Mastering Deburring: From Micro Parts to Massive Gears

In manufacturing, the size of parts can pose substantial challenges when it comes to deburring and chamfering processes.

In manufacturing, the size of parts can pose substantial challenges when it comes to deburring and chamfering processes. Whether you're a manufacturer dealing with delicate medical micro components, large mining gears, or life critical aerospace and defense parts requiring precision, finding the right deburring machine is critical. At James Engineering, we specialize in deburring solutions tailored to handle the diverse needs of modern manufacturing.

Deburring Machine for Small Parts and Micro Components

Deburring and chamfering small parts and micro components demand precision and finesse. Our surface finishing machines are designed with advanced compliance technology to cater to these exacting requirements. From intricate micro parts to precision components, our machines ensure consistent and high-quality results every time. Fully automated features reduce human intervention, freeing up your workforce for more specialized tasks.

Deburring Machine for Large Gears

Dealing with large gears presents unique challenges in deburring and chamfering. Our specialized large gear deburring machines are equipped to handle these massive components with ease. Automated processes streamline operations, delivering efficient and reliable results while reducing manual labor costs. Consistent deburring of large gears ensures optimal performance and longevity in your machinery.

James Engineering redesigned their famous MAX System with an open back to accommodate large gear deburring and chamfering

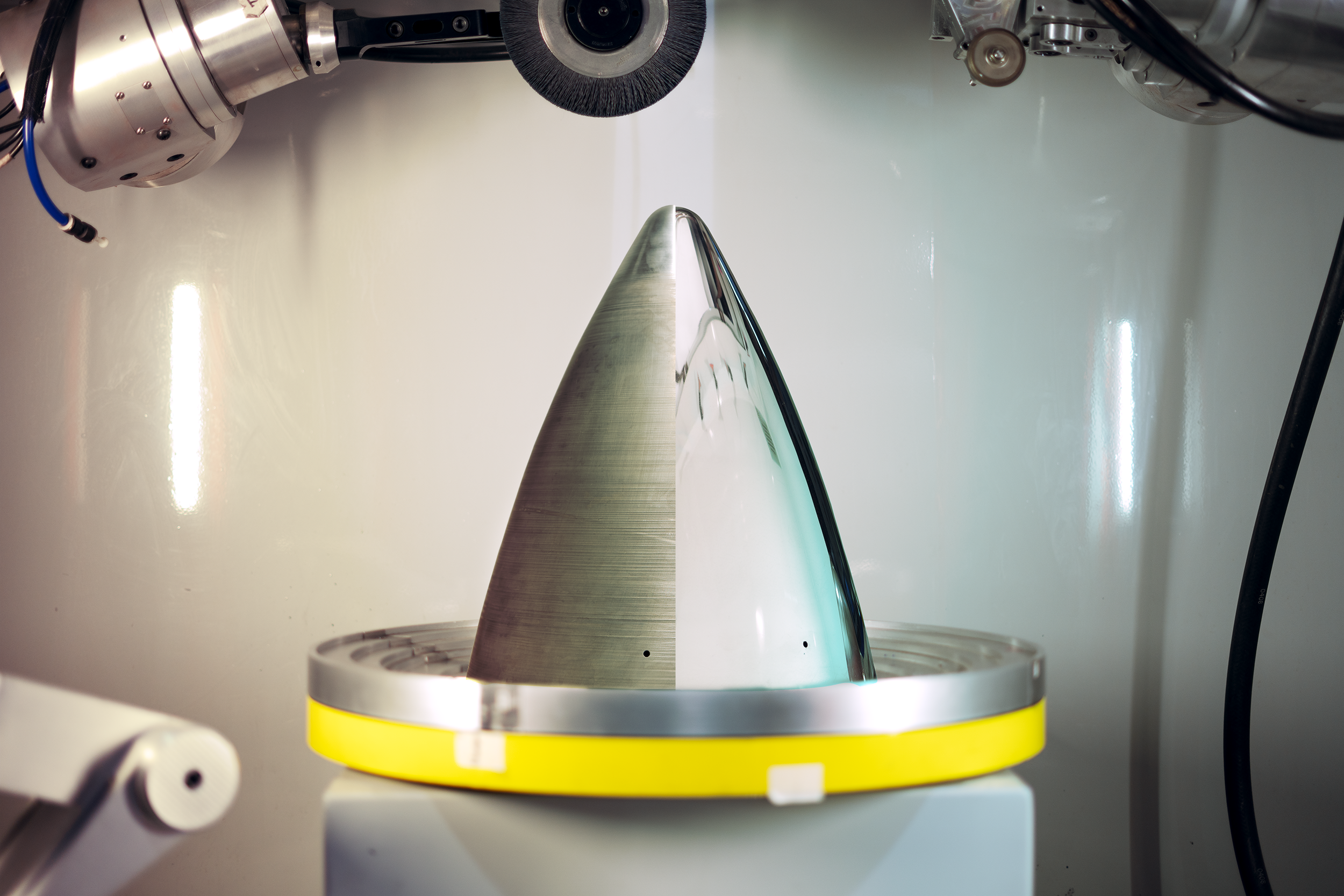

Deburring Machine for Aerospace and Defense Parts

In the aerospace and defense industries, precision is non-negotiable. Our deburring machines are engineered to meet the stringent demands of these sectors. Whether deburring intricate aerospace components or critical defense parts, our machines deliver unparalleled accuracy and repeatability. Customizable settings allow for precise adjustments to match specific part requirements, ensuring adherence to strict industry standards.

