The Machine Shop at James Engineering

Get an inside scoop about the machine shop at James Engineering from a Q&A with lead engineer, Dave Schlosser, and company vice president, Scott Richards.

The Colorado-based OEM shop is known for their one-of-a-kind deburring and chamfering machines, but they also have a precision-focused machine shop that’s willing to take on any project that comes their way. If you’re in the market for a low to medium volume machine shop who guarantees quality products, reach out to James Engineering today at (303) 444-6787.

—

What is our shop capable of?

Dave: We have 3 mills and 2 lathes. One of the mills has 4th axis capability. We’re capable of holding concentricity within 5/10ths in most cases without have to do any crazy set ups. We can do round parts, square parts, just about any shape part that you want.

Scott: We’ve got a live tool lathe with a bar feed option and multiple seats of programming software. We’ve got that 4th axis mill, another smaller mill with a 20-inch bed, and we’ve got a 60-inch bed large mill.

How many parts a week do we typically make?

Dave: That’s pretty subjective because we do short run production, so most of our time isn’t spent making parts, it’s getting ready to make a part and getting a part set up to run. Typically, we could spend half hour programming, half our setting up, and basically we could run for 15 minutes and then be done (in some cases). We can’t really quantify the quantity of parts per week because we’re more set up to be a tooling or prototype shop versus a production shop.

Can customers send in their own designs?

Dave: We quote on stuff and have stuff made for outside companies. We have engineering services, so people can send in a concept and we could do the whole thing, or they could send in a thing that’s basically done and we could create drawings for them, things like that. We have start-to-finish capability, or we can pick up a project that they’re already halfway through. We can also provide good drawings, give them a model.

What are some basic jobs we do frequently?

