The Difference Between Grinding, Polishing, and Deburring

These three machining processes all seem frustratingly similar—so what makes them different from each other?

Grinding, polishing, and deburring—anybody who knows anything about the precision machining process knows that these three processes are a.) crucial, and b.) acts of surface finishing. These three processes are very similar to each other, and for decades have been making people ask the same questions: What’s the difference? And why do we need to do all three processes? Both of these questions are valid, and we have the answers to both below.

The difference between grinding, polishing, and deburring.

1. Grinding

This is the process of removing material and shaping a workpiece into its final form. Grinding can be done on a multitude of materials, such as plastic, ceramic, and many different metals (stainless steel, titanium, high-nickel alloys, etc.). In order to complete this process, grinding wheels of different abrasives are used in various machines made specifically for grinding. It’s important that the correct kind of abrasive is used, as too soft of an abrasive can’t grind a workpiece enough, while too hard of an abrasive will damage a workpiece and result in decreased part quality or scrapped part. Overall, grinding is essential because it improves a part’s surface finish, which not only provides the aesthetic many industries require, but also ensures the removal of pesky surface imperfections.

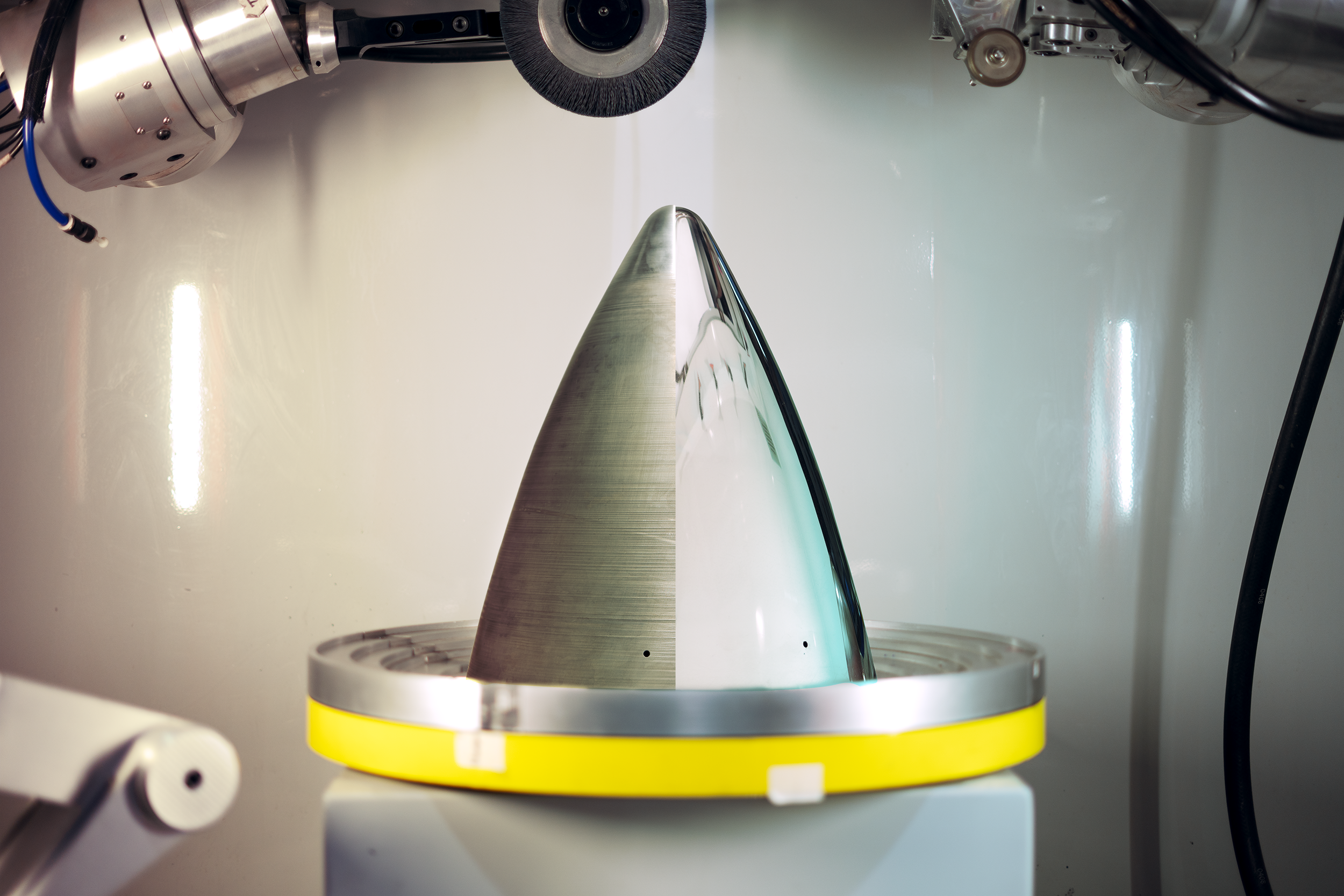

2. Polishing

Polishing is the process surface finishing, which is also known as the process of improving surface quality. Using softer, smaller abrasives like polishing compounds and wheels, surface imperfections such as scratches and unwanted film/layers are removed to achieve a part’s desired texture (as different industries require different surface finishes). Polishing can be done by hand, machine, or robot, as it doesn’t require quite as much precision as grinding or deburring do. This step can be taken farther with buffing, which gives parts a finish similar to that of a mirror.

3. Deburring

This process is the act of removing burrs from a part’s surface. Burrs are extra bits of metal that form as a part is being cut, and can be extremely harmful both for a part’s functionality and the overall assembly it’s a part of. Deburring can be done by hand or in a machine, though hand deburring proves to be inconsistent and costly. The process of deburring requires extreme precision, as any leftover bit of metal can cause inconsistencies that result in the decrease of a part’s longevity and efficiency. Deburring is required for any part that has been previously machined and can be done on a variety of different materials, such as ceramic, stainless steel, wood, titanium, and more. What makes it an essential process is it ensures parts meet industry standards and helps reduce the possible formation of stress risers.

Surface Profiling

Seeing as all three of these processes fall under surface finishing, it’s important to know how surface finish is measured. Surface profiling is the measurement of a surface’s roughness, which allows manufacturers to know how adequately prepared a part is for further processing, especially when it comes to the part coating and assembly stages. A profilometer is the tool used to measure these surfaces and can be split into two categories: contact and non-contact. Contact profilometers use a stylus to map out the highs and lows of the surface (also known as peaks and valleys) which allow operators to gauge how smooth or rough a workpiece surface truly is. A non-contact profilometer uses image sensors to detect a surface’s texture. While this is the faster of the two profilometers, it’s extremely sensitive to any dirt or oil that may be coating a part’s surface.

