The Difference Between Grinding, Polishing, and Deburring

These three machining processes all seem frustratingly similar—so what makes them different from each other?

Grinding, polishing, and deburring—anybody who knows anything about the precision machining process knows that these three processes are a.) crucial, and b.) acts of surface finishing. These three processes are very similar to each other, and for decades have been making people ask the same questions: What’s the difference? And why do we need to do all three processes? Both of these questions are valid, and we have the answers to both below.

The difference between grinding, polishing, and deburring.

1. Grinding

This is the process of removing material and shaping a workpiece into its final form. Grinding can be done on a multitude of materials, such as plastic, ceramic, and many different metals (stainless steel, titanium, high-nickel alloys, etc.). In order to complete this process, grinding wheels of different abrasives are used in various machines made specifically for grinding. It’s important that the correct kind of abrasive is used, as too soft of an abrasive can’t grind a workpiece enough, while too hard of an abrasive will damage a workpiece and result in decreased part quality or scrapped part. Overall, grinding is essential because it improves a part’s surface finish, which not only provides the aesthetic many industries require, but also ensures the removal of pesky surface imperfections.

2. Polishing

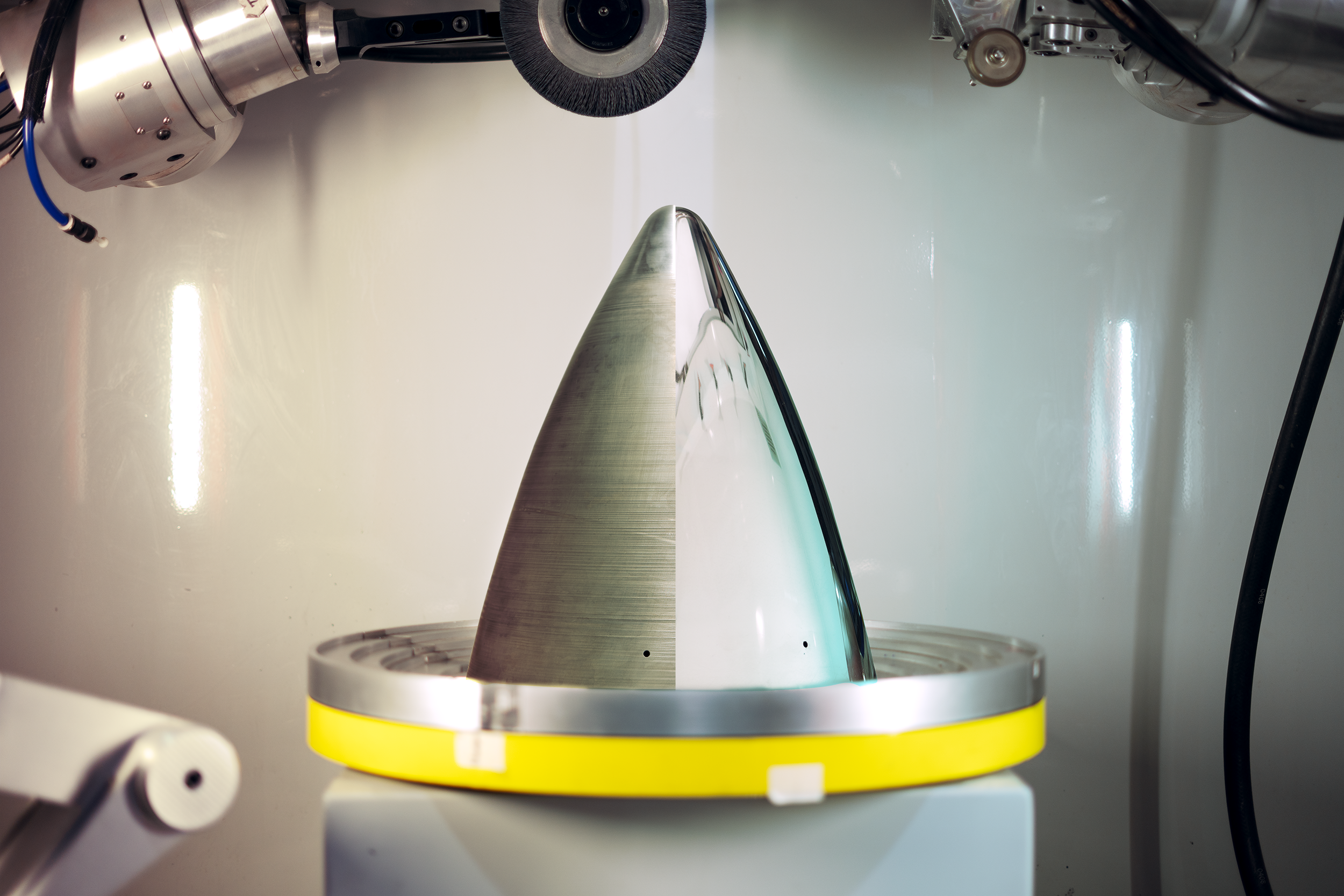

Polishing is the process surface finishing, which is also known as the process of improving surface quality. Using softer, smaller abrasives like polishing compounds and wheels, surface imperfections such as scratches and unwanted film/layers are removed to achieve a part’s desired texture (as different industries require different surface finishes). Polishing can be done by hand, machine, or robot, as it doesn’t require quite as much precision as grinding or deburring do. This step can be taken farther with buffing, which gives parts a finish similar to that of a mirror.

3. Deburring

This process is the act of removing burrs from a part’s surface. Burrs are extra bits of metal that form as a part is being cut, and can be extremely harmful both for a part’s functionality and the overall assembly it’s a part of. Deburring can be done by hand or in a machine, though hand deburring proves to be inconsistent and costly. The process of deburring requires extreme precision, as any leftover bit of metal can cause inconsistencies that result in the decrease of a part’s longevity and efficiency. Deburring is required for any part that has been previously machined and can be done on a variety of different materials, such as ceramic, stainless steel, wood, titanium, and more. What makes it an essential process is it ensures parts meet industry standards and helps reduce the possible formation of stress risers.

Surface Profiling

Seeing as all three of these processes fall under surface finishing, it’s important to know how surface finish is measured. Surface profiling is the measurement of a surface’s roughness, which allows manufacturers to know how adequately prepared a part is for further processing, especially when it comes to the part coating and assembly stages. A profilometer is the tool used to measure these surfaces and can be split into two categories: contact and non-contact. Contact profilometers use a stylus to map out the highs and lows of the surface (also known as peaks and valleys) which allow operators to gauge how smooth or rough a workpiece surface truly is. A non-contact profilometer uses image sensors to detect a surface’s texture. While this is the faster of the two profilometers, it’s extremely sensitive to any dirt or oil that may be coating a part’s surface.

