What is Gear Hobbing?

Understanding Gear Hobbing and Deburring in Manufacturing. What is Gear Hobbing? Gear hobbing is a machining process used to cut gears, splines, and sprockets. What is the Difference Between Gear Cutting and Hobbing? Why is it Important to Remove Burrs? What is the Effect of Deburring?

We answer ALL your questions!

Understanding Gear Hobbing and Deburring in Manufacturing

In manufacturing, precision and efficiency reign supreme. At the heart of achieving these goals are understanding two pivotal processes: gear hobbing and deburring. This article will explore what gear hobbing is, distinguish it from gear cutting, and delve into the importance of removing burrs and the effects of deburring.

What is Gear Hobbing?

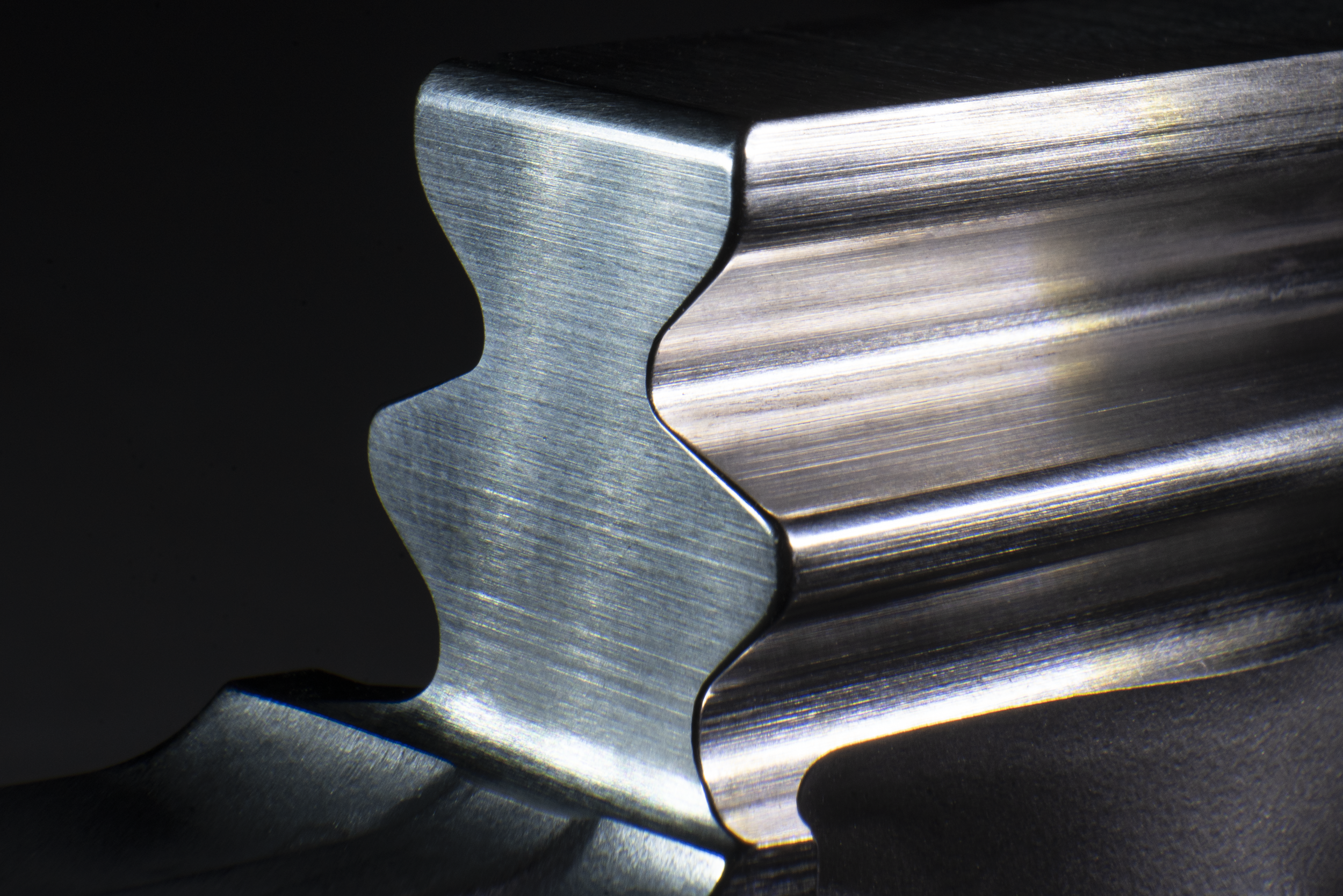

Gear hobbing is a machining process used to cut gears, splines, and sprockets. It involves using a specialized cutting tool known as a hob, which rotates continuously while being fed into the workpiece to progressively carve out the gear teeth. This process is highly efficient and can produce a wide range of gear sizes and shapes with high precision. Gear hobbing is commonly used in the automotive, aerospace, and machinery industries due to its ability to produce high-quality gears at a relatively low cost.

What is the Difference Between Gear Cutting and Hobbing?

While gear hobbing is a type of gear cutting, not all gear cutting processes are hobbing. Gear cutting is a broad term that encompasses various methods used to create gear teeth, including hobbing, shaping, milling, and broaching.

Gear Hobbing: Utilizes a hob and is suitable for producing both spur and helical gears. It is known for its efficiency and versatility in creating various gear profiles.

Gear Shaping: Uses a reciprocating cutter to cut the gear teeth. It is particularly useful for internal gears and gears with complex shapes.

Gear Milling: Involves using a milling machine and a form cutter to create the gear teeth. This method is typically used for small production runs or prototype gears.

Gear Broaching: Uses a toothed tool called a broach to cut the entire gear profile in a single pass. It is ideal for producing large quantities of gears quickly.

Each of these methods has its advantages and specific applications, but gear hobbing is often favored for its combination of speed, precision, and versatility.

Why is it Important to Remove Burrs?

