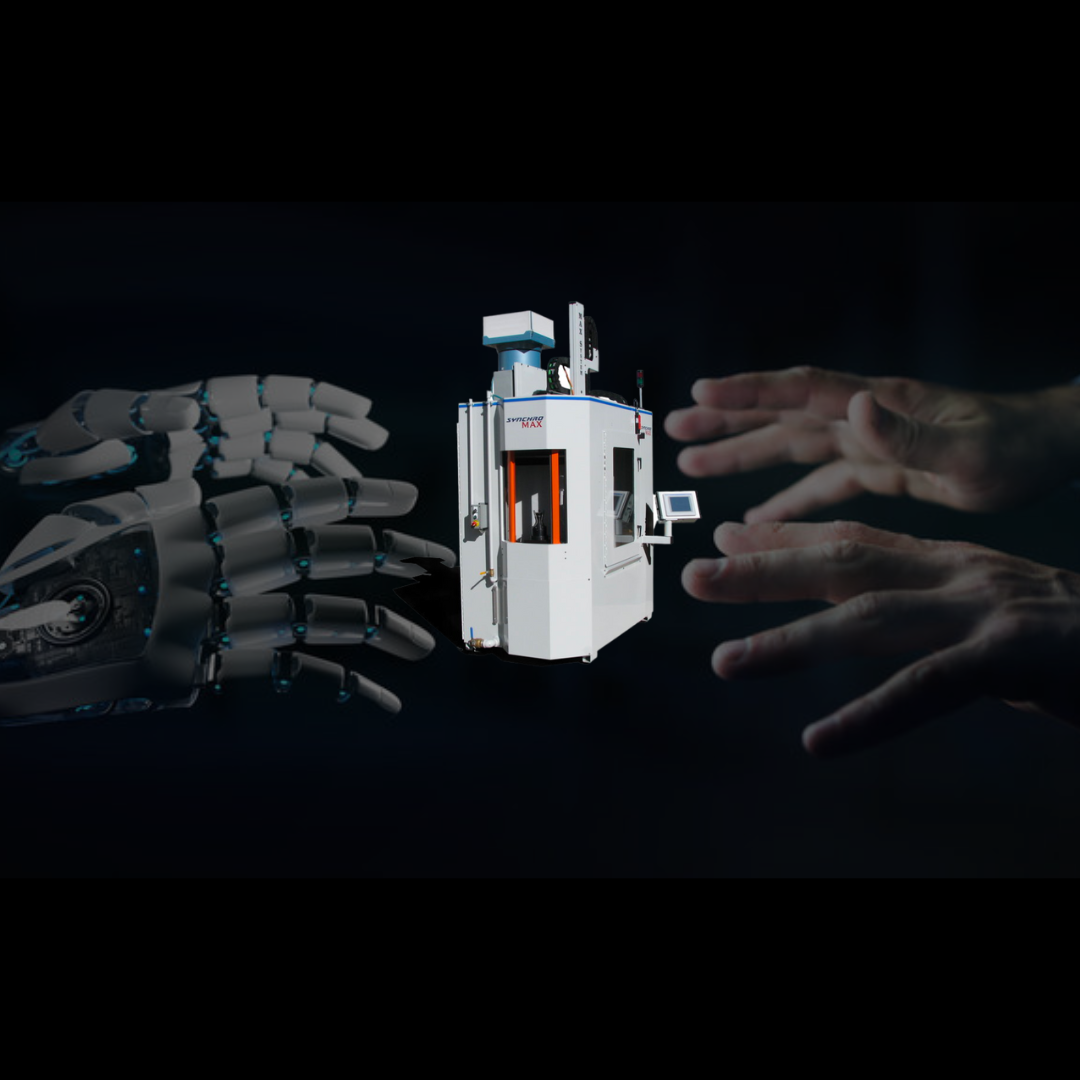

The Future of Automation in Manufacturing | Machines vs. Human Labor

As manufacturing landscapes evolve, automation emerges as a crucial solution for optimizing processes like deburring and chamfering. This article explores the pressing need for automation in manufacturing, the challenges faced by human labor, and the limitations encountered with traditional robotic systems.