Wide-Range Surface Finishing Machines

Don't let part size limitations hinder your manufacturing excellence. James Engineering offers specialized deburring machines tailored for small parts, micro components, large gears, and aerospace/defense parts. Experience consistent quality, efficiency, and cost-effectiveness in your deburring processes.

Do I need a Chamfer Machine or a Deburring Machine?

Learn the difference here

Contact us today to explore how our advanced surface finishing technology can elevate your manufacturing operations across diverse part sizes and industries.

Master large gear deburring or small gear finishing with James Engineering's complete deburring solutions!

The Difference Between Grinding, Polishing, and Deburring

These three machining processes all seem frustratingly similar—so what makes them different from each other?

Grinding, polishing, and deburring—anybody who knows anything about the precision machining process knows that these three processes are a.) crucial, and b.) acts of surface finishing. These three processes are very similar to each other, and for decades have been making people ask the same questions: What’s the difference? And why do we need to do all three processes? Both of these questions are valid, and we have the answers to both below.

The difference between grinding, polishing, and deburring.

1. Grinding

This is the process of removing material and shaping a workpiece into its final form. Grinding can be done on a multitude of materials, such as plastic, ceramic, and many different metals (stainless steel, titanium, high-nickel alloys, etc.). In order to complete this process, grinding wheels of different abrasives are used in various machines made specifically for grinding. It’s important that the correct kind of abrasive is used, as too soft of an abrasive can’t grind a workpiece enough, while too hard of an abrasive will damage a workpiece and result in decreased part quality or scrapped part. Overall, grinding is essential because it improves a part’s surface finish, which not only provides the aesthetic many industries require, but also ensures the removal of pesky surface imperfections.

2. Polishing

Polishing is the process surface finishing, which is also known as the process of improving surface quality. Using softer, smaller abrasives like polishing compounds and wheels, surface imperfections such as scratches and unwanted film/layers are removed to achieve a part’s desired texture (as different industries require different surface finishes). Polishing can be done by hand, machine, or robot, as it doesn’t require quite as much precision as grinding or deburring do. This step can be taken farther with buffing, which gives parts a finish similar to that of a mirror.

3. Deburring

This process is the act of removing burrs from a part’s surface. Burrs are extra bits of metal that form as a part is being cut, and can be extremely harmful both for a part’s functionality and the overall assembly it’s a part of. Deburring can be done by hand or in a machine, though hand deburring proves to be inconsistent and costly. The process of deburring requires extreme precision, as any leftover bit of metal can cause inconsistencies that result in the decrease of a part’s longevity and efficiency. Deburring is required for any part that has been previously machined and can be done on a variety of different materials, such as ceramic, stainless steel, wood, titanium, and more. What makes it an essential process is it ensures parts meet industry standards and helps reduce the possible formation of stress risers.

Surface Profiling

Seeing as all three of these processes fall under surface finishing, it’s important to know how surface finish is measured. Surface profiling is the measurement of a surface’s roughness, which allows manufacturers to know how adequately prepared a part is for further processing, especially when it comes to the part coating and assembly stages. A profilometer is the tool used to measure these surfaces and can be split into two categories: contact and non-contact. Contact profilometers use a stylus to map out the highs and lows of the surface (also known as peaks and valleys) which allow operators to gauge how smooth or rough a workpiece surface truly is. A non-contact profilometer uses image sensors to detect a surface’s texture. While this is the faster of the two profilometers, it’s extremely sensitive to any dirt or oil that may be coating a part’s surface.

Why does manufacturing require all three processes?

Ultimately, grinding, polishing, and deburring are all needed for the same reasons: dimensional accuracy, part efficiency, corrosion resistance, and improved functionality. All of these processes refine parts so they’re safe, functional, and meet industry standards. In other words, it’s the manufacturing equivalent of editing a piece of writing before publishing. A part might work fine enough after it’s just been cut, but without grinding, polishing, and deburring, it probably won’t fit into its assembly correctly, and it certainly won’t reach its ultimate level of efficiency and precision. The time and energy spent on these three process ensure that overall assemblies will require less maintenance, which saves operators and businesses precious time and money.

The Machine that can do it all

One of the most efficient ways of grinding, polishing, and deburring on the market is by using the MAX, an all-encompassing finishing machine sold and manufactured by James Engineering. This deburring and chamfering machine is capable of carrying out all three process concurrently. This means a part can be deburred, ground, and polished in one go. This machine also has a consistent precision unreachable by any hand-done method or other machine. The MAX makes all three processes easy and affordable, which ultimately revolutionizes any operation.

To watch the MAX in action, check out the James Engineering YouTube channel here.

To inquire more about the MAX, call (303) 444-6787 today.