Why does manufacturing require all three processes?

Ultimately, grinding, polishing, and deburring are all needed for the same reasons: dimensional accuracy, part efficiency, corrosion resistance, and improved functionality. All of these processes refine parts so they’re safe, functional, and meet industry standards. In other words, it’s the manufacturing equivalent of editing a piece of writing before publishing. A part might work fine enough after it’s just been cut, but without grinding, polishing, and deburring, it probably won’t fit into its assembly correctly, and it certainly won’t reach its ultimate level of efficiency and precision. The time and energy spent on these three process ensure that overall assemblies will require less maintenance, which saves operators and businesses precious time and money.

The Machine that can do it all

One of the most efficient ways of grinding, polishing, and deburring on the market is by using the MAX, an all-encompassing finishing machine sold and manufactured by James Engineering. This deburring and chamfering machine is capable of carrying out all three process concurrently. This means a part can be deburred, ground, and polished in one go. This machine also has a consistent precision unreachable by any hand-done method or other machine. The MAX makes all three processes easy and affordable, which ultimately revolutionizes any operation.

To watch the MAX in action, check out the James Engineering YouTube channel here.

To inquire more about the MAX, call (303) 444-6787 today.

Part Finishing 101: A Beginner's Guide

Part finishing is an in-depth process requiring multiple different applications to ensure parts are processed to perfection.

Every piece of machinery is made up of a thousand smaller pieces all continuously working together to accomplish the same goal. Every single one of these pieces need to go through the part finishing process, which ensures they work correctly and keep the overall operation running smoothly. “Part finishing” is an umbrella term for all the individual processes and techniques that go into the ultimate completion of these parts/gears.

Machining

First, let’s start with machining. This is where gears/parts are initially manufactured out of blocks of raw material. CNC (computer numerical control) machines do most of this work, and there are multiple different kinds of CNC machines, such as milling machines, lathes and turning machines, laser cutting machines, etc. Excess material is carved away by these machines to reveal the rough shape of whatever gear/prismatic part is being created. Once this first step is completed, the nitty-gritty side of part finishing begins.

Deburring

Deburring is the process of removing burrs from the edges and surfaces of these freshly cut parts/gears. Burrs are sharp bits of excess metal that will eventually ruin the integrity and overall quality of whatever part/gear they’re stuck to. This process can be done by hand, in a CNC machine, or a machine made specifically for deburring*, such as a James Engineering machine. Deburring is one of the most crucial aspects of part finishing, as many other processes cannot be done if a part or gear is not deburred properly.