Automation in Part Manufacturing

As manufacturing landscapes evolve, automated deburring emerges as a crucial solution for optimizing processes like machine deburring and machine chamfering. This blog explores the pressing need for automated deburring, the challenges faced by human labor, and the limitations encountered with traditional robotic systems.

The Need for Automated Deburring in Part Finishing

Modern manufacturing demands high levels of efficiency and precision, especially in tasks like deburring and chamfering critical for part quality. Human labor, while skilled, faces challenges such as fatigue, variability, and safety risks. These factors hinder consistent production output and quality assurance, necessitating a shift towards automation.

Challenges of Human Labor

Limitations and Safety Concerns

Manual hand deburring and chamfering tasks are time-consuming and physically demanding, leading to potential errors and variability in results. Moreover, human operators face safety risks associated with handling sharp edges and heavy machinery, impacting both productivity and worker well-being.

Challenges of Industrial Robots

Rigidity and Adaptability

Traditional industrial robots, while efficient in certain tasks, often lack the adaptability required for complex deburring and chamfering processes. Their rigid programming limits flexibility, leading to challenges in handling diverse workpiece geometries and achieving consistent results across different parts.

Focused Deburring

Precision and Adaptability in Automated Deburring

James Engineering experts emphasize the significance of compliant technology in addressing these challenges. Their patented Focused Deburring can adapt to varying workpiece geometries, ensuring precise and consistent results without constant manual adjustments, or the need to mask parts. This adaptability reduces errors, enhances quality control, and streamlines manufacturing processes. Ensuring the next level of precision in deburring machines.

Integrating Automation for Sustainable Manufacturing

The evolution of manufacturing hinges on integrating automation solutions that combine efficiency, precision, and safety. By addressing the limitations of human labor and traditional robotic systems, manufacturers can achieve higher productivity, quality assurance, and workforce empowerment. Experts like James Engineering offer valuable insights and solutions that pave the way for a sustainable and innovative manufacturing future.

See the different system options here.

Contact us to determine which system best suits your manufacturing needs.

CASE STUDY: Manufacturing Customer Survey Finds The Following Results

In 2011, we conducted a client survey of over 1500 manufacturers, across varied industries doing manual and hand deburring.

How Much Production Time Are You Losing?

Set up? Processing Time? The MAX speeds all of this!

FASTEST CHANGE OUTS:

This doesn’t even include the faster processing time of each part... If you deburr 250 parts a month, you could save approximately 120 hours in setup time alone.

How much production time are you losing?

Set up? Processing Time? The MAX speeds all of this!

Once a setup is made, it is saved as a recipe.

Recipes are called up by filename instantly.

No Changeover or setups!

*As an option, we also offer auto-part ID.

Lower your Cost Per Part!

The MAX Systems are ideal for applications where parts are run on a repeat basis. The frequency and

volume is not important. In other words, you can run a different part every single cycle as long as

the parts are re-run at some point; even if it is five years down the road. Your saving yourself time and money!

Fastest Cycle Times in the Biz!

Run a different part every cycle!

Automatic Wheel Wear Compensation

Chamfer, Radius or any other type of edge finish

It has been about five years since we bought your deburring machine. I can boast that we have greatly improved the quality of gears as opposed to hand deburring. The productivity is unmatched! Many of the parts used to take 30 minutes by hand and now the same part is done in about 30 sec.

— Ramdas Amin, Mfg Engineer, GE Aviation Systems

I have been using a James Engineering 462 for about 4 years now. It works wonderful I can’t imagine working without that machine. It has done our company justice!

— Tim Fuller, Manufacturing Engineer, Baldor

We have benefited from faster set-up times to faster cycle times. The machine has functioned effectively without failure ever since we powered it up in 2005.

