CASE STUDY: Manufacturing Customer Survey Finds The Following Results

In 2011, we conducted a client survey of over 1500 manufacturers, across varied industries doing manual and hand deburring.

How Much Production Time Are You Losing?

Set up? Processing Time? The MAX speeds all of this!

FASTEST CHANGE OUTS:

This doesn’t even include the faster processing time of each part... If you deburr 250 parts a month, you could save approximately 120 hours in setup time alone.

How much production time are you losing?

Set up? Processing Time? The MAX speeds all of this!

Once a setup is made, it is saved as a recipe.

Recipes are called up by filename instantly.

No Changeover or setups!

*As an option, we also offer auto-part ID.

Lower your Cost Per Part!

The MAX Systems are ideal for applications where parts are run on a repeat basis. The frequency and

volume is not important. In other words, you can run a different part every single cycle as long as

the parts are re-run at some point; even if it is five years down the road. Your saving yourself time and money!

Fastest Cycle Times in the Biz!

Run a different part every cycle!

Automatic Wheel Wear Compensation

Chamfer, Radius or any other type of edge finish

It has been about five years since we bought your deburring machine. I can boast that we have greatly improved the quality of gears as opposed to hand deburring. The productivity is unmatched! Many of the parts used to take 30 minutes by hand and now the same part is done in about 30 sec.

— Ramdas Amin, Mfg Engineer, GE Aviation Systems

I have been using a James Engineering 462 for about 4 years now. It works wonderful I can’t imagine working without that machine. It has done our company justice!

— Tim Fuller, Manufacturing Engineer, Baldor

We have benefited from faster set-up times to faster cycle times. The machine has functioned effectively without failure ever since we powered it up in 2005.

It is extremely easy to set up on spiral bevel ring gears and many other parts we manufacture.

We highly recommend it for any company interested in improving their deburring processes

— Paul Campion, GM, Reliance Gear

See more of our customers here.

Mastering Precision: A Comprehensive Guide to Overcoming Part Finishing Challenges

In the intricate realm of manufacturing, achieving precision in part finishing is an ongoing pursuit that directly influences the quality and functionality of the final product. This comprehensive guide explores the common challenges encountered in part finishing and offers valuable insights into overcoming these hurdles with the help of advanced deburring and chamfering machines.

In the intricate realm of manufacturing, achieving precision in part finishing is an ongoing pursuit that directly influences the quality and functionality of the final product. This comprehensive guide explores the common challenges encountered in part finishing and offers valuable insights into overcoming these hurdles with the help of advanced deburring and chamfering machines. Let's embark on a journey to master precision in part finishing.

1. Unwanted Burrs and Sharp Edges

Challenge:

Unwanted burrs and sharp edges can compromise functionality and aesthetics.

Solution: Unwanted burrs and sharp edges can be effectively removed through various methods. Manual tools like files, abrasive brushes, and rotary deburring tools offer precision, while techniques such as abrasive blasting, chemical deburring, and thermal methods provide automated solutions. Advanced approaches like electrochemical deburring, cryogenic methods, waterjet cutting, and laser deburring cater to specific needs, emphasizing the importance of selecting the most suitable method based on material, part complexity, and production requirements.

Additional Insights:

2. Inconsistent Surface Finish:

Challenge:

Achieving a consistent surface finish is crucial for quality standards.

Solution: Achieving a consistent surface finish is crucial for quality standards because it directly impacts the appearance, functionality, and performance of a finished product. Consistency ensures uniformity in texture and appearance, which is especially important in industries where aesthetics matter, such as automotive, aerospace, or consumer electronics. Additionally, a consistent surface finish is indicative of precision and attention to detail in manufacturing processes, reflecting a higher level of quality and meeting the stringent standards expected by customers and industry regulations. In applications where friction, wear, or corrosion resistance are critical factors, a uniform surface finish is essential for optimal performance and longevity of the final product. Overall, consistency in surface finish contributes to the reliability, durability, and overall quality of the manufactured components or products.

Additional Insights:

Multi-axis deburring and chamfering machines, like the 11-Axis MAX provide control for a uniform finish, meeting specifications.

Large Batch Consistency: Guarantees uniformity even in high-volume production.

As well as the flexibility to run one off pieces.

3. Material Compatibility:

Challenge:

Diverse materials require tailored approaches for consistency.

Solution: Versatile machines handle various materials, ensuring adaptability and consistent finishing.

additional insights

Material-Specific Challenges: The MAX addresses material-specific intricacies.

Transitioning Between Materials: Seamless adaptation minimizes downtime during material shifts.

4. Complex Geometries:

Challenge

Achieving uniform finishing in intricate geometries is challenging.

