Machine Finishing Made Simple | Push-of-a-Button Deburring and Chamfering

A Deburring machine for sale like no other. Our machines have helped streamline manufacturers' processes for 40 years. Big or small, the answer for how to deburr machined parts is here.

A Deburring machine for sale like no other. Our machines have helped streamline manufacturers' processes for 40 years. Big or small, the answer for how to deburr machined parts is here.

From deburring to chamfering, polishing to washing, and everything in between, our machines have got you covered. Whether you're dealing with gears or non-gears, micron-sized parts or massive components over 25 feet and 1000+ pounds, our systems are built tough to handle it all.

Choose from manual, semi-automatic, or fully automated options to suit your needs. Upgrading your finishing process has never been easier!

What is Gear Hobbing?

Understanding Gear Hobbing and Deburring in Manufacturing. What is Gear Hobbing? Gear hobbing is a machining process used to cut gears, splines, and sprockets. What is the Difference Between Gear Cutting and Hobbing? Why is it Important to Remove Burrs? What is the Effect of Deburring?

We answer ALL your questions!

Understanding Gear Hobbing and Deburring in Manufacturing

In manufacturing, precision and efficiency reign supreme. At the heart of achieving these goals are understanding two pivotal processes: gear hobbing and deburring. This article will explore what gear hobbing is, distinguish it from gear cutting, and delve into the importance of removing burrs and the effects of deburring.

What is Gear Hobbing?

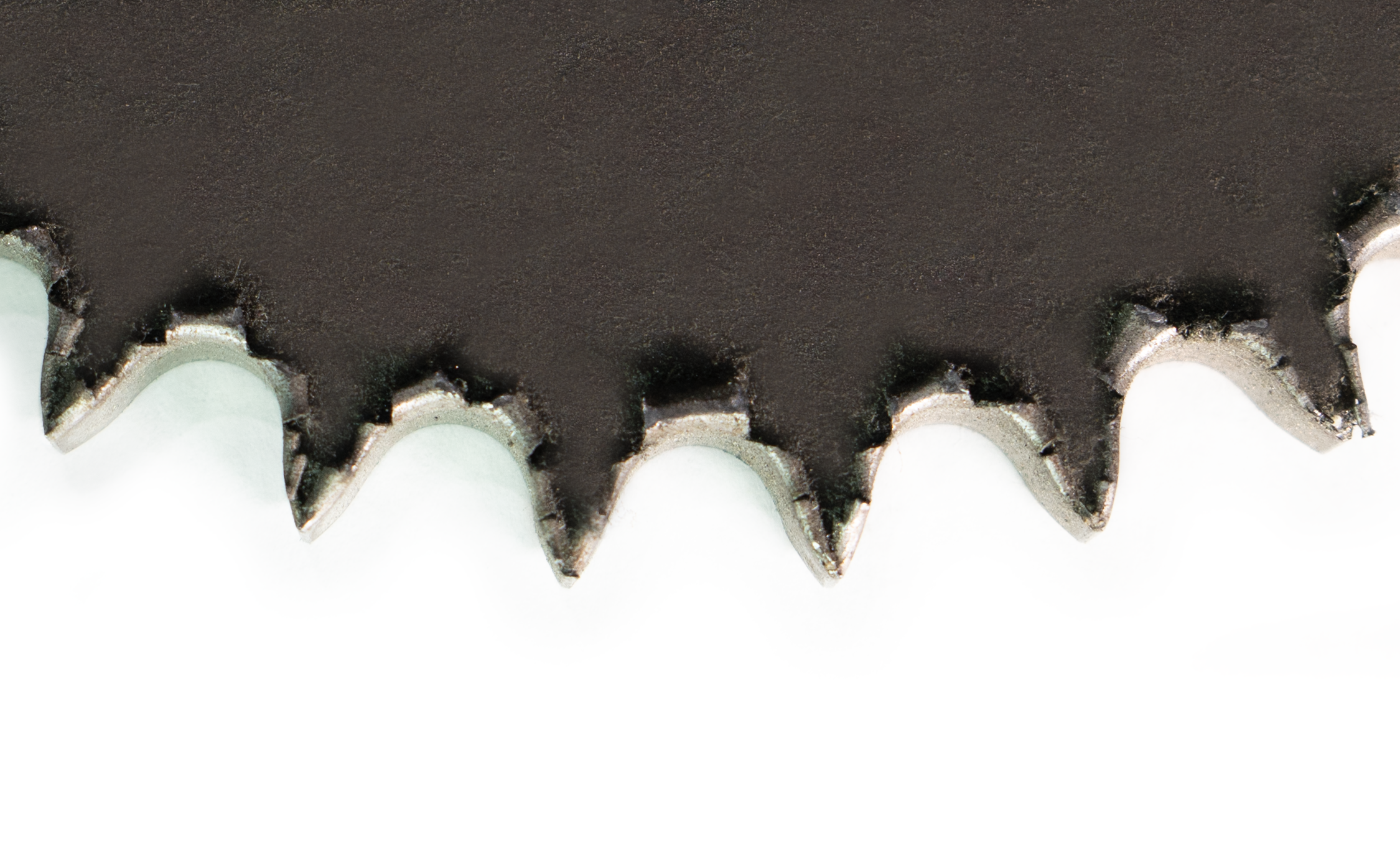

Gear hobbing is a machining process used to cut gears, splines, and sprockets. It involves using a specialized cutting tool known as a hob, which rotates continuously while being fed into the workpiece to progressively carve out the gear teeth. This process is highly efficient and can produce a wide range of gear sizes and shapes with high precision. Gear hobbing is commonly used in the automotive, aerospace, and machinery industries due to its ability to produce high-quality gears at a relatively low cost.

What is the Difference Between Gear Cutting and Hobbing?

While gear hobbing is a type of gear cutting, not all gear cutting processes are hobbing. Gear cutting is a broad term that encompasses various methods used to create gear teeth, including hobbing, shaping, milling, and broaching.

Gear Hobbing: Utilizes a hob and is suitable for producing both spur and helical gears. It is known for its efficiency and versatility in creating various gear profiles.

Gear Shaping: Uses a reciprocating cutter to cut the gear teeth. It is particularly useful for internal gears and gears with complex shapes.

Gear Milling: Involves using a milling machine and a form cutter to create the gear teeth. This method is typically used for small production runs or prototype gears.

Gear Broaching: Uses a toothed tool called a broach to cut the entire gear profile in a single pass. It is ideal for producing large quantities of gears quickly.

Each of these methods has its advantages and specific applications, but gear hobbing is often favored for its combination of speed, precision, and versatility.

Why is it Important to Remove Burrs?

Burrs are unwanted, rough edges or protrusions that remain on metal parts after machining processes such as cutting, drilling, or grinding. These burrs can have several detrimental effects if not removed:

Safety Hazards: Burrs can cause injuries to workers handling the parts.

Assembly Issues: Burrs can interfere with the proper fitting and functioning of parts in assemblies.

Performance Problems: Burrs can affect the performance and longevity of mechanical components, leading to increased wear and tear or even failure.

Aesthetic Concerns: Burrs can negatively impact the appearance of the final product.

Why is Deburring Necessary?

Deburring is the process of removing burrs from metal parts. It is a crucial step in the manufacturing process for several reasons:

Enhances Safety: By removing sharp edges, deburring prevents potential injuries to workers and end-users.