Why does manufacturing require all three processes?

Ultimately, grinding, polishing, and deburring are all needed for the same reasons: dimensional accuracy, part efficiency, corrosion resistance, and improved functionality. All of these processes refine parts so they’re safe, functional, and meet industry standards. In other words, it’s the manufacturing equivalent of editing a piece of writing before publishing. A part might work fine enough after it’s just been cut, but without grinding, polishing, and deburring, it probably won’t fit into its assembly correctly, and it certainly won’t reach its ultimate level of efficiency and precision. The time and energy spent on these three process ensure that overall assemblies will require less maintenance, which saves operators and businesses precious time and money.

The Machine that can do it all

One of the most efficient ways of grinding, polishing, and deburring on the market is by using the MAX, an all-encompassing finishing machine sold and manufactured by James Engineering. This deburring and chamfering machine is capable of carrying out all three process concurrently. This means a part can be deburred, ground, and polished in one go. This machine also has a consistent precision unreachable by any hand-done method or other machine. The MAX makes all three processes easy and affordable, which ultimately revolutionizes any operation.

To watch the MAX in action, check out the James Engineering YouTube channel here.

To inquire more about the MAX, call (303) 444-6787 today.

Abrasives in CNC Machines

Scott Richards goes into detail about why abrasives are harmful for CNCs and how operators can avoid the unnecessary struggle that comes with using them.

Abrasives are a much-needed tool for manufacturers but can quickly become problematic when used inside CNC machines.

Unlike grinding machines, or finishing systems like the MAX, CNCs are not built with bagged filtration systems that are able to handle the loads of swarf produced during product cycles. While they might include circulatory pumps, they don’t have the necessary systems that are able flush out and rid the machine of these larger damaging particles.

Not only do the chips removed by the abrasive collect within the machine, particles from the abrasives themselves will also clog it. There’s a misconception that brushes are gentler abrasive tools and don’t shed like other abrasives, so many people will put them inside of their CNCs thinking they will be less harsh than other methods. But brushes wear down too, and that matter doesn’t just disappear—it gets ground off into a thin dust which will also settle along the bottom of the machine. These brushes use materials such as zirconia alumina, ceramic, aluminum oxide, and silicon carbide, just as other abrasive tools do.

“People think brushes are different because they don’t create sparks,” clarifies Scott Richards, Vice President of James Engineering, “but if you research [their] active ingredients you’ll see they use the exact same kind of abrasive.”