It is extremely easy to set up on spiral bevel ring gears and many other parts we manufacture.

We highly recommend it for any company interested in improving their deburring processes

— Paul Campion, GM, Reliance Gear

See more of our customers here.

Maximizing Efficiency: How Automated Deburring Systems Revolutionize Manufacturing

In the fast-paced world of modern manufacturing, the quest for efficiency is relentless. Every step in the production process must be optimized to meet the demands of precision, speed, and cost-effectiveness. One area where significant strides have been made is in the realm of deburring, and the introduction of automated deburring systems has revolutionized the manufacturing landscape. This article delves into the transformative impact of automated deburring, exploring its benefits, applications, and how it has become a cornerstone for maximizing efficiency in diverse industries.

In the fast-paced world of modern manufacturing, the quest for efficiency is relentless. Every step in the production process must be optimized to meet the demands of precision, speed, and cost-effectiveness. One area where significant strides have been made is in the realm of deburring, and the introduction of automated deburring systems has revolutionized the manufacturing landscape. This article delves into the transformative impact of automated deburring, exploring its benefits, applications, and how it has become a cornerstone for maximizing efficiency in diverse industries.

The Evolution of Deburring:

Deburring, once a manual and time-consuming process, has undergone a remarkable evolution with the integration of automation. Traditionally, workers meticulously removed burrs and sharp edges from machined components, a task that was not only labor-intensive but also prone to variations in quality. Automated deburring systems have emerged as a game-changer, offering a streamlined and consistent approach to this crucial manufacturing step.

Benefits of Automated Deburring Systems:

Precision and Consistency:

Automated deburring systems provide unparalleled precision, ensuring that every component is treated with the same level of accuracy. This consistency is vital in industries where even the slightest deviation from specifications can lead to performance issues or product defects.

Time Efficiency:

Time is of the essence in manufacturing, and automated deburring significantly reduces cycle times. The swift and continuous operation of robotic systems allows for a faster throughput of components, contributing to overall production efficiency.

Labor Cost Savings:

The automation of deburring processes translates into reduced labor costs. Manufacturers can reallocate human resources to more intricate tasks, while automated systems handle the repetitive and time-intensive nature of deburring.

Enhanced Safety:

Manual deburring poses risks to workers due to sharp edges and repetitive motion injuries. Automated systems eliminate these safety concerns, creating a safer working environment and reducing the likelihood of workplace accidents.

Applications Across Industries:

Automated deburring systems find applications in a myriad of industries, from aerospace and automotive to electronics and medical device manufacturing. The versatility of these systems allows them to adapt to various materials, geometries, and part sizes, making them an invaluable asset in diverse production environments.

Technological Advancements:

The 11-Axis MAX system has further enhanced the capabilities of automated deburring systems, taking them next level. Intelligent and easy to use, these systems adapt to different materials and geometries, optimizing the deburring process for each unique component.

Case Studies:

Several manufacturing leaders have reported substantial improvements in efficiency, quality, and cost savings after implementing automated deburring systems. Real-world examples showcase how these systems have become a cornerstone of lean manufacturing practices, driving competitiveness in the global market.

The integration of automated deburring systems represents a transformative leap forward in manufacturing efficiency. As industries continue to push the boundaries of innovation, automated deburring emerges as a key player, ensuring that components meet stringent quality standards while optimizing production processes. Manufacturers embracing these advanced systems are not just keeping pace with the demands of the market; they are setting new standards for efficiency and reliability in the modern era of manufacturing.

To learn more about what all the MAX has to offer, email us or call us at (303) 444-6787

Deburring and Part Finishing in the Aerospace Sector: Exceeding Industry Standards

In the dynamic world of aerospace engineering, precision and quality are paramount. Every component, no matter how small, plays a crucial role in the overall performance and safety of an aircraft. One often overlooked but essential process in aerospace manufacturing is deburring and part finishing. This article explores the significance of deburring, its role in meeting industry standards, and the latest techniques employed by top engineers in the aerospace sector.