Improves Functionality: Deburred parts fit together more precisely, ensuring proper assembly and optimal performance of mechanical systems.

Extends Product Life: Deburring reduces friction and wear, which can extend the lifespan of components.

Ensures Quality: Removing burrs improves the overall quality and appearance of the product, making it more attractive to customers and less likely to be returned due to defects.

What is the Effect of Deburring?

The effects of deburring extend beyond mere aesthetics and safety. Deburring can significantly impact the overall quality and performance of manufactured parts. Here are some key effects:

Enhanced Durability: By eliminating stress concentrations that can lead to cracks or failures, deburring contributes to the structural integrity of components.

Improved Precision: Deburred parts have cleaner edges and more accurate dimensions, which is critical for applications requiring high precision.

Better Surface Finish: The removal of burrs results in a smoother surface finish, which can improve the part's functionality and reduce the risk of corrosion.

Increased Efficiency: Parts that fit together properly reduce the likelihood of mechanical failures and downtime, leading to more efficient operation of machinery and equipment.

In conclusion, gear hobbing and deburring are essential processes in the manufacturing industry. Gear hobbing allows for the efficient and precise production of gears, while deburring ensures the safety, functionality, and quality of the final products. Understanding these processes and their significance helps manufacturers produce high-quality components that meet the rigorous demands of various industries.

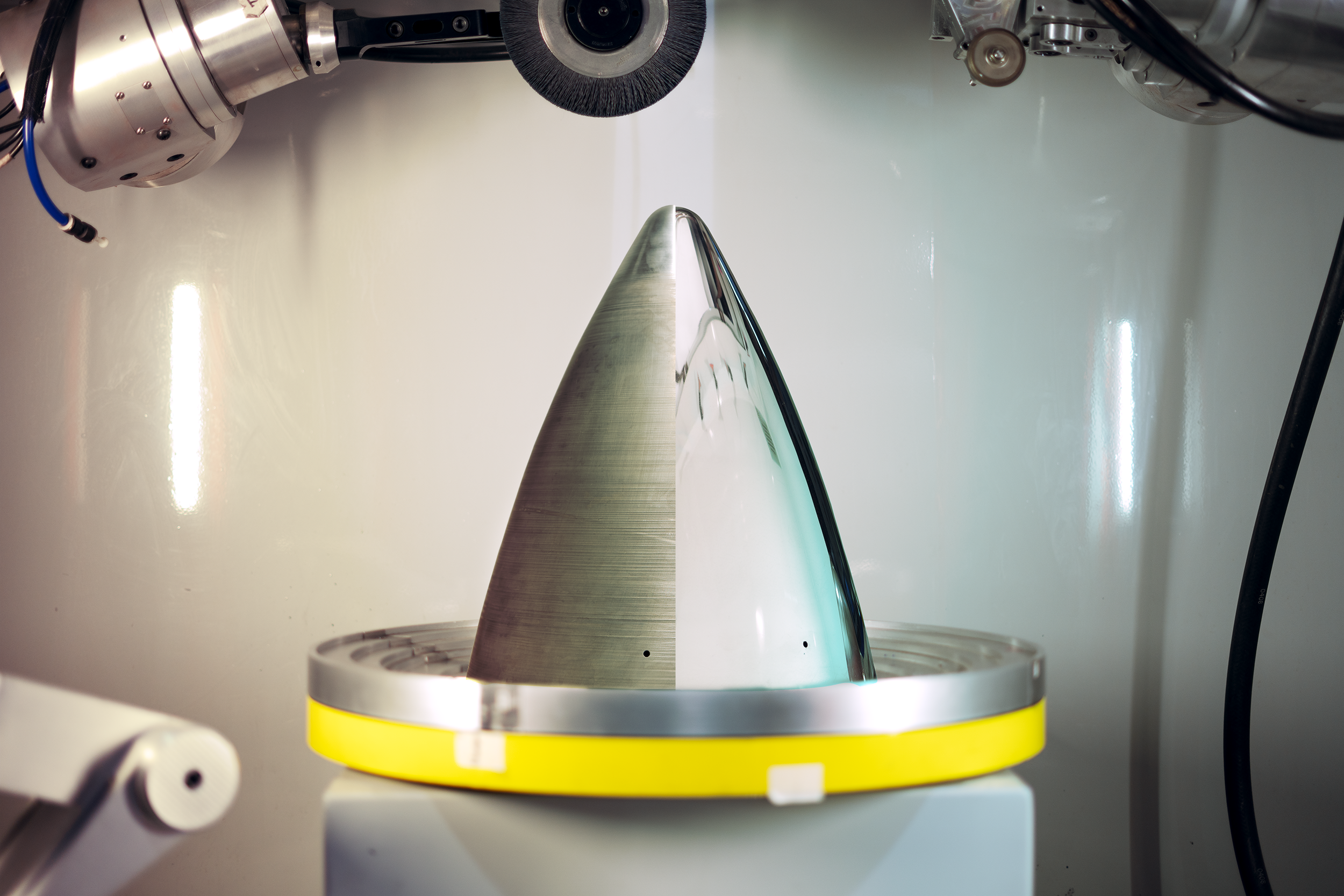

Deburring and Part Finishing in the Aerospace Sector: Exceeding Industry Standards

In the dynamic world of aerospace engineering, precision and quality are paramount. Every component, no matter how small, plays a crucial role in the overall performance and safety of an aircraft. One often overlooked but essential process in aerospace manufacturing is deburring and part finishing. This article explores the significance of deburring, its role in meeting industry standards, and the latest techniques employed by top engineers in the aerospace sector.

In the dynamic world of aerospace engineering, precision and quality are paramount. Every component, no matter how small, plays a crucial role in the overall performance and safety of an aircraft. One often overlooked but essential process in aerospace manufacturing is deburring and part finishing. This article explores the significance of deburring, its role in meeting industry standards, and the latest techniques employed by top engineers in the aerospace sector.

Apache Longbow manufactured by Boeing

Understanding Deburring:

Deburring is the process of removing unwanted rough edges, burrs, or imperfections from machined or manufactured parts. In aerospace, where precision is non-negotiable, deburring ensures that components fit seamlessly together, reducing the risk of mechanical failure and enhancing overall efficiency.

Importance in Aerospace Manufacturing:

Aerospace components undergo intricate machining processes, leaving behind sharp edges and burrs. These imperfections can compromise the structural integrity of the parts and, consequently, the entire aircraft. Deburring is not merely a cosmetic enhancement; it is a critical step in maintaining the safety and reliability of aerospace systems.

Industry Standards:

The aerospace industry adheres to rigorous standards and regulations to ensure the highest level of safety and performance. Deburring plays a pivotal role in meeting these standards, as components must not only meet precise dimensional specifications but also undergo thorough inspection to eliminate any defects that could compromise the integrity of the final product.

an aerospace finish does not allow for any

grinding marks

surface blemishing

surface scratches

any jagged edges

inconsistencies and so on.

since most parts are “life critical”,

THE AEROSPACE INDUSTRY demands perfection.