Surface Grinding

This process creates smooth surface finishes on metal and non-metal parts alike. It’s an abrasive process which uses grinding wheels to shave down any surface impurities that might affect the functionality and aesthetic of a gear/part. Grinding wheels (add link to website page here) come in a variety of sizes and materials, which directly determine a wheel’s grinding intensity. Grinding surfaces are crucial when it comes to achieving tight part tolerances, as it ensures a part will fit perfectly within its environment. Surface grinding will also rid a part/gear of any corrosive layers that may negatively affect its overall durability.

Polishing

Polishing is done to further smoothen a part’s surface. What makes polishing different from surface grinding is that it’s meant to enhance surface quality, whereas grinding is used to remove extra material. Polishing is also an abrasive process, and it uses polishing pastes and abrasive pads. Polished parts are reflective and more resistant to corrosion, which makes it a crucial step in the finishing process for items such as car bumpers, medical equipment, mirrors, and more.

Buffing

Many people get buffing and polishing confused—but it’s fair considering how alike these two processes are. What makes them different is their levels of aggression. Buffing is the more aggressive of the two, and can actually remove surface material if done too hard. It can be used to remove shallow scratches, and unlike polishing, it will not leave a highly reflective surface. Buffing is frequently used in the automotive, jewelry, and electronic industries.

Chamfering

This step of the part finishing process is extremely important, especially for pieces with right-angled edges. Chamfering is when these edges are cut at a slope, which later makes assembly easier and reduces the amount of stress risers within a gear/part. Sharp, non-chamfered edges can snap and break off, leading to loose material floating throughout a machine. This debris could ultimately affect the efficiency of the entire machine, and even cause it to fail completely. When edges are chamfered, the likelihood of such an occurrence is reduced drastically. It will also ensure that pieces fit together more snugly, reducing the risk of the parts themselves becoming too loose.

Brushing

Brushing can be categorized as a type of deburring, as it can technically get rid of excess burrs left on the surfaces of parts. But that’s not its man job—brushing is used as a way to further perfect part surfaces, as it preps parts for coatings and rids them of any external contaminants, such as oils, dirt, residue, etc. It is also a very precise process in the sense that if only one small section of a part/gear needs further surfacing, a brush can stay focused on that specific spot without affecting the rest of the gear/part’s body. An important thing to remember when it comes to metal brushing is that certain brushes must be used on certain metals; for example, stainless steel can only be brushed with steel brushes. But other materials, such as rubber and leather, can also be brushed if need be.

Sandblasting

This process is also known as abrasive blasting, as it can be done with many other substances other than sand, such as glass beads, water, dry ice, and compressed air. This is another technique used to smoothen, decontaminate, and shape surfaces. This technique of part finishing comes from the naturally occurring phenomenon called aeolian erosion, which is when an environment’s geography is changed and shaped by consistent winds. Blasting is done manually when a blasting substance is mixed with air in a pressurized chamber and dispensed through an abrasive-proof handheld nozzle.

Washing

The washing process works exactly how you’d think it would—a mixture of hot water, solvent, or washing fluid are dispensed either by hand or by a machine over freshly-processed parts to clean them of excess swarf. It’s important to wash parts of debris because, as mentioned above, debris can drastically decrease the effectiveness of a part/gear and the greater machine it was assembled into. In order to avoid corrosion or rusting, special fluids must be used to protect both the part being washed and the machine doing said washing.

Overall

Machining, deburring, chamfering, washing, brushing, surface grinding, polishing, buffing, and sandblasting are the most common part finishing processes in the manufacturing industry, but there are still a variety of methods used that were not mentioned. Each process has its own unique use, and it’s crucial that manufacturers understand what method will produce the strongest outcome for a part or gear.

How James Engineering Part Finishes

Here at James Engineering, we are experts when it comes to the varying methods of part finishing. We manufacture and sell all all-encompassing surface finishing and chamfering machine known as the MAX System, and it’s got you covered completely—the MAX can deburr, chamfer, wash, brush, and even radius parts/gears of various sizes. The best part is the MAX can carry out multiple processes at once, which exponentially cuts down on processing time and leads to a higher production volume.

If you’d like to experience the effortless efficiency of a multitasking finishing fiend, contact us at Sales@James-Engineering.com and we will send you a quote!

*For being such a vital part in the finishing process, deburring machines are an extremely niche market of their own. James Engineering specializes in deburring and chamfering machines and offers a variety of systems at competitive pricing. Click here to learn more about the different kind of systems we manufacture.

The Grind Never Stops

It matters what your grinding wheels are made of.

Grinding wheels are vital in the manufacturing world—they’re how machinists polish rough edges and achieve consistent chamfers. The size and abrasiveness of these wheels very depending on what materials they’re made of. This will directly correlate with what gears/parts the wheels are used for.