In the dynamic world of aerospace engineering, precision and quality are paramount. Every component, no matter how small, plays a crucial role in the overall performance and safety of an aircraft. One often overlooked but essential process in aerospace manufacturing is deburring and part finishing. This article explores the significance of deburring, its role in meeting industry standards, and the latest techniques employed by top engineers in the aerospace sector.

Apache Longbow manufactured by Boeing

Understanding Deburring:

Deburring is the process of removing unwanted rough edges, burrs, or imperfections from machined or manufactured parts. In aerospace, where precision is non-negotiable, deburring ensures that components fit seamlessly together, reducing the risk of mechanical failure and enhancing overall efficiency.

Importance in Aerospace Manufacturing:

Aerospace components undergo intricate machining processes, leaving behind sharp edges and burrs. These imperfections can compromise the structural integrity of the parts and, consequently, the entire aircraft. Deburring is not merely a cosmetic enhancement; it is a critical step in maintaining the safety and reliability of aerospace systems.

Industry Standards:

The aerospace industry adheres to rigorous standards and regulations to ensure the highest level of safety and performance. Deburring plays a pivotal role in meeting these standards, as components must not only meet precise dimensional specifications but also undergo thorough inspection to eliminate any defects that could compromise the integrity of the final product.

an aerospace finish does not allow for any

grinding marks

surface blemishing

surface scratches

any jagged edges

inconsistencies and so on.

since most parts are “life critical”,

THE AEROSPACE INDUSTRY demands perfection.

F-22 Raptor Lockheed Martin/Boeing

Latest Techniques in Aerospace Deburring:

As technology advances, so do the techniques employed in aerospace deburring. Top aerospace and defense producers now utilize state-of-the-art equipment, such as The MAX, an 11-axis multi-finishing system that offers unparalleled accuracy, consistency, and speed in finishing processes. The use of the patented Focused Deburring, ensures that even the most intricate components can be deburred with precision, meeting the stringent requirements of aerospace applications. While also contributing to increased efficiency and cost-effectiveness in the overall manufacturing process.

THE MAX

11-Axis Advanced Multi-Finishing System

Equipped with up to 4 different precision finishing tools has revolutionized the aerospace and defense industry.

In the demanding field of aerospace engineering, every detail matters. Deburring and part finishing are essential steps in ensuring the integrity, safety, and performance of aerospace components. As technology continues to evolve, top manufacturers will continue to embrace innovative solutions to meet and exceed industry standards. The combination of precision, automation, and advanced methods propels aerospace manufacturing into a future where safety and quality are never compromised.

To learn more about The MAX click here.

If you’re interested in learning how to improve your own finishing process, give James Engineering a call at (303) 444-6787, or email us at Sales@James-Engineering.com.

Mastering Precision: A Comprehensive Guide to Overcoming Part Finishing Challenges

In the intricate realm of manufacturing, achieving precision in part finishing is an ongoing pursuit that directly influences the quality and functionality of the final product. This comprehensive guide explores the common challenges encountered in part finishing and offers valuable insights into overcoming these hurdles with the help of advanced deburring and chamfering machines.

In the intricate realm of manufacturing, achieving precision in part finishing is an ongoing pursuit that directly influences the quality and functionality of the final product. This comprehensive guide explores the common challenges encountered in part finishing and offers valuable insights into overcoming these hurdles with the help of advanced deburring and chamfering machines. Let's embark on a journey to master precision in part finishing.

1. Unwanted Burrs and Sharp Edges

Challenge:

Unwanted burrs and sharp edges can compromise functionality and aesthetics.