F-22 Raptor Lockheed Martin/Boeing

Latest Techniques in Aerospace Deburring:

As technology advances, so do the techniques employed in aerospace deburring. Top aerospace and defense producers now utilize state-of-the-art equipment, such as The MAX, an 11-axis multi-finishing system that offers unparalleled accuracy, consistency, and speed in finishing processes. The use of the patented Focused Deburring, ensures that even the most intricate components can be deburred with precision, meeting the stringent requirements of aerospace applications. While also contributing to increased efficiency and cost-effectiveness in the overall manufacturing process.

THE MAX

11-Axis Advanced Multi-Finishing System

Equipped with up to 4 different precision finishing tools has revolutionized the aerospace and defense industry.

In the demanding field of aerospace engineering, every detail matters. Deburring and part finishing are essential steps in ensuring the integrity, safety, and performance of aerospace components. As technology continues to evolve, top manufacturers will continue to embrace innovative solutions to meet and exceed industry standards. The combination of precision, automation, and advanced methods propels aerospace manufacturing into a future where safety and quality are never compromised.

To learn more about The MAX click here.

If you’re interested in learning how to improve your own finishing process, give James Engineering a call at (303) 444-6787, or email us at Sales@James-Engineering.com.

Mastering Precision: A Comprehensive Guide to Overcoming Part Finishing Challenges

In the intricate realm of manufacturing, achieving precision in part finishing is an ongoing pursuit that directly influences the quality and functionality of the final product. This comprehensive guide explores the common challenges encountered in part finishing and offers valuable insights into overcoming these hurdles with the help of advanced deburring and chamfering machines.

In the intricate realm of manufacturing, achieving precision in part finishing is an ongoing pursuit that directly influences the quality and functionality of the final product. This comprehensive guide explores the common challenges encountered in part finishing and offers valuable insights into overcoming these hurdles with the help of advanced deburring and chamfering machines. Let's embark on a journey to master precision in part finishing.

1. Unwanted Burrs and Sharp Edges

Challenge:

Unwanted burrs and sharp edges can compromise functionality and aesthetics.

Solution: Unwanted burrs and sharp edges can be effectively removed through various methods. Manual tools like files, abrasive brushes, and rotary deburring tools offer precision, while techniques such as abrasive blasting, chemical deburring, and thermal methods provide automated solutions. Advanced approaches like electrochemical deburring, cryogenic methods, waterjet cutting, and laser deburring cater to specific needs, emphasizing the importance of selecting the most suitable method based on material, part complexity, and production requirements.

Additional Insights:

2. Inconsistent Surface Finish:

Challenge:

Achieving a consistent surface finish is crucial for quality standards.

Solution: Achieving a consistent surface finish is crucial for quality standards because it directly impacts the appearance, functionality, and performance of a finished product. Consistency ensures uniformity in texture and appearance, which is especially important in industries where aesthetics matter, such as automotive, aerospace, or consumer electronics. Additionally, a consistent surface finish is indicative of precision and attention to detail in manufacturing processes, reflecting a higher level of quality and meeting the stringent standards expected by customers and industry regulations. In applications where friction, wear, or corrosion resistance are critical factors, a uniform surface finish is essential for optimal performance and longevity of the final product. Overall, consistency in surface finish contributes to the reliability, durability, and overall quality of the manufactured components or products.

Additional Insights:

Multi-axis deburring and chamfering machines, like the 11-Axis MAX provide control for a uniform finish, meeting specifications.

Large Batch Consistency: Guarantees uniformity even in high-volume production.

As well as the flexibility to run one off pieces.

3. Material Compatibility:

Challenge:

Diverse materials require tailored approaches for consistency.

Solution: Versatile machines handle various materials, ensuring adaptability and consistent finishing.

additional insights

Material-Specific Challenges: The MAX addresses material-specific intricacies.

Transitioning Between Materials: Seamless adaptation minimizes downtime during material shifts.

4. Complex Geometries:

Challenge

Achieving uniform finishing in intricate geometries is challenging.

Solution: Advanced machines with multi-axis capabilities navigate complex shapes with precision.

additional insights

Features: The MAX’s 11-AXIS accesses intricate internal spaces efficiently unlike anything on the market.

Variable Thickness Challenges: Precision extends to variable thicknesses, overcoming challenges associated with varying thicknesses within a single part.

No Masking: Our patented Focused Deburring saves time with precision, never mask another part.

5. Efficiency and Speed:

Challenge

Meeting tight deadlines while maintaining high precision is a common struggle.

Solution: High-speed deburring machines with multi-axis control significantly reduce processing times without compromising quality.

additional insights

Rapid Job Setup: The MAX streamlines job setup processes for increased efficiency, by employing quick set up and part change out.

Adaptability to Production Changes: Flexibility allows quick adjustments to production changes. Chamfer, polish or deburr a one-off part or 1000’s of the same part. Adaptability allows various size manufactures to employ automation.

Conclusion:

In the complex landscape of part finishing, mastering precision requires overcoming various challenges. Advanced deburring and chamfering machines, exemplified by The MAX, offer practical solutions to elevate your manufacturing process. By integrating these technologies, you can navigate the intricacies of part finishing with confidence, achieving not only precision but also efficiency and sustainability. Explore the transformative potential of advanced machinery and stay ahead in the pursuit of mastering precision in manufacturing.

Contact us for more information on 11-axis machining. Sales@James-Engineering.com