Burrs are unwanted, rough edges or protrusions that remain on metal parts after machining processes such as cutting, drilling, or grinding. These burrs can have several detrimental effects if not removed:

Safety Hazards: Burrs can cause injuries to workers handling the parts.

Assembly Issues: Burrs can interfere with the proper fitting and functioning of parts in assemblies.

Performance Problems: Burrs can affect the performance and longevity of mechanical components, leading to increased wear and tear or even failure.

Aesthetic Concerns: Burrs can negatively impact the appearance of the final product.

Why is Deburring Necessary?

Deburring is the process of removing burrs from metal parts. It is a crucial step in the manufacturing process for several reasons:

Enhances Safety: By removing sharp edges, deburring prevents potential injuries to workers and end-users.

Improves Functionality: Deburred parts fit together more precisely, ensuring proper assembly and optimal performance of mechanical systems.

Extends Product Life: Deburring reduces friction and wear, which can extend the lifespan of components.

Ensures Quality: Removing burrs improves the overall quality and appearance of the product, making it more attractive to customers and less likely to be returned due to defects.

What is the Effect of Deburring?

The effects of deburring extend beyond mere aesthetics and safety. Deburring can significantly impact the overall quality and performance of manufactured parts. Here are some key effects:

Enhanced Durability: By eliminating stress concentrations that can lead to cracks or failures, deburring contributes to the structural integrity of components.

Improved Precision: Deburred parts have cleaner edges and more accurate dimensions, which is critical for applications requiring high precision.

Better Surface Finish: The removal of burrs results in a smoother surface finish, which can improve the part's functionality and reduce the risk of corrosion.

Increased Efficiency: Parts that fit together properly reduce the likelihood of mechanical failures and downtime, leading to more efficient operation of machinery and equipment.

In conclusion, gear hobbing and deburring are essential processes in the manufacturing industry. Gear hobbing allows for the efficient and precise production of gears, while deburring ensures the safety, functionality, and quality of the final products. Understanding these processes and their significance helps manufacturers produce high-quality components that meet the rigorous demands of various industries.

What Is Gear Chamfering?