Solution: Unwanted burrs and sharp edges can be effectively removed through various methods. Manual tools like files, abrasive brushes, and rotary deburring tools offer precision, while techniques such as abrasive blasting, chemical deburring, and thermal methods provide automated solutions. Advanced approaches like electrochemical deburring, cryogenic methods, waterjet cutting, and laser deburring cater to specific needs, emphasizing the importance of selecting the most suitable method based on material, part complexity, and production requirements.

Additional Insights:

2. Inconsistent Surface Finish:

Challenge:

Achieving a consistent surface finish is crucial for quality standards.

Solution: Achieving a consistent surface finish is crucial for quality standards because it directly impacts the appearance, functionality, and performance of a finished product. Consistency ensures uniformity in texture and appearance, which is especially important in industries where aesthetics matter, such as automotive, aerospace, or consumer electronics. Additionally, a consistent surface finish is indicative of precision and attention to detail in manufacturing processes, reflecting a higher level of quality and meeting the stringent standards expected by customers and industry regulations. In applications where friction, wear, or corrosion resistance are critical factors, a uniform surface finish is essential for optimal performance and longevity of the final product. Overall, consistency in surface finish contributes to the reliability, durability, and overall quality of the manufactured components or products.

Additional Insights:

Multi-axis deburring and chamfering machines, like the 11-Axis MAX provide control for a uniform finish, meeting specifications.

Large Batch Consistency: Guarantees uniformity even in high-volume production.

As well as the flexibility to run one off pieces.

3. Material Compatibility:

Challenge:

Diverse materials require tailored approaches for consistency.

Solution: Versatile machines handle various materials, ensuring adaptability and consistent finishing.

additional insights

Material-Specific Challenges: The MAX addresses material-specific intricacies.

Transitioning Between Materials: Seamless adaptation minimizes downtime during material shifts.

4. Complex Geometries:

Challenge

Achieving uniform finishing in intricate geometries is challenging.

Solution: Advanced machines with multi-axis capabilities navigate complex shapes with precision.

additional insights

Features: The MAX’s 11-AXIS accesses intricate internal spaces efficiently unlike anything on the market.

Variable Thickness Challenges: Precision extends to variable thicknesses, overcoming challenges associated with varying thicknesses within a single part.

No Masking: Our patented Focused Deburring saves time with precision, never mask another part.

5. Efficiency and Speed:

Challenge

Meeting tight deadlines while maintaining high precision is a common struggle.

Solution: High-speed deburring machines with multi-axis control significantly reduce processing times without compromising quality.

additional insights

Rapid Job Setup: The MAX streamlines job setup processes for increased efficiency, by employing quick set up and part change out.

Adaptability to Production Changes: Flexibility allows quick adjustments to production changes. Chamfer, polish or deburr a one-off part or 1000’s of the same part. Adaptability allows various size manufactures to employ automation.

Conclusion:

In the complex landscape of part finishing, mastering precision requires overcoming various challenges. Advanced deburring and chamfering machines, exemplified by The MAX, offer practical solutions to elevate your manufacturing process. By integrating these technologies, you can navigate the intricacies of part finishing with confidence, achieving not only precision but also efficiency and sustainability. Explore the transformative potential of advanced machinery and stay ahead in the pursuit of mastering precision in manufacturing.

Contact us for more information on 11-axis machining. Sales@James-Engineering.com

Engineering Every Day

Design engineer Zack Lindsey gives us the inside scoop about his time at James Engineering and all he accomplished before it.

Between designing new parts on SolidWorks and working on his car, Zack Lindsey keeps busy. While Lindsey grew up besides the Rocky Mountains as a Colorado native, he was taking apart and rebuilding anything he could get his hands on; he was destined to be an engineer before he even knew it. Eventually, Lindsey graduated from CU Boulder with a bachelor’s degree in mechanical engineering with a minor in economics. Completing a bachelor’s program is no small feat, and Lindsey reflects on his toughest class: “The capstone senior project was definitely the most immersive class [I took]. It’s really like a mini engineering job; that’s how I’d describe it. You’re doing all the steps in the engineering process—you’re designing, making sure your customer is happy, purchasing parts, testing everything, manufacturing everything. It was really comprehensive.” Lindsey later confirms that whilst this was the most challenging class he took, it was also the one that prepared him the most for his career outside of school.