Here at James Engineering, we have an extensive stock of various grinding wheels and sell them at competitive prices. Let’s get into the 3 main wheels we sell and why you need to know the difference between them.

—

1. The Woven Fiberglass Wheel

This is your typical grinding wheel made from a homogenous blend of aluminum oxide and powdered resin. The tops and bottoms of these wheels are pressed with fiberglass, which acts as a strengthening agent and ensures the wheels don’t break while spinning.

Pros: They’re quick, and they’re aggressive, meaning their time efficient and great for cutting.

Cons: They can sometimes be a little too aggressive. These wheels can cut too deeply and have an extreme tendency to bounce, as they have no dampening factor.

2. The Woven Cloth Wheel

This wheel is comprised of cotton, liquid resin, and aluminum oxide. You might be thinking, cotton, really? But it really works! Strips of cotton cloth are layered between layers of resin, and these many layers keep the wheel’s structure from falling apart.

Pros: These wheels are great for chamfering due to the fact they don’t bounce nearly as much as fiberglass wheels do since the cotton acts as a dampening agent. The fact that they’re softer, and don’t have as much bounce, means the parts/gears they’re working on can be spun at faster rates, achieving a quicker and smoother chamfer.

Cons: They’re a bit too soft for cutting. Believe it or not, cotton isn’t very sharp.

3. The Woven Carbon Fiber Wheel

This is the most unique wheel sold at James Engineering. In fact, it’s so unique and rare that we are the only ones to carry it! These wheels are made of carbon fiber and resin, and nothing more. There’s no abrasive added to them, but the carbon itself acts as a very mild abrasive.

Pros: They’re perfect for those with very niche needs. They create extremely subtle chamfers and have beautiful surfacing abilities. They’re also great to use at trade shows because they won’t tear apart gears or non-gears during demonstration.

Cons: They’re very, very gentle, so they can’t do very much. Since they have no abrasive added to them, they make cutting and grinding a drawn-out process—essentially, they’re mostly for people who need very petite chamfers.

—

Whatever your grinding needs consist of, James Engineering will help you find the most perfectly-fitting wheel. We’ll even send you a sample or two!

If you’re interested to know even more about the different kind of grinding wheels we sell, check out https://www.james-engineering.com/grinding-wheels.

Champion of Gear Chamfers

Achieving the perfect chamfer can be frustrating, as there are so many factors that could cause an uneven chamfer. James Engineering offers a couple of tips on how to become the champion of chamfers.

Getting a perfect gear chamfer is not easy. In many cases, many people aren’t even aware that it could be done better; they probably don’t even know why they aren’t seeing better results.

There are many variables that affect the outcome of a chamfer: grinding wheel speed, grinding wheel pressure, grinding wheel angle, rotary table speed, etc. Keeping all these components in mind can be a headache! Who knew such a process could be so complicated?

Well, James Engineering has a couple of tips that will help you achieve the cleanest chamfer possible:

· Make sure the grinding wheel engages the part gently. If it’s too quick in engaging, you might notice a small cloud of dust burst up from the point of contact, gouging the part in a way that is noticeable to the eye. This small cloud will contain 3 to 4 times more material removed in that single instant than what you’d see after chamfering the entire part!

· Be sure that the grinding wheel produces an even spark pattern. Any interruption in that pattern is a loss in efficiency, and can be caused when the wheel lifts and bounces back down onto the part. Whether that bounce is subtle or extreme, it will still cause a decrease in wheel life and leave you with an inconsistent chamfer.

· To eliminate heavy chamfer marks, or what we call striations, use a wheel that has natural shock-absorption, such as the wheel we sell at James Engineering. Most companies use rigid cutoff wheels made of fiberglass reinforcing material, bonded with a dense (and usually black) open-cutting resin. But we at James Engineering suggest using a reinforced open-cutting, resin-bonded wheel with shock-absorbing properties, which also happen to be a lighter color and won’t break when forced to flex slightly. The best way to see the difference between the two kind of wheels, other than overall performance, is to bounce the cutting edge of the wheel off your desk. The competing wheel will bounce instantly, while ours will absorb some of the impact’s shock and not bounce as wildly—it’ll even sound quieter!

If you implement these three tips, chamfering becomes a whole different animal. You’ll be able to hear the difference between a good and bad chamfer; the good will sound smooth, while the bad will sound choppy. You’ll be left with a chamfer so clean, so perfect, you won’t be able to help but call it the champion of all gear chamfers. If you have any questions, or would like to receive a wheel sample, please feel free to contact us at Sales@James-Engineering.com.

Rough, uneven chamfers.

Smooth, even chamfers achieved by the MAX System, the ultimate gear chamfering machine