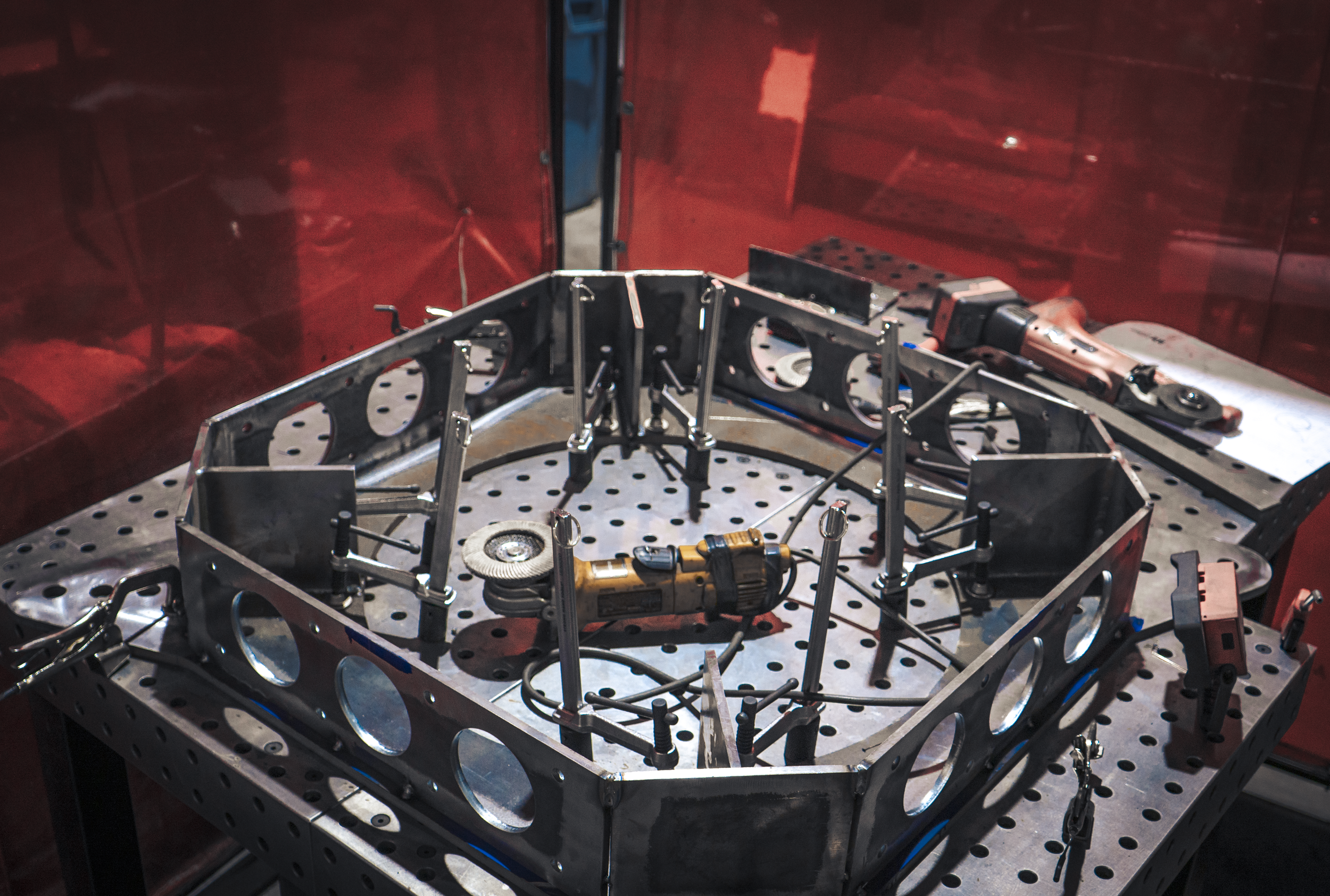

Dave: We do a lot of gun parts, automotive stuff, motorcycle parts. It really is just a gamble. Basically, anybody who walks into the door with a project, we can take a look at it and see if it fits our capabilities fairly easy and we’ll do it. We’ve done a lot of welding jobs lately, too. We’ve done a lot of stuff for RoboCon; we’ve made a lot of platforms and fixturing. We’ve made brownie bowls, and stuff for volleyball companies, it doesn’t really matter what industry comes in.

Scott: So we’ve got a lot of high end, high precision parts that we make. For example, we’re making a mount for a vehicle right now. Our perfect job is a volume job. We’re really looking for anything from prototype to a few thousand parts a week. I wouldn’t call ourselves high volume where we’re tens of thousands of parts per week, but we’re definitely looking for that low to medium volume area.

What makes our shop stand out?

Dave: Our attention to detail and the quality of our parts. That’s something that we take a lot of pride in. We try to go that one step above, whether it’s by deburring or not putting a scratch on it by pushing it across surfaces, things like that. We take really good care of all the parts we make, and it’s a lot easier to go in and get the quality you’re looking for when you’re not making thousands and thousands of parts.

Why is it significant for our machine side of business that we make our own parts in-house?

Dave: We can control our own quality because our standards are really high. To be able to get the tolerances and stuff we need we can hardly get other people to make them for us. We put a dimension on a drawing and expect you to hold it, so in some cases we put really tight tolerances on things with reason, and when other companies see those tight tolerances the cost goes up automatically (whether it’s justifiable or not). It’s more cost efficient for us to do it.

Scott: We have to make all of these parts here in-house because we really can’t afford to job much of this out. We’ve got to keep our profit margins where they need to be. We have to hold pretty precision fits because we’ve got a 3.2 million resolution encoder here turning all of these [parts] on this five-axis manipulator.

How do your own deburring machines fit into the machine shop process?

Scott: When we make these parts, we do a lot of in-machine deburring. We’ll go through and we’ll machine this edge with a chamfer tool. But the problem is, when we machine the edge with the chamfer tool, the chamfer tool creates two sharp edges. We still have this problem where a technician has to go in with Scotch-Brite and deburr this. So we don’t want that abrasive to get into our CNC machine, because if that abrasive gets into our machines, it gets down into ways and slides and it wears the machine out. That’s where the market is for our deburring machine.

Deburring Debunked: The Ultimate Challenges

Jim Richards, founder of James Engineering, explains the top three part finishing challenges and the secret to overcoming them.

The process of finishing parts and gears before assembly comes with a set of its own unique issues. This manufacturing process is vital and cannot be skipped, or else assemblies would fail due to poorly prepared parts/gears. Finding simple, efficient solutions to these issues is crucial, as it ensures overall effectiveness and quality of an assembly.

We interviewed Jim Richards, the founder of James Engineering, and asked him what he finds to be the top three part finishing challenges. Richards has been at the forefront of the deburring industry for a little over forty years and is seasoned when it comes to overcoming a challenge.

1. Conflict with Customer Prints

“One of the biggest challenges is meeting customer requirements within blueprints,” Richards says. “Sometimes, the people writing these specifications don’t understand the tooling that is required with deburring or how it works.” Richards later goes on to say that this particular issue is not only the hardest one to solve, but the most common one faced within the deburring industry. The process of deburring is very complex, and if blueprints aren’t drawn correctly, deburring can seem impossible on that specific part because of the ultimate limitations that come with the process. “Sometimes we don’t have the kind of tools to do what the blueprints ask of us,” explains Richards, “but we’ve learned to solve these problems over the years.”

