The Future of Automation in Manufacturing | Machines vs. Human Labor

As manufacturing landscapes evolve, automation emerges as a crucial solution for optimizing processes like deburring and chamfering. This article explores the pressing need for automation in manufacturing, the challenges faced by human labor, and the limitations encountered with traditional robotic systems.

Automation in Part Manufacturing

As manufacturing landscapes evolve, automated deburring emerges as a crucial solution for optimizing processes like machine deburring and machine chamfering. This blog explores the pressing need for automated deburring, the challenges faced by human labor, and the limitations encountered with traditional robotic systems.

The Need for Automated Deburring in Part Finishing

Modern manufacturing demands high levels of efficiency and precision, especially in tasks like deburring and chamfering critical for part quality. Human labor, while skilled, faces challenges such as fatigue, variability, and safety risks. These factors hinder consistent production output and quality assurance, necessitating a shift towards automation.

Challenges of Human Labor

Limitations and Safety Concerns

Manual hand deburring and chamfering tasks are time-consuming and physically demanding, leading to potential errors and variability in results. Moreover, human operators face safety risks associated with handling sharp edges and heavy machinery, impacting both productivity and worker well-being.

Challenges of Industrial Robots

Rigidity and Adaptability

Traditional industrial robots, while efficient in certain tasks, often lack the adaptability required for complex deburring and chamfering processes. Their rigid programming limits flexibility, leading to challenges in handling diverse workpiece geometries and achieving consistent results across different parts.

Focused Deburring

Precision and Adaptability in Automated Deburring

James Engineering experts emphasize the significance of compliant technology in addressing these challenges. Their patented Focused Deburring can adapt to varying workpiece geometries, ensuring precise and consistent results without constant manual adjustments, or the need to mask parts. This adaptability reduces errors, enhances quality control, and streamlines manufacturing processes. Ensuring the next level of precision in deburring machines.

Integrating Automation for Sustainable Manufacturing

The evolution of manufacturing hinges on integrating automation solutions that combine efficiency, precision, and safety. By addressing the limitations of human labor and traditional robotic systems, manufacturers can achieve higher productivity, quality assurance, and workforce empowerment. Experts like James Engineering offer valuable insights and solutions that pave the way for a sustainable and innovative manufacturing future.

See the different system options here.

Contact us to determine which system best suits your manufacturing needs.

The Difference Between Grinding, Polishing, and Deburring

These three machining processes all seem frustratingly similar—so what makes them different from each other?

Grinding, polishing, and deburring—anybody who knows anything about the precision machining process knows that these three processes are a.) crucial, and b.) acts of surface finishing. These three processes are very similar to each other, and for decades have been making people ask the same questions: What’s the difference? And why do we need to do all three processes? Both of these questions are valid, and we have the answers to both below.

The difference between grinding, polishing, and deburring.

1. Grinding

This is the process of removing material and shaping a workpiece into its final form. Grinding can be done on a multitude of materials, such as plastic, ceramic, and many different metals (stainless steel, titanium, high-nickel alloys, etc.). In order to complete this process, grinding wheels of different abrasives are used in various machines made specifically for grinding. It’s important that the correct kind of abrasive is used, as too soft of an abrasive can’t grind a workpiece enough, while too hard of an abrasive will damage a workpiece and result in decreased part quality or scrapped part. Overall, grinding is essential because it improves a part’s surface finish, which not only provides the aesthetic many industries require, but also ensures the removal of pesky surface imperfections.

2. Polishing

Polishing is the process surface finishing, which is also known as the process of improving surface quality. Using softer, smaller abrasives like polishing compounds and wheels, surface imperfections such as scratches and unwanted film/layers are removed to achieve a part’s desired texture (as different industries require different surface finishes). Polishing can be done by hand, machine, or robot, as it doesn’t require quite as much precision as grinding or deburring do. This step can be taken farther with buffing, which gives parts a finish similar to that of a mirror.