Solution: Advanced machines with multi-axis capabilities navigate complex shapes with precision.

additional insights

Features: The MAX’s 11-AXIS accesses intricate internal spaces efficiently unlike anything on the market.

Variable Thickness Challenges: Precision extends to variable thicknesses, overcoming challenges associated with varying thicknesses within a single part.

No Masking: Our patented Focused Deburring saves time with precision, never mask another part.

5. Efficiency and Speed:

Challenge

Meeting tight deadlines while maintaining high precision is a common struggle.

Solution: High-speed deburring machines with multi-axis control significantly reduce processing times without compromising quality.

additional insights

Rapid Job Setup: The MAX streamlines job setup processes for increased efficiency, by employing quick set up and part change out.

Adaptability to Production Changes: Flexibility allows quick adjustments to production changes. Chamfer, polish or deburr a one-off part or 1000’s of the same part. Adaptability allows various size manufactures to employ automation.

Conclusion:

In the complex landscape of part finishing, mastering precision requires overcoming various challenges. Advanced deburring and chamfering machines, exemplified by The MAX, offer practical solutions to elevate your manufacturing process. By integrating these technologies, you can navigate the intricacies of part finishing with confidence, achieving not only precision but also efficiency and sustainability. Explore the transformative potential of advanced machinery and stay ahead in the pursuit of mastering precision in manufacturing.

Contact us for more information on 11-axis machining. Sales@James-Engineering.com

The Machine Shop at James Engineering

Get an inside scoop about the machine shop at James Engineering from a Q&A with lead engineer, Dave Schlosser, and company vice president, Scott Richards.

The Colorado-based OEM shop is known for their one-of-a-kind deburring and chamfering machines, but they also have a precision-focused machine shop that’s willing to take on any project that comes their way. If you’re in the market for a low to medium volume machine shop who guarantees quality products, reach out to James Engineering today at (303) 444-6787.

—

What is our shop capable of?

Dave: We have 3 mills and 2 lathes. One of the mills has 4th axis capability. We’re capable of holding concentricity within 5/10ths in most cases without have to do any crazy set ups. We can do round parts, square parts, just about any shape part that you want.

Scott: We’ve got a live tool lathe with a bar feed option and multiple seats of programming software. We’ve got that 4th axis mill, another smaller mill with a 20-inch bed, and we’ve got a 60-inch bed large mill.

How many parts a week do we typically make?

Dave: That’s pretty subjective because we do short run production, so most of our time isn’t spent making parts, it’s getting ready to make a part and getting a part set up to run. Typically, we could spend half hour programming, half our setting up, and basically we could run for 15 minutes and then be done (in some cases). We can’t really quantify the quantity of parts per week because we’re more set up to be a tooling or prototype shop versus a production shop.

Can customers send in their own designs?

Dave: We quote on stuff and have stuff made for outside companies. We have engineering services, so people can send in a concept and we could do the whole thing, or they could send in a thing that’s basically done and we could create drawings for them, things like that. We have start-to-finish capability, or we can pick up a project that they’re already halfway through. We can also provide good drawings, give them a model.

What are some basic jobs we do frequently?