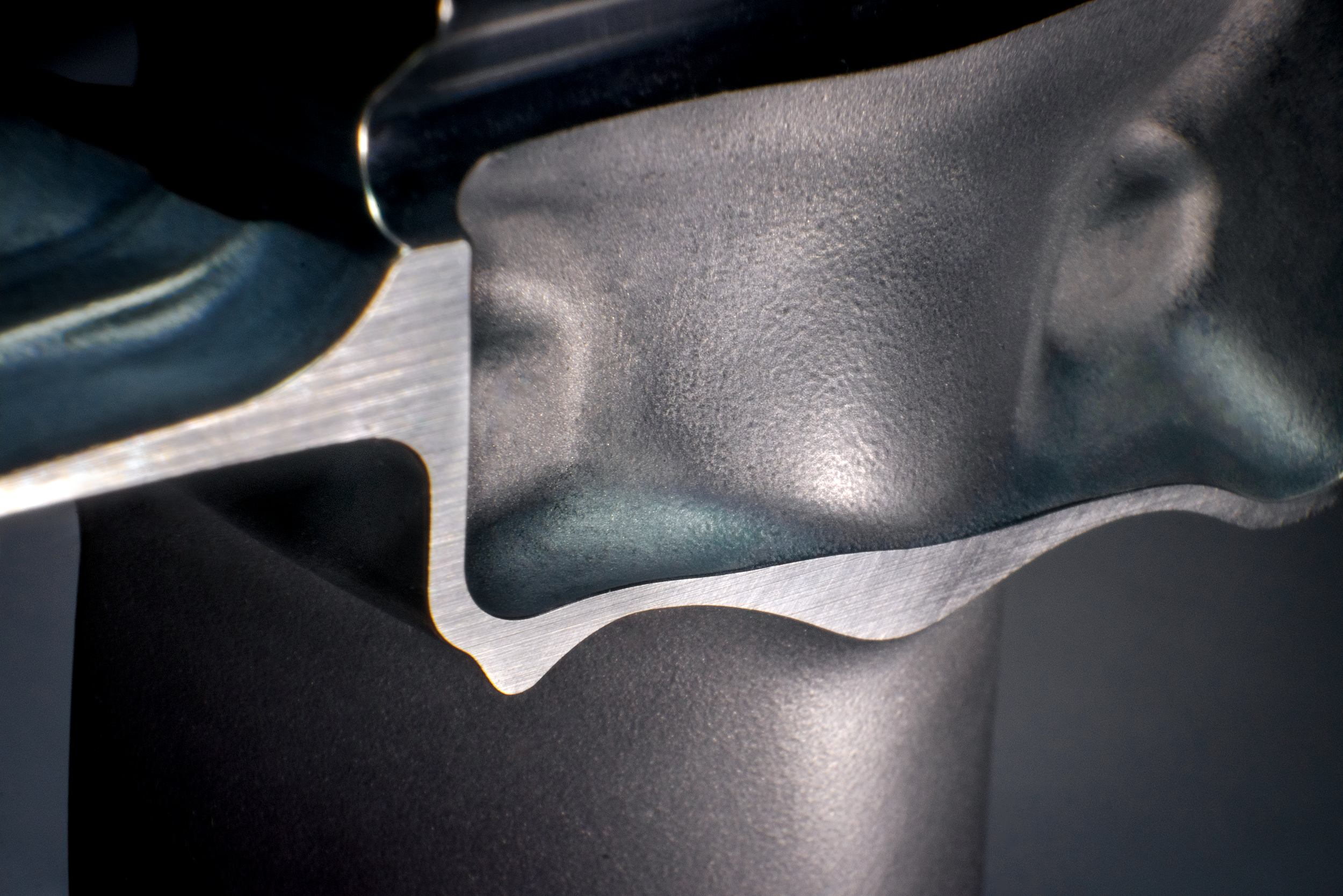

In simple terms, gear chamfering is the process of cutting a 90-degree edge at a 45-degree angle, but in reality it’s a bit more complicated than that.

Simply put, the process of chamfering is cutting a 90-degree edge at a 45-degree angle as a way to remove stress-rising sharp edges, as well as allow for smoother assembly. That makes chamfering sound easy, when in reality it’s actually very time consuming, no matter the method of approach.

Gear Chamfering can truly be broken down into four separate surface-finishing processes: deburring, chamfering, radiusing, and radius-chamfering.

- Deburring is the process of grinding off burrs, which are bits of excess metal created in the metal cutting process. Burrs are extremely problematic and will cause issues in assembly as well as overall part efficiency. Assuming the deburring has been done properly, all burrs will have been completely removed, leaving nothing but a sharp edge.

- Chamfering, as stated above, is the process of cutting that sharp edge at a 45-degree angle (which is the most common angle, but not the only one they’re limited to). Chamfering can be done with a myriad of tools, such as brushes, sandpaper, grinding wheels, and Scotch-Brite. However, in the process of shaving down this one sharp edge, two more are created on either side of the original, and if the tool being used is worn down, burrs can be created as well.