3. Deburring

This process is the act of removing burrs from a part’s surface. Burrs are extra bits of metal that form as a part is being cut, and can be extremely harmful both for a part’s functionality and the overall assembly it’s a part of. Deburring can be done by hand or in a machine, though hand deburring proves to be inconsistent and costly. The process of deburring requires extreme precision, as any leftover bit of metal can cause inconsistencies that result in the decrease of a part’s longevity and efficiency. Deburring is required for any part that has been previously machined and can be done on a variety of different materials, such as ceramic, stainless steel, wood, titanium, and more. What makes it an essential process is it ensures parts meet industry standards and helps reduce the possible formation of stress risers.

Surface Profiling

Seeing as all three of these processes fall under surface finishing, it’s important to know how surface finish is measured. Surface profiling is the measurement of a surface’s roughness, which allows manufacturers to know how adequately prepared a part is for further processing, especially when it comes to the part coating and assembly stages. A profilometer is the tool used to measure these surfaces and can be split into two categories: contact and non-contact. Contact profilometers use a stylus to map out the highs and lows of the surface (also known as peaks and valleys) which allow operators to gauge how smooth or rough a workpiece surface truly is. A non-contact profilometer uses image sensors to detect a surface’s texture. While this is the faster of the two profilometers, it’s extremely sensitive to any dirt or oil that may be coating a part’s surface.

Why does manufacturing require all three processes?

Ultimately, grinding, polishing, and deburring are all needed for the same reasons: dimensional accuracy, part efficiency, corrosion resistance, and improved functionality. All of these processes refine parts so they’re safe, functional, and meet industry standards. In other words, it’s the manufacturing equivalent of editing a piece of writing before publishing. A part might work fine enough after it’s just been cut, but without grinding, polishing, and deburring, it probably won’t fit into its assembly correctly, and it certainly won’t reach its ultimate level of efficiency and precision. The time and energy spent on these three process ensure that overall assemblies will require less maintenance, which saves operators and businesses precious time and money.