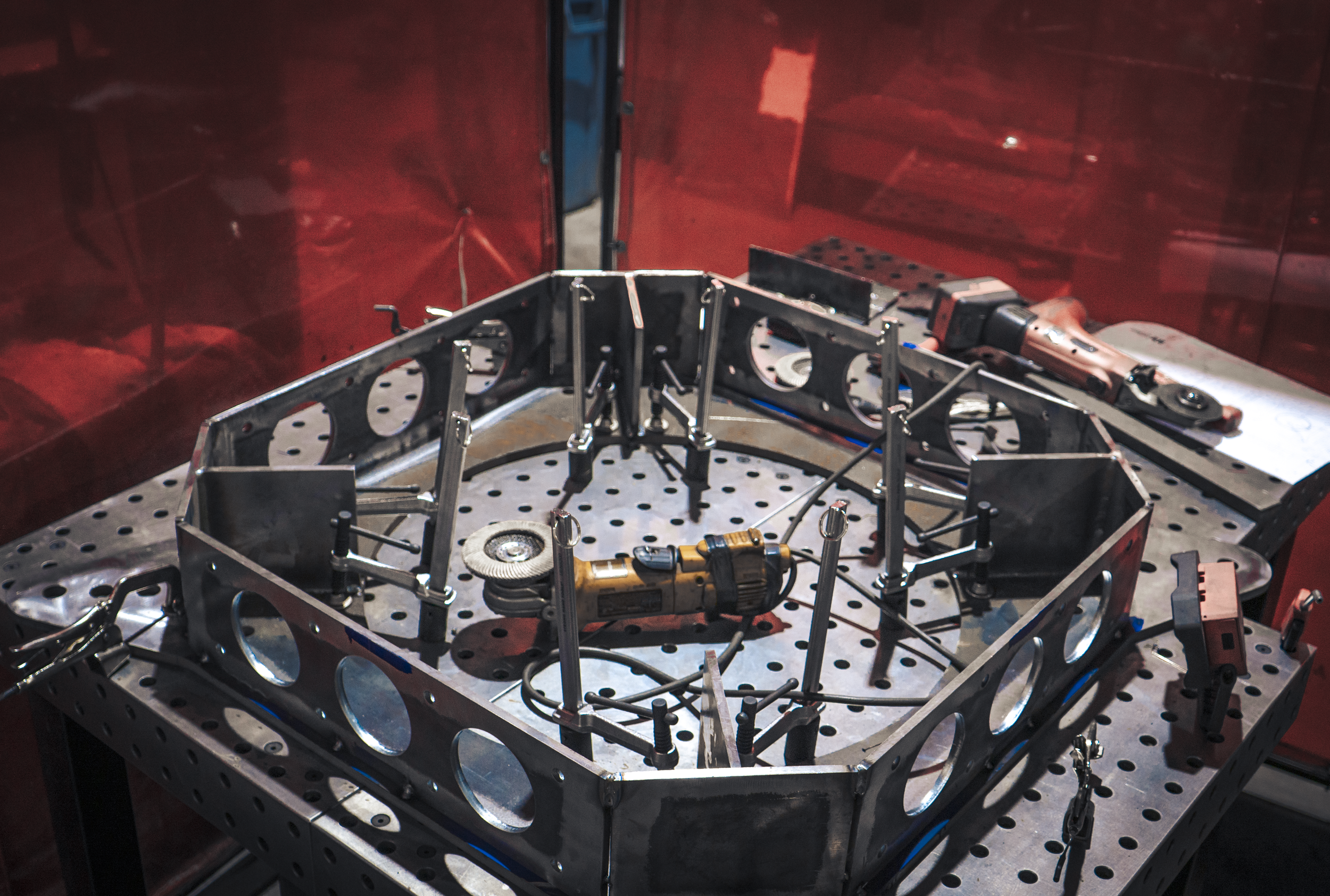

Dave: We do a lot of gun parts, automotive stuff, motorcycle parts. It really is just a gamble. Basically, anybody who walks into the door with a project, we can take a look at it and see if it fits our capabilities fairly easy and we’ll do it. We’ve done a lot of welding jobs lately, too. We’ve done a lot of stuff for RoboCon; we’ve made a lot of platforms and fixturing. We’ve made brownie bowls, and stuff for volleyball companies, it doesn’t really matter what industry comes in.

Scott: So we’ve got a lot of high end, high precision parts that we make. For example, we’re making a mount for a vehicle right now. Our perfect job is a volume job. We’re really looking for anything from prototype to a few thousand parts a week. I wouldn’t call ourselves high volume where we’re tens of thousands of parts per week, but we’re definitely looking for that low to medium volume area.

What makes our shop stand out?

Dave: Our attention to detail and the quality of our parts. That’s something that we take a lot of pride in. We try to go that one step above, whether it’s by deburring or not putting a scratch on it by pushing it across surfaces, things like that. We take really good care of all the parts we make, and it’s a lot easier to go in and get the quality you’re looking for when you’re not making thousands and thousands of parts.

Why is it significant for our machine side of business that we make our own parts in-house?

Dave: We can control our own quality because our standards are really high. To be able to get the tolerances and stuff we need we can hardly get other people to make them for us. We put a dimension on a drawing and expect you to hold it, so in some cases we put really tight tolerances on things with reason, and when other companies see those tight tolerances the cost goes up automatically (whether it’s justifiable or not). It’s more cost efficient for us to do it.

Scott: We have to make all of these parts here in-house because we really can’t afford to job much of this out. We’ve got to keep our profit margins where they need to be. We have to hold pretty precision fits because we’ve got a 3.2 million resolution encoder here turning all of these [parts] on this five-axis manipulator.

How do your own deburring machines fit into the machine shop process?

Scott: When we make these parts, we do a lot of in-machine deburring. We’ll go through and we’ll machine this edge with a chamfer tool. But the problem is, when we machine the edge with the chamfer tool, the chamfer tool creates two sharp edges. We still have this problem where a technician has to go in with Scotch-Brite and deburr this. So we don’t want that abrasive to get into our CNC machine, because if that abrasive gets into our machines, it gets down into ways and slides and it wears the machine out. That’s where the market is for our deburring machine.