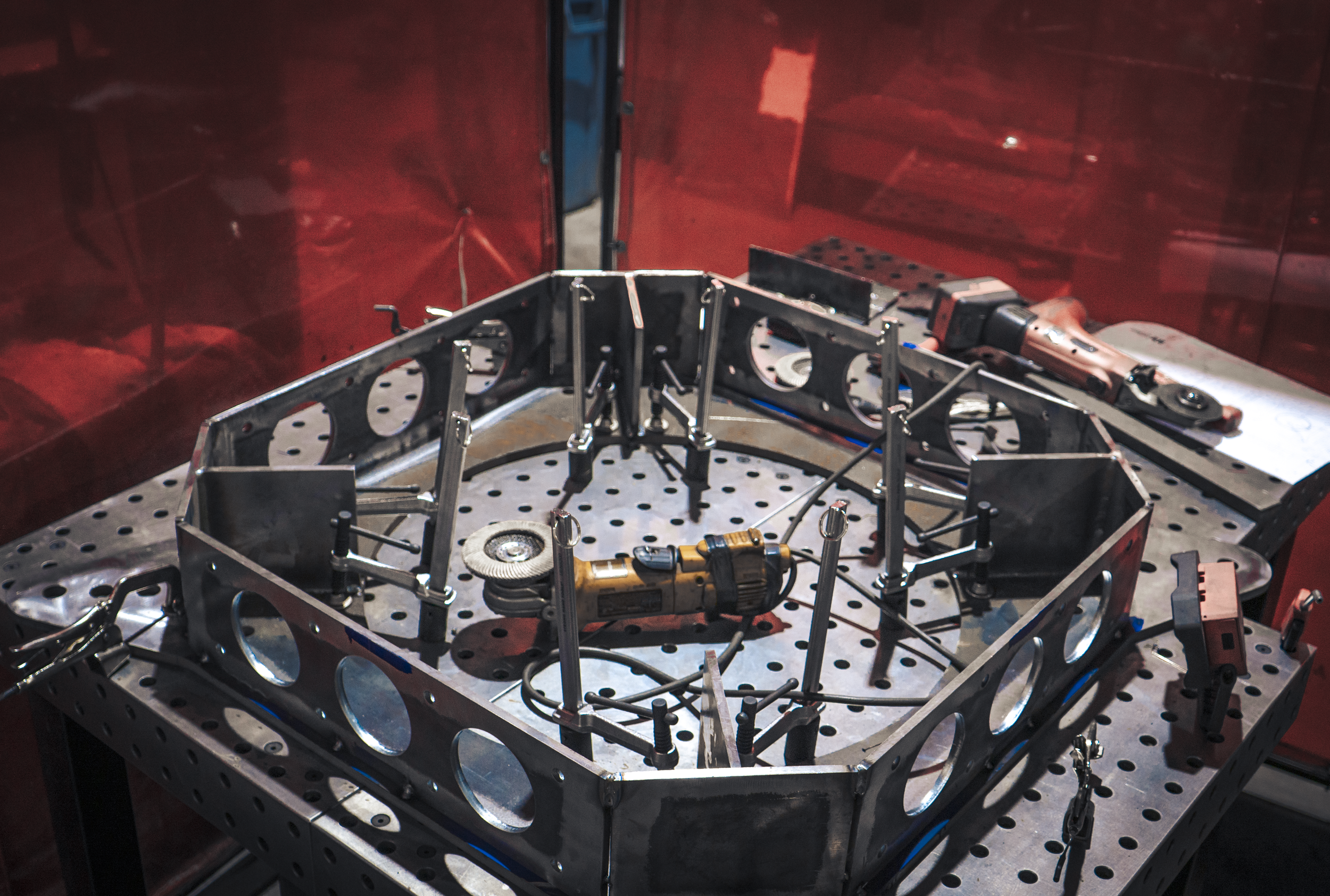

The Machine Shop at James Engineering

Get an inside scoop about the machine shop at James Engineering from a Q&A with lead engineer, Dave Schlosser, and company vice president, Scott Richards.

The Colorado-based OEM shop is known for their one-of-a-kind deburring and chamfering machines, but they also have a precision-focused machine shop that’s willing to take on any project that comes their way. If you’re in the market for a low to medium volume machine shop who guarantees quality products, reach out to James Engineering today at (303) 444-6787.

—

What is our shop capable of?

Dave: We have 3 mills and 2 lathes. One of the mills has 4th axis capability. We’re capable of holding concentricity within 5/10ths in most cases without have to do any crazy set ups. We can do round parts, square parts, just about any shape part that you want.

Scott: We’ve got a live tool lathe with a bar feed option and multiple seats of programming software. We’ve got that 4th axis mill, another smaller mill with a 20-inch bed, and we’ve got a 60-inch bed large mill.

How many parts a week do we typically make?

Dave: That’s pretty subjective because we do short run production, so most of our time isn’t spent making parts, it’s getting ready to make a part and getting a part set up to run. Typically, we could spend half hour programming, half our setting up, and basically we could run for 15 minutes and then be done (in some cases). We can’t really quantify the quantity of parts per week because we’re more set up to be a tooling or prototype shop versus a production shop.

Can customers send in their own designs?

Dave: We quote on stuff and have stuff made for outside companies. We have engineering services, so people can send in a concept and we could do the whole thing, or they could send in a thing that’s basically done and we could create drawings for them, things like that. We have start-to-finish capability, or we can pick up a project that they’re already halfway through. We can also provide good drawings, give them a model.

What are some basic jobs we do frequently?

Dave: We do a lot of gun parts, automotive stuff, motorcycle parts. It really is just a gamble. Basically, anybody who walks into the door with a project, we can take a look at it and see if it fits our capabilities fairly easy and we’ll do it. We’ve done a lot of welding jobs lately, too. We’ve done a lot of stuff for RoboCon; we’ve made a lot of platforms and fixturing. We’ve made brownie bowls, and stuff for volleyball companies, it doesn’t really matter what industry comes in.

Scott: So we’ve got a lot of high end, high precision parts that we make. For example, we’re making a mount for a vehicle right now. Our perfect job is a volume job. We’re really looking for anything from prototype to a few thousand parts a week. I wouldn’t call ourselves high volume where we’re tens of thousands of parts per week, but we’re definitely looking for that low to medium volume area.

What makes our shop stand out?

Dave: Our attention to detail and the quality of our parts. That’s something that we take a lot of pride in. We try to go that one step above, whether it’s by deburring or not putting a scratch on it by pushing it across surfaces, things like that. We take really good care of all the parts we make, and it’s a lot easier to go in and get the quality you’re looking for when you’re not making thousands and thousands of parts.

Why is it significant for our machine side of business that we make our own parts in-house?

Dave: We can control our own quality because our standards are really high. To be able to get the tolerances and stuff we need we can hardly get other people to make them for us. We put a dimension on a drawing and expect you to hold it, so in some cases we put really tight tolerances on things with reason, and when other companies see those tight tolerances the cost goes up automatically (whether it’s justifiable or not). It’s more cost efficient for us to do it.

Scott: We have to make all of these parts here in-house because we really can’t afford to job much of this out. We’ve got to keep our profit margins where they need to be. We have to hold pretty precision fits because we’ve got a 3.2 million resolution encoder here turning all of these [parts] on this five-axis manipulator.

How do your own deburring machines fit into the machine shop process?

Scott: When we make these parts, we do a lot of in-machine deburring. We’ll go through and we’ll machine this edge with a chamfer tool. But the problem is, when we machine the edge with the chamfer tool, the chamfer tool creates two sharp edges. We still have this problem where a technician has to go in with Scotch-Brite and deburr this. So we don’t want that abrasive to get into our CNC machine, because if that abrasive gets into our machines, it gets down into ways and slides and it wears the machine out. That’s where the market is for our deburring machine.

The Difference Between Grinding, Polishing, and Deburring

These three machining processes all seem frustratingly similar—so what makes them different from each other?

Grinding, polishing, and deburring—anybody who knows anything about the precision machining process knows that these three processes are a.) crucial, and b.) acts of surface finishing. These three processes are very similar to each other, and for decades have been making people ask the same questions: What’s the difference? And why do we need to do all three processes? Both of these questions are valid, and we have the answers to both below.

The difference between grinding, polishing, and deburring.

1. Grinding

This is the process of removing material and shaping a workpiece into its final form. Grinding can be done on a multitude of materials, such as plastic, ceramic, and many different metals (stainless steel, titanium, high-nickel alloys, etc.). In order to complete this process, grinding wheels of different abrasives are used in various machines made specifically for grinding. It’s important that the correct kind of abrasive is used, as too soft of an abrasive can’t grind a workpiece enough, while too hard of an abrasive will damage a workpiece and result in decreased part quality or scrapped part. Overall, grinding is essential because it improves a part’s surface finish, which not only provides the aesthetic many industries require, but also ensures the removal of pesky surface imperfections.

2. Polishing

Polishing is the process surface finishing, which is also known as the process of improving surface quality. Using softer, smaller abrasives like polishing compounds and wheels, surface imperfections such as scratches and unwanted film/layers are removed to achieve a part’s desired texture (as different industries require different surface finishes). Polishing can be done by hand, machine, or robot, as it doesn’t require quite as much precision as grinding or deburring do. This step can be taken farther with buffing, which gives parts a finish similar to that of a mirror.