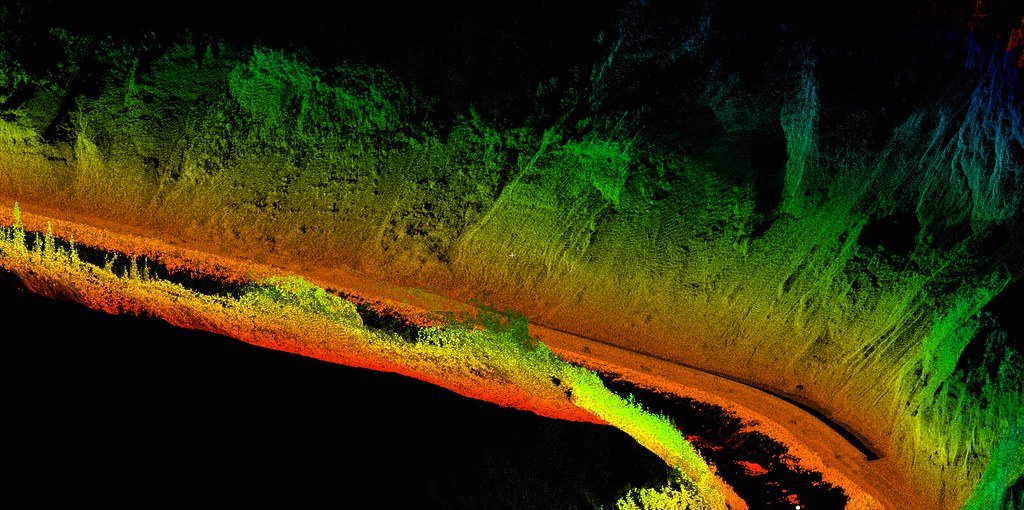

Example of LiDAR imaging

“[My team] worked with NOAA (National Oceanic and Atmospheric Association), and we designed a LiDAR scanner. Essentially, it was a big gimble mount that had a LiDAR laser underneath, and they wanted to be able to point it in any direction in the sky within a whole dome without it ever being limited.” LiDAR is an acronym for “light detection and ranging” and is a method of laser sensing used by scientists and meteorologists to study different environments, both natural and manmade. “The LiDAR beam detects particulates in the atmosphere, and it allows us to get data on how much particulate is in atmosphere, [as well as] its direction and speed. So it’s really helpful for high level and low level wind maps, making predictions, and finding the highs and lows in a [specific] area.” LiDAR isn’t only used for weather-predicting purposes, however—it can also be found in everyday items, such as phones and cars. Apple began utilizing it in 2020, and now the entirety of the iPhone series uses it to enable Face ID and enhance camera quality. Car brands such as Nissan, Subaru, Mercedes, and Volvo have also implemented LiDAR technology, which allows cars to sense any objects around them to prevent unnecessary collisions.

After taking a couple months off to recoup from his breakneck studies, Lindsey found a place to land at James Engineering as our design engineer. When asked to describe what a typical day looks like for him here, he laughs and says, “There isn’t really such a thing as an average day. Some days I’m here [at my desk] designing new parts, some days I’m just doing drawings. Other days I need to fix a problem on a machine, so I’ll design something, make the part, go out into the shop, install it, test it, make sure it’s what I want, and make revisions on the computer [if need be].” A tedious process, but one that’s essential for business. Without the engineering team’s relentless drawing, testing, and redrawing, assemblies would fall apart after the first build. “I also organize lists for different machines to figure out what parts they need manufactured, purchased, powder coated, anodized, things like that.” There are a lot of moving parts within James Engineering, and Lindsey’s organization is key to maintaining a smooth operation.