There’s a handful of materials commonly used as abrasives:

1. Zirconia

As a more rigid abrasive, zirconia tends to last longer than other materials and is capable of withstanding more intense usage and higher pressure. Due to its thickness, it is best used on tougher materials, such as stainless teel and titanium. Higher volume/intense operations tend to prefer zirconia because of its durability, even though it comes at a higher price.

2. Ceramic

Ceramic is very versatile, making it useful for a number of different operations. As an organic material, it has an extended shelf life and tends to stay sharper for a longer period of time. It’s not the ideal choice for cutting parts, but it’s perfect for operations such as deburring, grinding, polishing, etc.

3. Aluminum Oxide

This material proves to be the most commonly used abrasive. Essentially a form of sandpaper, aluminum oxide is used for more delicate materials like wood and is preferred for small-scale operations that require a gentler approach. Extremely tough and highly resistant, it’s no surprise that it’s such a popular choice.

4. Silicon Carbide

Silicon carbide is not only one of the hardest abrasives, but it’s also able to withstand extremely high temperatures. Because of this, it can be found in almost all abrasive tools (grinding wheels, stones, sandpaper, etc.) as either loose or solid material. It’s not good for cutting, but great for chamfering (in fact, James Engineering sells a line of silicon carbide wheels that work perfectly for petite chamfers specifically).

What ends up happening inside of these CNC machines is the abrasive gets trapped and stuck between their ways and slides. These mechanisms require smooth movement, and when abrasive gets stuck in the oil barrier that helps these pieces of metal slide together, it starts to eat away at them with their continuous movement. “In a way, it’s like your creating sandpaper,” says Richards, “It’s literally wearing your machine out.” As these slides continue to work despite the abrasive, operators will notice the oil barrier turn black, a classic sign that there’s already a large buildup that’s been accumulated.

“Usually when people look for a deburring machine, they’re looking for one to do lots of parts. If we’re making just a couple of parts, one sheet of Scotch-Brite will last you several days, if not one week,” Richards explains, “That’s roughly one ounce of abrasive falling under your ways and slides. One ounce isn’t a big deal. But when our customers are deburring a part every 15 seconds, that’s a whole different scenario.”

Richards provides some math as reference—“For example, I’m thinking about [a company] that uses 4 ounce grinding wheels that wear out at 50 parts, and they run 5000 parts a day. That means they go through roughly 100 grinding wheels a day, which comes out to be 400 ounces—or 25 pounds—of abrasive deburred in a machine in a day.” For CNCs, this massive volume of abrasives can become detrimental in an extremely short period of time, which ultimately ends up costing shops more due to machine repair/replacement.

When shops produce at high volumes like this, having a machine made specifically for deburring is imperative to maintaining a smooth operation. Yes, CNCs are capable of deburring, but their true strengths lie in cutting parts. So when a CNC, a cutting machine, is paired with a deburring machine, such as the MAX System, shops can produce higher quality products at higher rates.

“The MAX isn’t trying to compete with CNCs,” Richards reassures, “It is meant to compliment CNC machines by letting them do what they do best: make parts.”

One of the key differences between the MAX and a CNC is that they MAX is made to handle abrasives of all different kinds. “Our machines can use anything that anyone can throw at it,” Richards states. “Scotch-Brite, grinding wheels, brushes… we’re designed for abrasive. We’ve taken away all sensitive ways and slides, replaced them with [overhead] linear motion… the MAX is resistant to abrasive.”

Digging into that a little deeper, Richards reveals that all of the MAX’s vital components are stored in the roof and can be retracted when not needed. This means that harmful swarf is unable to collect between the different mechanics and clog up the system. “Our machines that are out in the field and have been for 10 years are still showing no signs of wear—because of the design.” The MAX is also built with special bagged filters that ensure any leftover swarf is washed out of the machine; approximately 220 gallons of wash solution are pumped through it per minute, which not only cleans out the MAX but washes off the processed parts as well, preparing them further for assembly.

Abrasive doesn’t have to be, well, abrasive against your machines—by pairing your CNC with the MAX, you not only spare your CNC the pain of unnecessary wear, but you increase production quality and quantity. The MAX was created to be a partner to CNCs, not a competitor—seeing as it is unable to cut parts itself, it needs the CNC to complete its job! The MAX takes the abrasive out of CNCs so that they can put all their focus on cutting parts with long-lasting efficiency and precision.

If you’re tired of abrasive grating on your operation, invest in the MAX. Made to handle abrasives of any kind, it won’t back down from any project you may throw at it.

To learn more about what all the MAX has to offer, click here or call us at (303) 444-6787