3. Deburring

This process is the act of removing burrs from a part’s surface. Burrs are extra bits of metal that form as a part is being cut, and can be extremely harmful both for a part’s functionality and the overall assembly it’s a part of. Deburring can be done by hand or in a machine, though hand deburring proves to be inconsistent and costly. The process of deburring requires extreme precision, as any leftover bit of metal can cause inconsistencies that result in the decrease of a part’s longevity and efficiency. Deburring is required for any part that has been previously machined and can be done on a variety of different materials, such as ceramic, stainless steel, wood, titanium, and more. What makes it an essential process is it ensures parts meet industry standards and helps reduce the possible formation of stress risers.

Surface Profiling

Seeing as all three of these processes fall under surface finishing, it’s important to know how surface finish is measured. Surface profiling is the measurement of a surface’s roughness, which allows manufacturers to know how adequately prepared a part is for further processing, especially when it comes to the part coating and assembly stages. A profilometer is the tool used to measure these surfaces and can be split into two categories: contact and non-contact. Contact profilometers use a stylus to map out the highs and lows of the surface (also known as peaks and valleys) which allow operators to gauge how smooth or rough a workpiece surface truly is. A non-contact profilometer uses image sensors to detect a surface’s texture. While this is the faster of the two profilometers, it’s extremely sensitive to any dirt or oil that may be coating a part’s surface.

Why does manufacturing require all three processes?

Ultimately, grinding, polishing, and deburring are all needed for the same reasons: dimensional accuracy, part efficiency, corrosion resistance, and improved functionality. All of these processes refine parts so they’re safe, functional, and meet industry standards. In other words, it’s the manufacturing equivalent of editing a piece of writing before publishing. A part might work fine enough after it’s just been cut, but without grinding, polishing, and deburring, it probably won’t fit into its assembly correctly, and it certainly won’t reach its ultimate level of efficiency and precision. The time and energy spent on these three process ensure that overall assemblies will require less maintenance, which saves operators and businesses precious time and money.

The Machine that can do it all

One of the most efficient ways of grinding, polishing, and deburring on the market is by using the MAX, an all-encompassing finishing machine sold and manufactured by James Engineering. This deburring and chamfering machine is capable of carrying out all three process concurrently. This means a part can be deburred, ground, and polished in one go. This machine also has a consistent precision unreachable by any hand-done method or other machine. The MAX makes all three processes easy and affordable, which ultimately revolutionizes any operation.

To watch the MAX in action, check out the James Engineering YouTube channel here.

To inquire more about the MAX, call (303) 444-6787 today.

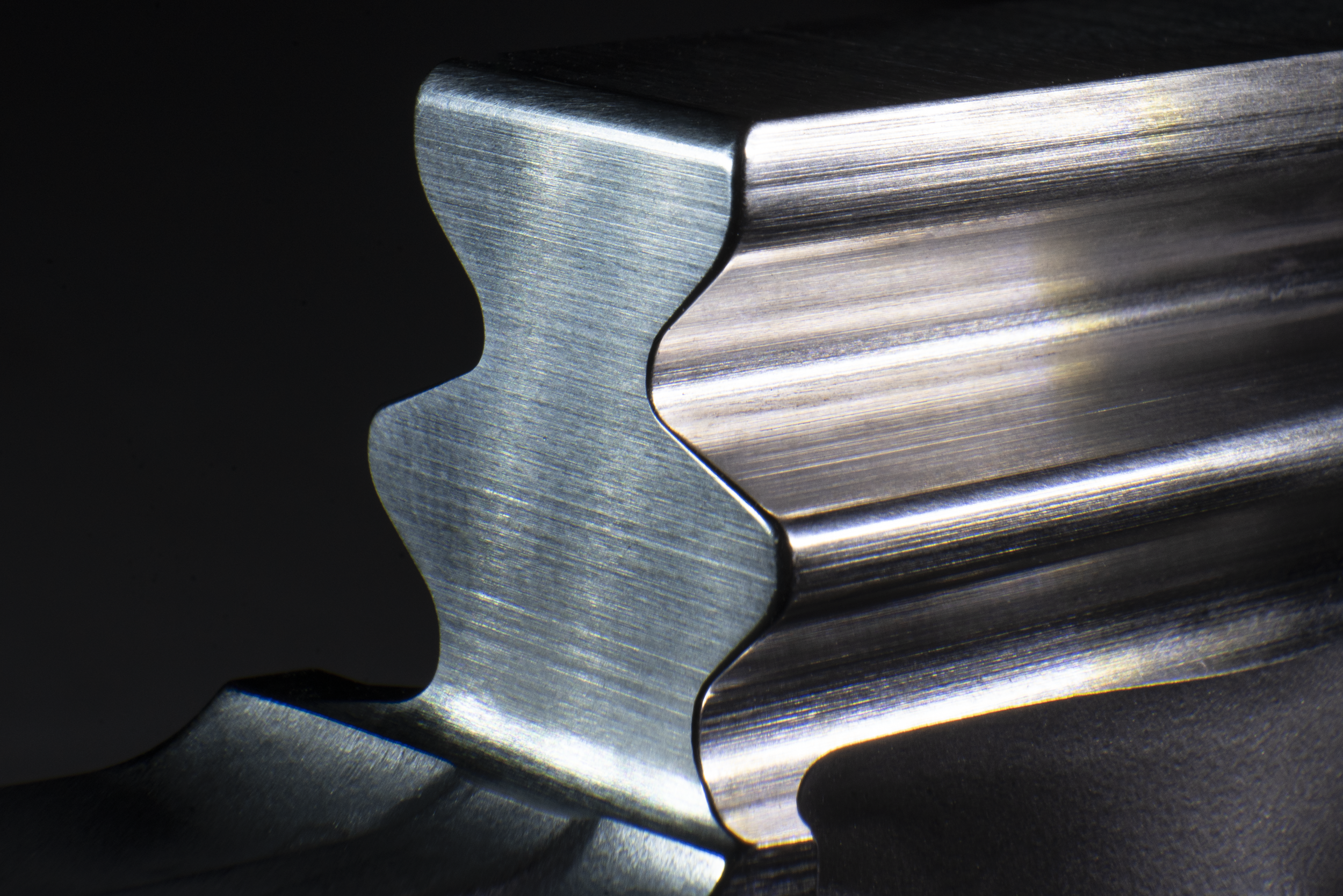

What Is Gear Chamfering?

In simple terms, gear chamfering is the process of cutting a 90-degree edge at a 45-degree angle, but in reality it’s a bit more complicated than that.

Simply put, the process of chamfering is cutting a 90-degree edge at a 45-degree angle as a way to remove stress-rising sharp edges, as well as allow for smoother assembly. That makes chamfering sound easy, when in reality it’s actually very time consuming, no matter the method of approach.

Gear Chamfering can truly be broken down into four separate surface-finishing processes: deburring, chamfering, radiusing, and radius-chamfering.

- Deburring is the process of grinding off burrs, which are bits of excess metal created in the metal cutting process. Burrs are extremely problematic and will cause issues in assembly as well as overall part efficiency. Assuming the deburring has been done properly, all burrs will have been completely removed, leaving nothing but a sharp edge.