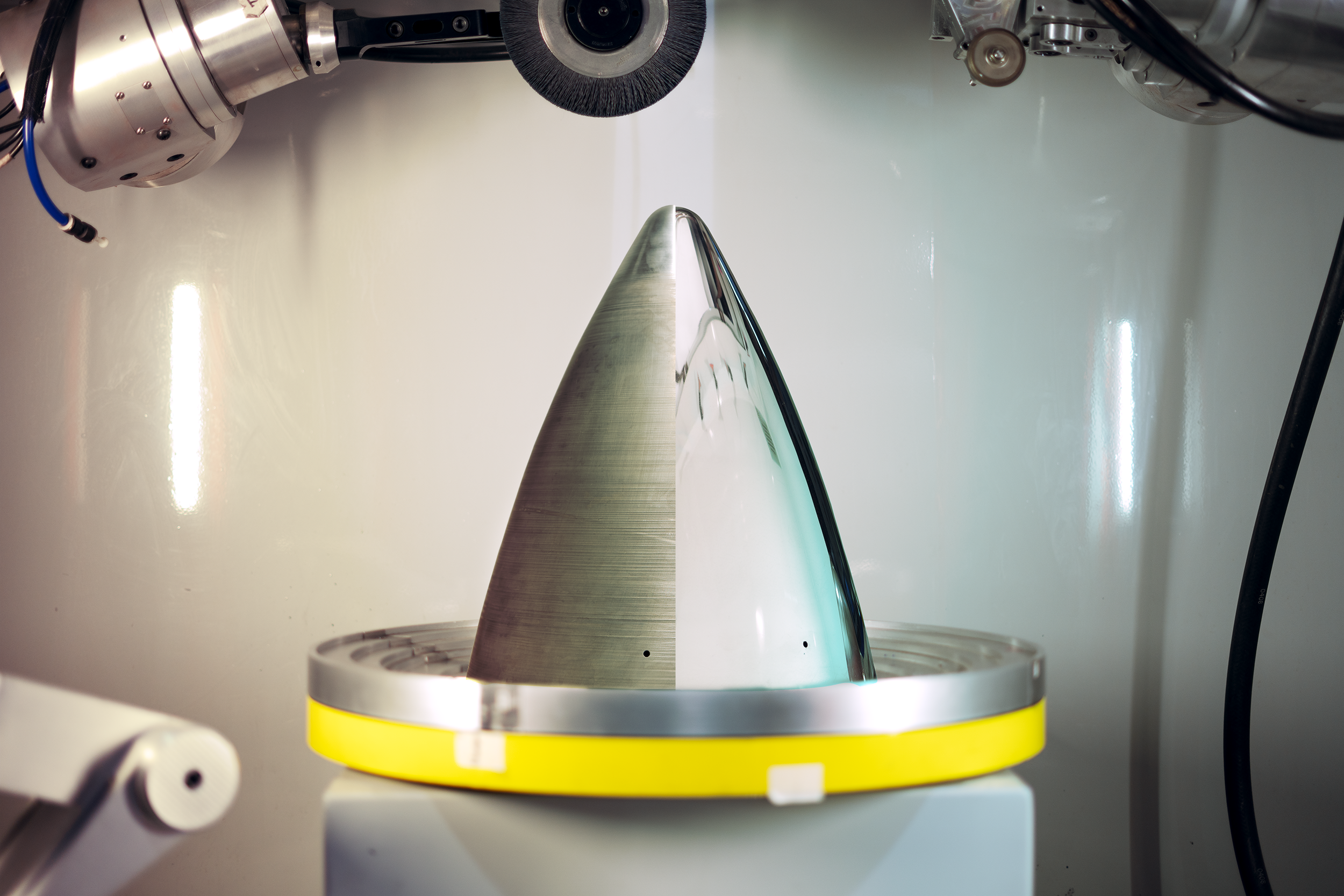

The Machine that can do it all

One of the most efficient ways of grinding, polishing, and deburring on the market is by using the MAX, an all-encompassing finishing machine sold and manufactured by James Engineering. This deburring and chamfering machine is capable of carrying out all three process concurrently. This means a part can be deburred, ground, and polished in one go. This machine also has a consistent precision unreachable by any hand-done method or other machine. The MAX makes all three processes easy and affordable, which ultimately revolutionizes any operation.

To watch the MAX in action, check out the James Engineering YouTube channel here.

To inquire more about the MAX, call (303) 444-6787 today.

Types of Deburring

Let’s dive in to eight different methods of deburring!

Punch Deburring

Since its perfection in 1770, sheet metal has become a commonly used material within the manufacturing world. One of the most popular ways of cutting and manipulating sheet metal is a method called “punching”. A punch machine uses interchangeable tools to cut out shapes from the sheet metal, and it’s vital that these tools are sharp. If they aren’t, they require more force to cut through the metal, which can lead to the formation of burrs. Punch machines can deburr the pieces of sheet metal they just cut, and they do so with another set of interchangeable tools, which are meant for deburring. This method of deburring works well for pieces cut from sheet metal, but it’s extremely limited when it comes to parts with complex geometries.

Tumbling Deburring

This method involves parts/gears being tumbled in a barrel full of water and loose materials (known as tumbling media), such as glass beads, steel, or plastic. The force of the material and parts tumbling against each other will break off any present burrs and smooth out a part’s surface. Operators must be able to choose their media correctly, as some will do extreme damage to gears/parts made of other certain materials. For instance, steel parts must be paired with steel material. Tumbling is a good option for larger parts/gears, as it is a quicker way to remove their burrs compared to doing it by hand, and they are less likely to suffer overall structural damage from it. However, that risk is still there, and it can ultimately do more harm than good.

