enhancement; it is a critical step in maintaining the safety and reliability of aerospace systems.

Industry Standards:

The aerospace industry adheres to rigorous standards and regulations to ensure the highest level of safety and performance. Deburring plays a pivotal role in meeting these standards, as components must not only meet precise dimensional specifications but also undergo thorough inspection to eliminate any defects that could compromise the integrity of the final product.

an aerospace finish does not allow for any

grinding marks

surface blemishing

surface scratches

any jagged edges

inconsistencies and so on.

since most parts are “life critical”,

THE AEROSPACE INDUSTRY demands perfection.

F-22 Raptor Lockheed Martin/Boeing

Latest Techniques in Aerospace Deburring:

As technology advances, so do the techniques employed in aerospace deburring. Top aerospace and defense producers now utilize state-of-the-art equipment, such as The MAX, an 11-axis multi-finishing system that offers unparalleled accuracy, consistency, and speed in finishing processes. The use of the patented Focused Deburring, ensures that even the most intricate components can be deburred with precision, meeting the stringent requirements of aerospace applications. While also contributing to increased efficiency and cost-effectiveness in the overall manufacturing process.

THE MAX

11-Axis Advanced Multi-Finishing System

Equipped with up to 4 different precision finishing tools has revolutionized the aerospace and defense industry.

In the demanding field of aerospace engineering, every detail matters. Deburring and part finishing are essential steps in ensuring the integrity, safety, and performance of aerospace components. As technology continues to evolve, top manufacturers will continue to embrace innovative solutions to meet and exceed industry standards. The combination of precision, automation, and advanced methods propels aerospace manufacturing into a future where safety and quality are never compromised.

To learn more about The MAX click here.

If you’re interested in learning how to improve your own finishing process, give James Engineering a call at (303) 444-6787, or email us at Sales@James-Engineering.com.