- Chamfering, as stated above, is the process of cutting that sharp edge at a 45-degree angle (which is the most common angle, but not the only one they’re limited to). Chamfering can be done with a myriad of tools, such as brushes, sandpaper, grinding wheels, and Scotch-Brite. However, in the process of shaving down this one sharp edge, two more are created on either side of the original, and if the tool being used is worn down, burrs can be created as well.

- Radiusing is the process of completely rounding out edges until it’s completely smooth. While chamfering is smoother than just leaving a part deburred, it still is cut at a noticeable angle that can be seen and felt. Radiusing feels and looks rounded (just like how a ball is round without any hard edge), and can also be carried out via brushes, grinding wheels, and sandpaper. It’s crucial to know what materials these tools are made out of, because the materials will affect the quality of the radius; if a material is too abrasive, it will be impossible to reach a true radius. A true radius is when the edges of a 90-degree angle go tangent to tangent without any surface imperfection.

- Radius-chamfering is when a part receives both radiusing and chamfering. The sharp angle is cut at the usual 45-degree angle, and when those two extra sharp angles are created, they are radiused to create smooth transitions between chamfers.

When it comes to how chamfering is done, there’s a few methods operators can choose from—machine-based, hand-based, or robot-based.

Different types of gear chamfering machines are capable of different sub-categories of chamfering. For example, a CNC machine can decently deburr a part, a lathe can adequately radius-chamfer a part, and a mill can chamfer a part. All of these options are valid, but not a single one of them can chamfer, deburr, and radius a part; separate machines are needed. Not only that, but these kinds of machines require in-depth programming for every single part in order to be exact. The MAX by James Engineering is capable of carrying out all four chamfering processes with heightened precision, as well as little programming.

Doing any of these processes by hand is technically achievable, but it ultimately proves to be more troublesome than it’s worth. Manufacturing is an industry that requires precision, as things will fall apart and fail to work correctly without it, and doing these processes by hand simply does not provide adequate enough precision. Even the best operator can slip or tremble, and man cannot repeatably guarantee a consistent chamfer. Hand chamfering is acceptable in a pinch, especially if only one or a handful of parts require it. But for higher volume operations, not only does hand chamfering not produce consistent results, it also is extremely time and cost inefficient. Scrap rates are the highest with hand chamfering, and the time it takes operators to complete one part is what it would take a CNC to do two or three, or the MAX to do a hundred.

Robots are only slightly better at gear chamfering than when done by hand. While they do have better mobility than most machines, they lack precision. Robots are perfect for operations that require the moving and placing of items, but they just cannot match a machine’s precision. Robots also require a lot of laborious programming, overall making them a poor method of chamfering.

Out of all these methods, the MAX is hands down the most reliable and efficient. As an all-encompassing finishing system, it is capable of deburring, chamfering, radiusing, and radius-chamfering any part or gear, no matter its complexity. It does require some initial programming, but once a part/gear has been loaded in, the MAX will remember it for future use, meaning operators no longer have to manually input adjustments themselves (James Engineering calls these programs “recipes”). The MAX is also capable of repeatable precision down to the fifth decimal. For reference, the average human hair measures to .003 inches. The MAX can repeatably work down to .00001 inches, and even beyond that.

Precision in chamfering is key, because the less precise a chamfer is, it’s more likely that stress risers will appear with continual usage. Stress risers are tiny cracks that form at a part/gear’s weakest point of contact (like the tooth on a gear). If a part is not adequately deburred or chamfered, what will happen is those sharp edges will slowly break off until a part or gear’s structure is ultimately compromised. So that previously mentioned tooth could fall off, for instance. That is extremely dangerous, both for the assembly itself and the people operating it. For example, a helicopter would crash if one of the gears in its motor failed. When it comes to chamfering, the higher the precision, the better. The precision achieved by the MAX means that parts/gears processed through it are extremely unlikely to form stress risers even after years of use.

There’s a misconception about chamfering that it’s done easily. Even with an advanced machine such as the MAX, chamfering is no “easy” feat. If a chamfering operation appears to be “easy”, it’s probably being done sloppily and inefficiently—and precision takes time and effort.

Knowing the correct way to chamfer is a gamechanger with any operation, as well as being able to recognize when a chamfer is done correctly. If it is, parts will fit together with no resistance and work efficiently for the entirety of their lifetime. And when parts work correctly, overall assemblies will perform at their best.

To visibly see how chamfering is done, watch a short video clip here.

To contact James Engineering about the MAX’s chamfering abilities, call at (303) 444-6787

Part Finishing 101: A Beginner's Guide

Part finishing is an in-depth process requiring multiple different applications to ensure parts are processed to perfection.

Every piece of machinery is made up of a thousand smaller pieces all continuously working together to accomplish the same goal. Every single one of these pieces need to go through the part finishing process, which ensures they work correctly and keep the overall operation running smoothly. “Part finishing” is an umbrella term for all the individual processes and techniques that go into the ultimate completion of these parts/gears.

Machining

First, let’s start with machining. This is where gears/parts are initially manufactured out of blocks of raw material. CNC (computer numerical control) machines do most of this work, and there are multiple different kinds of CNC machines, such as milling machines, lathes and turning machines, laser cutting machines, etc. Excess material is carved away by these machines to reveal the rough shape of whatever gear/prismatic part is being created. Once this first step is completed, the nitty-gritty side of part finishing begins.

Deburring

Deburring is the process of removing burrs from the edges and surfaces of these freshly cut parts/gears. Burrs are sharp bits of excess metal that will eventually ruin the integrity and overall quality of whatever part/gear they’re stuck to. This process can be done by hand, in a CNC machine, or a machine made specifically for deburring*, such as a James Engineering machine. Deburring is one of the most crucial aspects of part finishing, as many other processes cannot be done if a part or gear is not deburred properly.

Surface Grinding

This process creates smooth surface finishes on metal and non-metal parts alike. It’s an abrasive process which uses grinding wheels to shave down any surface impurities that might affect the functionality and aesthetic of a gear/part. Grinding wheels (add link to website page here) come in a variety of sizes and materials, which directly determine a wheel’s grinding intensity. Grinding surfaces are crucial when it comes to achieving tight part tolerances, as it ensures a part will fit perfectly within its environment. Surface grinding will also rid a part/gear of any corrosive layers that may negatively affect its overall durability.

Polishing

Polishing is done to further smoothen a part’s surface. What makes polishing different from surface grinding is that it’s meant to enhance surface quality, whereas grinding is used to remove extra material. Polishing is also an abrasive process, and it uses polishing pastes and abrasive pads. Polished parts are reflective and more resistant to corrosion, which makes it a crucial step in the finishing process for items such as car bumpers, medical equipment, mirrors, and more.

Buffing

Many people get buffing and polishing confused—but it’s fair considering how alike these two processes are. What makes them different is their levels of aggression. Buffing is the more aggressive of the two, and can actually remove surface material if done too hard. It can be used to remove shallow scratches, and unlike polishing, it will not leave a highly reflective surface. Buffing is frequently used in the automotive, jewelry, and electronic industries.

Chamfering

This step of the part finishing process is extremely important, especially for pieces with right-angled edges. Chamfering is when these edges are cut at a slope, which later makes assembly easier and reduces the amount of stress risers within a gear/part. Sharp, non-chamfered edges can snap and break off, leading to loose material floating throughout a machine. This debris could ultimately affect the efficiency of the entire machine, and even cause it to fail completely. When edges are chamfered, the likelihood of such an occurrence is reduced drastically. It will also ensure that pieces fit together more snugly, reducing the risk of the parts themselves becoming too loose.