Vibratory Deburring

Vibratory deburring is like the tumbling method in the sense that parts are put into a barrel with tumbling media, but it’s more effective and gentler than its cousin method. When the loose material is vibrated against parts/gears, the force shears off burrs and other imperfections with equal force, making it a safe method for smaller, more delicate parts. This process is used frequently within industries such as the aerospace or medical industries and can even be used for parts made of wood or plastic.

Cryogenic Deburring

The cryogenic deburring method is similar to freezing off a wart. Parts are put into low-temperature chambers, where burrs are then frozen until brittle. The burrs will then get knocked off part surfaces when non-abrasive media is thrown into the chamber. This process doesn’t leave residue and preserves the surfaces of parts of any size. It’s a good option for processing large amounts of parts/gears at once, but it still lacks the precision that is necessary for complex parts.

Hand Deburring

This might be the most common—and the most time consuming—deburring method out there. Workers use handheld tools to manually complete processes such as brushing, edging, chamfering, polishing, and of course deburring. While this method allows for focused precision, workers are limited to working on one part at a time, making it extremely inefficient for high or medium volume shops. These workers also require adequate training and experience, seeing as one mistake can scrap an entire part; a little too much material taken off a part/gear can cause it to not fit into its greater assembly properly and affect its long-term efficiency. Another issue with hand deburring is that consistent chamfers are hard to achieve with it, and chamfers of poor quality will also affect the function of a larger assembly. Some manufacturers still prefer hand deburring to other methods, but it costs too much time and money to be used widely.

Electrochemical Deburring

Electrochemical deburring is a unique method of deburring that shoots currents of voltage between a cathode and a burr, ultimately dissolving said burr. This process can remove any sort of excess unwanted surface material. It’s important to maintain a gap between the cathode and part needing deburring, as this gap (paired with an electrolyte solution) allow for the transfer of voltage. It’s much more precise compared to methods such as punch deburring or tumbling deburring, and allows holes, cross holes, and intersections to be deburred easily. However, this method is limited to a small variety of materials seeing as some don’t contain the required levels of conductivity.

Thermal Deburring

The thermal deburring technique is carried out by placing parts in a pressurized chamber and setting off a series of controlled combustions, which essentially melt off any burrs or surface imperfections. The overall structure of the part/gear in the chamber isn’t harmed due to how momentary these mini explosions are, however the risk of excessive heat damage is still present. Once the burrs are removed, the part/gear is left with a thin film coating its surface and it must be cleared off before it is further processed. While efficient when it comes to removing multiple burrs/surface imperfections at once, it also lacks the necessary precision required by some industries, such as the aerospace industry.

Machine Deburring

Machine deburring is the most effective method of deburring when it comes to timeliness, cost efficiency, and precision, and has been gaining popularity as the demand for all three of these factors has grown dramatically over the course of the last few years. Machine deburring extends to both CNC machines and finishing machines, such as the MAX System from James Engineering, a high precision deburring and chamfering machine. CNC machines are most efficient when it comes to cutting parts, but they also have limited deburring capabilities. The MAX System and its one-of-a-kind technologies allows the machine to deburr and chamfer, radius, wash, and brush a part concurrently. This is due to its multi-tooling feature, which is customizable to any company’s needs. It also features an 11-axis overhead gantry system, making any angle reachable. The MAX is a great option for both parts and gears of any size and any complexity, and with Focused Deburring (a technology unique to James Engineering), burrs can be targeted—something only James Engineering finishing systems are capable of.

Which one is right for you?

These eight methods of deburring are used for a wide range of industries, parts, and gears, and each have their own pros and cons. Finding the right one for your company ultimately depends on the volume at which your shop is producing, and what parts/gears you produce. The lower your shop’s volume is, and the simpler your parts, methods such as hand deburring can be a reasonable choice. If your shop is producing at a high volume and working with a wide array of gears/parts of a variety of materials, a specialized finishing machine such as the MAX System is the most time and cost-effective move to make. Doing your own research is important, and you know your shop’s needs the best… but you can never go wrong with the MAX.