What Richards has learned is that collaboration and adaptability are key when it comes to sidestepping this conflict. The engineers at James Engineering are in constant contact with their customers in order to meet their requirements in achievable ways. “Sometimes we get companies who send in drawings that we absolutely cannot change,” Richards adds, “Take Pratt & Whitney for example. That’s a big company that requires consistency, we can’t just up and change what they’ve sent us. So we have to do what they’re wanting us to do. But we’ve learned to do the job.”

2. Cost of Consumables

“Understandably, you can’t build a quality part with cheap materials,” Richards starts, “Sometimes you have to spend a little more to get a better part.” Richards explains that every James Engineering machine is built with the intention of using particular brands or items. If these specifications aren’t followed, the final quality cannot match what is promised by one of their machines. “The quality of chamfer we need and produce is from running a finer grit grinding wheel,” Richards explains when asked for an example. “The wheels we use are made of cotton, which don’t last as long as these tiger claw, aluminum oxide coarse wheels. Well, these coarse wheels remove metal fairly easily, but they leave a really jagged finish. People run these wheels for economic reasons, because yes, they’re cheaper, but they will destroy a part.”

James Engineering machines are known for producing beautifully precise and consistent chamfers. This is greatly due to the kind of grinding wheels they use, which are comprised of cotton and resin. The idea of using cotton in a grinding wheel is surprising to many, but in terms of chamfering, this kind of wheel is a champion of it. The cotton acts as a dampener, meaning these wheels’ tendency to bounce is extremely low, especially compared to woven fiberglass wheels. While the cost of running these coarse fiberglass wheels is smaller up front, it will actually cost a greater amount in the long run due to a high rate of scrapped parts. This is a great example as to why using the intended tools is extremely important for overall production. “We have to establish what we’re going to use and that has to be followed.”

3. Consistency of Parts Presented

The third most frequent challenge Richards has seen is the consistency of parts presented. “We often get sample parts from customers, and their conditions will sometimes change. So then we have to take samples of burrs and look at their size and decide what we can and cannot do. I’ve seen samples come in with burrs an inch and a half tall!” Essentially, machines are manufactured to handle a consistent, established size of burrs for specific parts. For example, a company will send in a dozen samples of the same part. Eleven out of twelve of these parts have burrs roughly the same size, but the twelfth will have a burr substantially larger than the rest. This twelfth part wouldn’t receive complete deburring using the same specs as the other eleven parts—it would require an entirely different set of measurements, tooling, and time. But this issue is easily avoidable as long as customers take care of one particular aspect: changing the part cutter on their CNC machines.

“When you’re making a gear or part, the hob cutter will start off as razor sharp, but it eventually wears out, naturally. We [at James Engineering] have to make sure we qualify when you change your cutter. Operators can’t be running their cutters down to total wear then give us huge burrs. So we need to establish the point of which they change their cutter so we receive parts that we’re capable of deburring.”

This may sound laborious and costly, but again, this ultimately saves money in the long run. If cutters are changed regularly, the predictability and consistency of their parts becomes manageable. This then makes it easier for James Engineering to manufacture machines that work perfectly for a shop’s needs. If the cutter is not changed frequently, extra tools must be added to a shop’s machine, costing them more in money and processing time. “You’re better off to change the cutter and leave our process simpler,” Richards explains.

So, how avoidable are these challenges?

“These are all very easily avoidable!” says Richards. “With consistency of parts presented, we just need to qualify the part that we’re going to deburr and establish that in writing. With the cost of consumables, we have to establish exactly what we’re using and write it into the warranty. Conflict with customer prints is always trickier, as we sometimes can’t change anything about the blueprints we’re sent. [We just] have to be adaptable.”

James Engineering prides itself on being a thorough and precise business—these values can be found at the core of the company. They are what make their machines so consistent and products so repeatable. There’s a reason why their deburring systems are at the top of the market.

What are the ultimate solutions?

With each customer comes a new challenge, but conflict with customer prints, the cost of consumables, and consistency of parts presented are usually given. However, after decades of dealing with the same issues, Richards and those at James Engineering have found that the following are the top solutions:

· Adaptability

· Reliability

· Flexibility

· Thoroughness

· Consistency

· Communication

By adhering to these six simple values, no challenge is too much for James Engineering.

To learn more about their machines, click here.

To send any sales inquiries or further questions, email Sales@James-Engineering.com