Brushing

Brushing can be categorized as a type of deburring, as it can technically get rid of excess burrs left on the surfaces of parts. But that’s not its man job—brushing is used as a way to further perfect part surfaces, as it preps parts for coatings and rids them of any external contaminants, such as oils, dirt, residue, etc. It is also a very precise process in the sense that if only one small section of a part/gear needs further surfacing, a brush can stay focused on that specific spot without affecting the rest of the gear/part’s body. An important thing to remember when it comes to metal brushing is that certain brushes must be used on certain metals; for example, stainless steel can only be brushed with steel brushes. But other materials, such as rubber and leather, can also be brushed if need be.

Sandblasting

This process is also known as abrasive blasting, as it can be done with many other substances other than sand, such as glass beads, water, dry ice, and compressed air. This is another technique used to smoothen, decontaminate, and shape surfaces. This technique of part finishing comes from the naturally occurring phenomenon called aeolian erosion, which is when an environment’s geography is changed and shaped by consistent winds. Blasting is done manually when a blasting substance is mixed with air in a pressurized chamber and dispensed through an abrasive-proof handheld nozzle.

Washing

The washing process works exactly how you’d think it would—a mixture of hot water, solvent, or washing fluid are dispensed either by hand or by a machine over freshly-processed parts to clean them of excess swarf. It’s important to wash parts of debris because, as mentioned above, debris can drastically decrease the effectiveness of a part/gear and the greater machine it was assembled into. In order to avoid corrosion or rusting, special fluids must be used to protect both the part being washed and the machine doing said washing.

Overall

Machining, deburring, chamfering, washing, brushing, surface grinding, polishing, buffing, and sandblasting are the most common part finishing processes in the manufacturing industry, but there are still a variety of methods used that were not mentioned. Each process has its own unique use, and it’s crucial that manufacturers understand what method will produce the strongest outcome for a part or gear.

How James Engineering Part Finishes

Here at James Engineering, we are experts when it comes to the varying methods of part finishing. We manufacture and sell all all-encompassing surface finishing and chamfering machine known as the MAX System, and it’s got you covered completely—the MAX can deburr, chamfer, wash, brush, and even radius parts/gears of various sizes. The best part is the MAX can carry out multiple processes at once, which exponentially cuts down on processing time and leads to a higher production volume.

If you’d like to experience the effortless efficiency of a multitasking finishing fiend, contact us at Sales@James-Engineering.com and we will send you a quote!

*For being such a vital part in the finishing process, deburring machines are an extremely niche market of their own. James Engineering specializes in deburring and chamfering machines and offers a variety of systems at competitive pricing. Click here to learn more about the different kind of systems we manufacture.

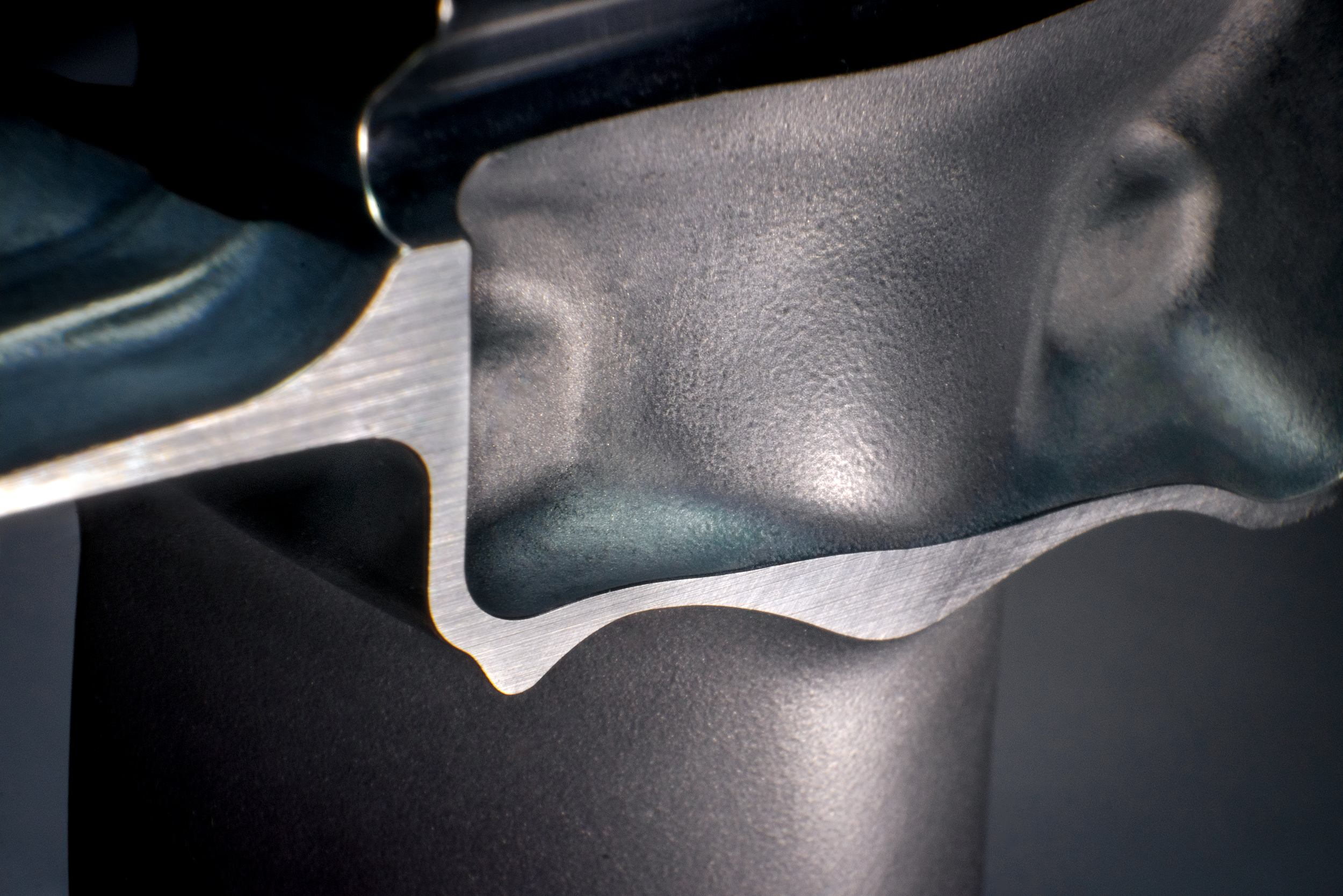

The Matter of The Sprocket

Sprockets can be tricky to deburr, but James Engineering has come up with the perfect solution.

Sprockets are an extremely common and useful gear used in everyday applications, such as bicycles and motorcycles. Some of the earlier automobile models even used them, taking inspiration from the mechanics of bikes!

A sprocket transmits rotary motion by locking its many teeth into a chain and driving it and therefore moving any other parts also connected to said chain. Sprocket gears can have multiple strands, meaning they can attach to multiple different chains at once, and have anywhere from 17 to 114 teeth. Anything above or below those numbers are inefficient.