With as many responsibilities as Lindsey carries, he faced a steep learning curve when he first stepped into his position at James Engineering, but he ultimately defeated it with determination. “There’s definitely a lot of tasks I didn’t know how to do beforehand and I kind of just had to learn how to do it on the fly. It has been challenging but it’s been really helpful in the long run.” Here at James Engineering, we encourage asking questions and hands-on experience. Senior engineers are readily available to teach valuable lessons that can be applied in and out of the workplace, and it was these mentors that helped Lindsey find his footing. We urge our engineers to get their hands dirty and help out in the machine shop when they can, as well as execute their own innovative ideas. Afterall, engineering is inherently centered around creativity and problem solving. So as a creator himself, Lindsey finds great satisfaction in perfecting his projects, especially when they are done “on the fly”. He talks on his most rewarding moments at James Engineering: “Every time a machine goes out that door which I’ve done a lot of the design work on it’s really fulfilling, seeing it on the truck and leaving.” Lindsey offers some advice to people who are just getting started as engineers, saying, “The best way to design is to just do it and see if it works. You’re never going to get it right the first time, so you learn from your mistakes. Another piece of advice I’d give is design in a failure point or else the system is going to design it in for you!”

Outside of his time at James Engineering, Lindsey enjoys spending his time working on his car. “I’m a big car guy, so I like to make parts and sell them.” Even when out of the office, Lindsey is developing his skills as an engineer. “I’d love to develop my own racecar parts one day, but I’m not quite there yet.” In the meantime, you can find Lindsey working diligently on different tasks throughout the shop. “The thing that’s helped me the most is learning to work with a manual machine because I’ve really learned what the capabilities of the shop are. [It’s] learning how to make a part in a way that will make it easier for the machinists.”

It's thanks to motivated employees like Zack Lindsey that James Engineering and other manufacturers alike can thrive. Whether they know they want to be an engineer from the start, or discover it years down the line, their knowledge, expertise, and efforts strengthen the engineering world one part at a time.

Part Finishing 101: A Beginner's Guide

Part finishing is an in-depth process requiring multiple different applications to ensure parts are processed to perfection.

Every piece of machinery is made up of a thousand smaller pieces all continuously working together to accomplish the same goal. Every single one of these pieces need to go through the part finishing process, which ensures they work correctly and keep the overall operation running smoothly. “Part finishing” is an umbrella term for all the individual processes and techniques that go into the ultimate completion of these parts/gears.

Machining

First, let’s start with machining. This is where gears/parts are initially manufactured out of blocks of raw material. CNC (computer numerical control) machines do most of this work, and there are multiple different kinds of CNC machines, such as milling machines, lathes and turning machines, laser cutting machines, etc. Excess material is carved away by these machines to reveal the rough shape of whatever gear/prismatic part is being created. Once this first step is completed, the nitty-gritty side of part finishing begins.

Deburring

Deburring is the process of removing burrs from the edges and surfaces of these freshly cut parts/gears. Burrs are sharp bits of excess metal that will eventually ruin the integrity and overall quality of whatever part/gear they’re stuck to. This process can be done by hand, in a CNC machine, or a machine made specifically for deburring*, such as a James Engineering machine. Deburring is one of the most crucial aspects of part finishing, as many other processes cannot be done if a part or gear is not deburred properly.

Surface Grinding

This process creates smooth surface finishes on metal and non-metal parts alike. It’s an abrasive process which uses grinding wheels to shave down any surface impurities that might affect the functionality and aesthetic of a gear/part. Grinding wheels (add link to website page here) come in a variety of sizes and materials, which directly determine a wheel’s grinding intensity. Grinding surfaces are crucial when it comes to achieving tight part tolerances, as it ensures a part will fit perfectly within its environment. Surface grinding will also rid a part/gear of any corrosive layers that may negatively affect its overall durability.