- Radiusing is the process of completely rounding out edges until it’s completely smooth. While chamfering is smoother than just leaving a part deburred, it still is cut at a noticeable angle that can be seen and felt. Radiusing feels and looks rounded (just like how a ball is round without any hard edge), and can also be carried out via brushes, grinding wheels, and sandpaper. It’s crucial to know what materials these tools are made out of, because the materials will affect the quality of the radius; if a material is too abrasive, it will be impossible to reach a true radius. A true radius is when the edges of a 90-degree angle go tangent to tangent without any surface imperfection.

- Radius-chamfering is when a part receives both radiusing and chamfering. The sharp angle is cut at the usual 45-degree angle, and when those two extra sharp angles are created, they are radiused to create smooth transitions between chamfers.

When it comes to how chamfering is done, there’s a few methods operators can choose from—machine-based, hand-based, or robot-based.

Different types of gear chamfering machines are capable of different sub-categories of chamfering. For example, a CNC machine can decently deburr a part, a lathe can adequately radius-chamfer a part, and a mill can chamfer a part. All of these options are valid, but not a single one of them can chamfer, deburr, and radius a part; separate machines are needed. Not only that, but these kinds of machines require in-depth programming for every single part in order to be exact. The MAX by James Engineering is capable of carrying out all four chamfering processes with heightened precision, as well as little programming.

Doing any of these processes by hand is technically achievable, but it ultimately proves to be more troublesome than it’s worth. Manufacturing is an industry that requires precision, as things will fall apart and fail to work correctly without it, and doing these processes by hand simply does not provide adequate enough precision. Even the best operator can slip or tremble, and man cannot repeatably guarantee a consistent chamfer. Hand chamfering is acceptable in a pinch, especially if only one or a handful of parts require it. But for higher volume operations, not only does hand chamfering not produce consistent results, it also is extremely time and cost inefficient. Scrap rates are the highest with hand chamfering, and the time it takes operators to complete one part is what it would take a CNC to do two or three, or the MAX to do a hundred.

Robots are only slightly better at gear chamfering than when done by hand. While they do have better mobility than most machines, they lack precision. Robots are perfect for operations that require the moving and placing of items, but they just cannot match a machine’s precision. Robots also require a lot of laborious programming, overall making them a poor method of chamfering.

Out of all these methods, the MAX is hands down the most reliable and efficient. As an all-encompassing finishing system, it is capable of deburring, chamfering, radiusing, and radius-chamfering any part or gear, no matter its complexity. It does require some initial programming, but once a part/gear has been loaded in, the MAX will remember it for future use, meaning operators no longer have to manually input adjustments themselves (James Engineering calls these programs “recipes”). The MAX is also capable of repeatable precision down to the fifth decimal. For reference, the average human hair measures to .003 inches. The MAX can repeatably work down to .00001 inches, and even beyond that.

Precision in chamfering is key, because the less precise a chamfer is, it’s more likely that stress risers will appear with continual usage. Stress risers are tiny cracks that form at a part/gear’s weakest point of contact (like the tooth on a gear). If a part is not adequately deburred or chamfered, what will happen is those sharp edges will slowly break off until a part or gear’s structure is ultimately compromised. So that previously mentioned tooth could fall off, for instance. That is extremely dangerous, both for the assembly itself and the people operating it. For example, a helicopter would crash if one of the gears in its motor failed. When it comes to chamfering, the higher the precision, the better. The precision achieved by the MAX means that parts/gears processed through it are extremely unlikely to form stress risers even after years of use.

There’s a misconception about chamfering that it’s done easily. Even with an advanced machine such as the MAX, chamfering is no “easy” feat. If a chamfering operation appears to be “easy”, it’s probably being done sloppily and inefficiently—and precision takes time and effort.

Knowing the correct way to chamfer is a gamechanger with any operation, as well as being able to recognize when a chamfer is done correctly. If it is, parts will fit together with no resistance and work efficiently for the entirety of their lifetime. And when parts work correctly, overall assemblies will perform at their best.

To visibly see how chamfering is done, watch a short video clip here.

To contact James Engineering about the MAX’s chamfering abilities, call at (303) 444-6787