Sprockets can either be made with or without hubs. Hubs are the thickness seen on either face of the sprocket and are separate from the teeth. The thicker the hub, the more torque the sprocket can transfer.

There are a few types of sprockets, each needed for different applications:

· Type A: These are flat with plain bores. This means they have no hubs at all.

· Type B: These sprockets have only one hub on one of their faces.

· Type C: These have two hubs, one on each face of the sprocket, and they are both equal in their thickness.

· Type D: These sprockets also have two hubs, one on each of its faces, but one is thicker than the other, offsetting it just like a Type B sprocket is offset.

If the wrong kind of sprocket is used (i.e. if its hub is too thick to fit snugly against equipment, or if its number/thickness of teeth don’t match with a chain’s tooth pitch), the entire chain assembly can fall apart, or cause time and money consuming shutdowns.

Sprockets pose a unique challenge when it comes to finishing them properly.

These big-or-little gears require intense attention to detail, which is vital for their function, but time consuming and costly. Normally, a sprocket would have to be deburred, chamfered, and brushed by hand or in a manual machine. These options are fine in some scenarios, but for a production business, these options will ultimately slow you down and disrupt the flow of operations.

A machine such as the MAX System greatly outpaces any manual and hand operations, especially when sprockets are involved. The MAX will process a sprocket of any size in up to 10 seconds. Two major features of the MAX allow for this amazing processing time: its capabilities to run multiple tools concurrently, and its ability to program part adjustments for future use.

The recipe programming of the MAX singlehandedly makes it a standout machine. It will take operators anywhere from 5 to 10 minutes to adjust the machine to a specific part, and once they have, the MAX will remember said adjustments and save them for future use. It can save a multitude of different part recipes, making it ridiculously easy to change out parts, no matter how drastic size differences/requirements are between them. Because sprockets are such tricky parts, this saves businesses an abundance of precious time.

The MAX also offers both wet and dry options. The machine will run beautifully either way, so it’s ultimately a matter of preference. However, the wet option is fantastic if you’re worried about flammable debris and how it can affect your machine. The wet MAX comes with rust-inhibiting solution so as to not damage machine or part, and it quickly washes away any debris before it becomes an issue. No debris will ever get caught between the teeth of sprockets of any size.

Sprockets can be a manufacturer’s nightmare, but they don’t have to be. The MAX System by James Engineering is built with efficiency and precision in mind, meaning it can take any sprocket with ease.

Watch the video below to see how all of this works in real-time.

High speed precision deburring for quick production

The Dynamic Duo

Why a CNC machine and the MAX System make the perfect pair.

As the demand for parts grows exponentially within the manufacturing industry, so does the need for expert deburring and chamfering. James Engineering manufactures an all-purpose finishing system known as the MAX System that is meant to be paired with CNC machines to produce parts of the highest caliber.

“The MAX is meant to compliment CNC machines,” explains Scott Richards, Vice President of James Engineering. “The MAX allows CNC machines to do what they do best: make parts.”

While CNC machines can deburr parts, they tend to be choppy, aggressive, and slow at it; their primary function is to cut. This means high-volume shops are extremely limited when it comes to both the quality and quantity of parts they’re producing (that is if they rely on CNC machines to deburr as well). The MAX is the solution to this problem—it leaves cutting to the CNC machines and does everything else. “We’re not trying to make a metal cutting machine, or a part manipulator. We’re making a machine that does a delicate job quickly in a way that hand deburring, and CNC machines, can’t,” says Richards. So once the CNC machines can focus solely on cutting, a higher volume of parts can be produced in one day, ultimately heightening a company’s productivity as well as increasing their overall part quality.

Not only does the MAX make overall processing easier, but the machine itself is easily operatable, especially for those who have prior experience with CNC machines. “Within four minutes anybody could learn how to use the machine,” Richards states, “We teach these machines to move into position conversationally, have it catch that point, then move to another position. This is unlike CNC machines, or even robots. If someone new wanted to run a CNC machine, they’d have to understand the language the program is written in; we do not run M- or G-code, we use conversational programming.”

Deburring in a CNC machine can be inaccurate and slow-moving—but that’s because deburring isn’t the main function of a CNC, cutting is. The whole purpose of the MAX is to take the weight of deburring off CNC machines. So while the CNCs focuses on expertly cutting parts, the MAX deburrs, chamfers, brushes, washes, and surfaces all in one go after said parts have gone through the CNC. The MAX will pick up a CNC’s slack, and vice versa, making them the perfect pair. The duo will drastically reduce cycle times while still producing a high volume of expertly processed parts with focus, and without the sacrifice of integrity. For any shops out there running into issues with CNC deburring, or for companies who would simply like to increase their productivity overall, investing in the MAX is the next step you need to make.

Everyone needs a best friend, even machines. Give your CNC its best buddy today and inquire at Sales@James-Engineering.com as to how you can bring your MAX home.

The Grind Never Stops

It matters what your grinding wheels are made of.

Grinding wheels are vital in the manufacturing world—they’re how machinists polish rough edges and achieve consistent chamfers. The size and abrasiveness of these wheels very depending on what materials they’re made of. This will directly correlate with what gears/parts the wheels are used for.

Here at James Engineering, we have an extensive stock of various grinding wheels and sell them at competitive prices. Let’s get into the 3 main wheels we sell and why you need to know the difference between them.

—

1. The Woven Fiberglass Wheel

This is your typical grinding wheel made from a homogenous blend of aluminum oxide and powdered resin. The tops and bottoms of these wheels are pressed with fiberglass, which acts as a strengthening agent and ensures the wheels don’t break while spinning.

Pros: They’re quick, and they’re aggressive, meaning their time efficient and great for cutting.

Cons: They can sometimes be a little too aggressive. These wheels can cut too deeply and have an extreme tendency to bounce, as they have no dampening factor.

2. The Woven Cloth Wheel

This wheel is comprised of cotton, liquid resin, and aluminum oxide. You might be thinking, cotton, really? But it really works! Strips of cotton cloth are layered between layers of resin, and these many layers keep the wheel’s structure from falling apart.

Pros: These wheels are great for chamfering due to the fact they don’t bounce nearly as much as fiberglass wheels do since the cotton acts as a dampening agent. The fact that they’re softer, and don’t have as much bounce, means the parts/gears they’re working on can be spun at faster rates, achieving a quicker and smoother chamfer.

Cons: They’re a bit too soft for cutting. Believe it or not, cotton isn’t very sharp.

3. The Woven Carbon Fiber Wheel

This is the most unique wheel sold at James Engineering. In fact, it’s so unique and rare that we are the only ones to carry it! These wheels are made of carbon fiber and resin, and nothing more. There’s no abrasive added to them, but the carbon itself acts as a very mild abrasive.

Pros: They’re perfect for those with very niche needs. They create extremely subtle chamfers and have beautiful surfacing abilities. They’re also great to use at trade shows because they won’t tear apart gears or non-gears during demonstration.

Cons: They’re very, very gentle, so they can’t do very much. Since they have no abrasive added to them, they make cutting and grinding a drawn-out process—essentially, they’re mostly for people who need very petite chamfers.

—

Whatever your grinding needs consist of, James Engineering will help you find the most perfectly-fitting wheel. We’ll even send you a sample or two!

If you’re interested to know even more about the different kind of grinding wheels we sell, check out https://www.james-engineering.com/grinding-wheels.