Polishing

Polishing is done to further smoothen a part’s surface. What makes polishing different from surface grinding is that it’s meant to enhance surface quality, whereas grinding is used to remove extra material. Polishing is also an abrasive process, and it uses polishing pastes and abrasive pads. Polished parts are reflective and more resistant to corrosion, which makes it a crucial step in the finishing process for items such as car bumpers, medical equipment, mirrors, and more.

Buffing

Many people get buffing and polishing confused—but it’s fair considering how alike these two processes are. What makes them different is their levels of aggression. Buffing is the more aggressive of the two, and can actually remove surface material if done too hard. It can be used to remove shallow scratches, and unlike polishing, it will not leave a highly reflective surface. Buffing is frequently used in the automotive, jewelry, and electronic industries.

Chamfering

This step of the part finishing process is extremely important, especially for pieces with right-angled edges. Chamfering is when these edges are cut at a slope, which later makes assembly easier and reduces the amount of stress risers within a gear/part. Sharp, non-chamfered edges can snap and break off, leading to loose material floating throughout a machine. This debris could ultimately affect the efficiency of the entire machine, and even cause it to fail completely. When edges are chamfered, the likelihood of such an occurrence is reduced drastically. It will also ensure that pieces fit together more snugly, reducing the risk of the parts themselves becoming too loose.

Brushing

Brushing can be categorized as a type of deburring, as it can technically get rid of excess burrs left on the surfaces of parts. But that’s not its man job—brushing is used as a way to further perfect part surfaces, as it preps parts for coatings and rids them of any external contaminants, such as oils, dirt, residue, etc. It is also a very precise process in the sense that if only one small section of a part/gear needs further surfacing, a brush can stay focused on that specific spot without affecting the rest of the gear/part’s body. An important thing to remember when it comes to metal brushing is that certain brushes must be used on certain metals; for example, stainless steel can only be brushed with steel brushes. But other materials, such as rubber and leather, can also be brushed if need be.

Sandblasting

This process is also known as abrasive blasting, as it can be done with many other substances other than sand, such as glass beads, water, dry ice, and compressed air. This is another technique used to smoothen, decontaminate, and shape surfaces. This technique of part finishing comes from the naturally occurring phenomenon called aeolian erosion, which is when an environment’s geography is changed and shaped by consistent winds. Blasting is done manually when a blasting substance is mixed with air in a pressurized chamber and dispensed through an abrasive-proof handheld nozzle.

Washing

The washing process works exactly how you’d think it would—a mixture of hot water, solvent, or washing fluid are dispensed either by hand or by a machine over freshly-processed parts to clean them of excess swarf. It’s important to wash parts of debris because, as mentioned above, debris can drastically decrease the effectiveness of a part/gear and the greater machine it was assembled into. In order to avoid corrosion or rusting, special fluids must be used to protect both the part being washed and the machine doing said washing.

Overall

Machining, deburring, chamfering, washing, brushing, surface grinding, polishing, buffing, and sandblasting are the most common part finishing processes in the manufacturing industry, but there are still a variety of methods used that were not mentioned. Each process has its own unique use, and it’s crucial that manufacturers understand what method will produce the strongest outcome for a part or gear.

How James Engineering Part Finishes

Here at James Engineering, we are experts when it comes to the varying methods of part finishing. We manufacture and sell all all-encompassing surface finishing and chamfering machine known as the MAX System, and it’s got you covered completely—the MAX can deburr, chamfer, wash, brush, and even radius parts/gears of various sizes. The best part is the MAX can carry out multiple processes at once, which exponentially cuts down on processing time and leads to a higher production volume.

If you’d like to experience the effortless efficiency of a multitasking finishing fiend, contact us at Sales@James-Engineering.com and we will send you a quote!

*For being such a vital part in the finishing process, deburring machines are an extremely niche market of their own. James Engineering specializes in deburring and chamfering machines and offers a variety of systems at competitive pricing. Click here to learn more about the different kind of systems we manufacture.